Practical recommendations

33

DRILLING INTO STRAW INCORPORATED SOIL AND TRASHY

CONDITIONS

In heavy trash conditions it may be necessary to raise the tip of the seed tube coulter so that the disc will cut

through the trash before the coulter opens the slit. In heavy maize trash, especially in the direct drill or no-till

situation, it may be necessary to raise the tip of the seed tube coulter 30 to 40 mm above the edge of the

disc. The discs cut through the trash very positively. The weight of the press wheels keep the discs anchored

and do not allow the discs to ride out of the soil, even when there is a lot of trash present. Bulldozing

normally occurs when a disc meets trash, tries to ride up over the trash, then pushes it in front of the disc,

thus causing bulldozing and blockages. If this happens it is usually due to the soil underneath being too

loose. The drill will cut cleanly through, given that it has something to “bite on”. Consolidating the field with

either rollers or a land packer, sufficient to allow the drill’s discs to turn, will usually cure the problem. A

speed of 9 - 11 Km/hr works, 7 - 8 Km/hr doesn’t.

The trash itself especially chaff, on decaying, produces acids, toxins, etc., which tend to damage or kill the

germinating seed. If the trash is mixed with the soil and consolidated tightly to give a good straw/soil contact

then the soil will absorb the toxins as they are formed , before they can harm the germinating seedlings. The

press wheels on the UNIDRILL consolidated the trash, soil and seed in exactly the right manner to give very

healthy plant stands even in the heaviest incorporated residues. If straw is incorporated into the soil to leave

a loose fluffy seedbed then it must be consolidated first using either a roller or land packer, etc, before

drilling.

MINIMUM TILLAGE AND DIRECT DRILLING

In certain soils, especially if they contain stone or brash, it is recommended that the top 1” or 2” should be

cultivated or scratch tilled. This will encourage the germination of volunteer cereals and weed seeds. It will

also help to level out the tramline and wheeled tracks. Also if stones are left undisturbed in the top layer, they

become embedded and the disc will ride from stone to stone without getting good penetration.

In soft field conditions it is essential to set the discs deep enough to cut through all the matt or surface trash.

Seed will germinate and grow better when in contact with the soil. In wet, soft conditions the disc may be set

to penetrate deeper than required. As the drill moves forward the seed is trapped by the sides of the slit and

do not necessarily fall to the bottom of the slit.

DIRECT DRILLING GRASS PASTURES

Four methods are suggested for direct reseeding grass into grass pastures

.

A.

If the pasture has been badly poached or there are bare patches due to frost kill etc., over

the winter, about 110 Kg/Hectare of a vigorous growing type of grass (e.g. Italian Rye

Grass) should be drilled just before growth starts (March / April).

B.

Where a first cut or second cut of silage is being taken, cut low to the ground and direct

drill the new grass mixture the next day. There should be enough moisture retained in

the soil to germinate the seed and get it growing before the cut sward can fully recover.

C

. Graze the pasture as bare as possible, then spray Gramoxone (1.4 Litres/Hectare) and

direct drill the new seed mixture. The Gramoxone used at a low rate will not kill all the

old grass sward but should retard its growth sufficiently to get the new seeds established.

Where the old pasture is very weedy and a complete reseed is required, spray with

Roundup to get a total kill of vegetation. Leave the field for the recommended period

and direct drill with the new seed mixture. To get a better grass cover, cross drilling at

an angle (30 - 45 degrees is recommended, especially with the wider row spacing

UNIDRILLS. Check the reseeds for Leather Jacket, slug or fruit fly damage and treat

accordingly. Grass sown after 1st August should be sprayed with pre-emergence with

Dursban or Spannit to protect from fruit fly and leather jackets. Slug pellets should be

used as required.

Summary of Contents for 240G

Page 9: ...Safety Instruction Decals Safety Stickers 9 ...

Page 10: ...Safety Instruction Decals 10 ...

Page 11: ...Safety Instruction Decals 11 25 ...

Page 12: ......

Page 22: ...Settings A Distribution Settings Size metres 2 40 3 00 Turns 62 5 50 22 ...

Page 37: ...Flow Rate Tables Calibration Procedure 37 ...

Page 38: ...Flow Rate Tables Calibration Procedure 38 ...

Page 39: ...Flow Rate Tables Calibration Procedure 39 ...

Page 40: ...Flow Rate Tables Calibration Procedure 40 ...

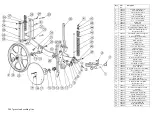

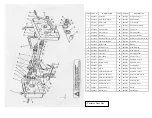

Page 43: ...Grassland Parts booklet 2007 grassland seeding line ...

Page 45: ...Grassland Main Chassis ...