Settings

F : Half Width Shut off

c)

d)

The hopper must be emptied after work, to avoid rodent damage.

c)

Half-seed drill disengagement

-

Only the right side is declutchable.

-

Remove the clip. Pull lever (1) and put clip (2) back in place.

-

After completing your ½ pass, do not forget to re-engage the lever. Make sure both shafts

are rotating again.

d)

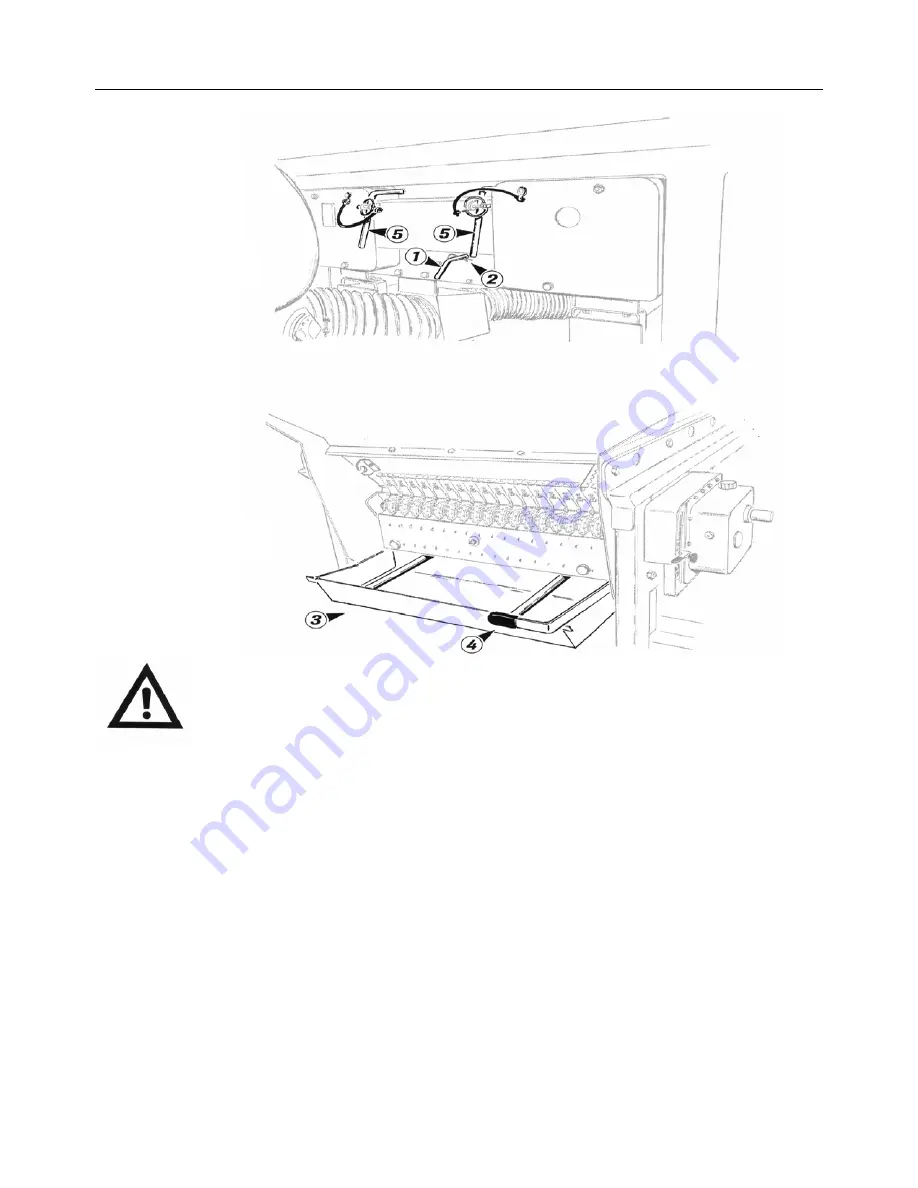

Emptying the hopper

-The hopper is emptied into tray (3)

-

Position the tray under distribution and lower lever (4) all the way downwards.

-

To stop seed flow while the hopper is not empty, slightly raise the lever without seeking to

put it in the top position.

-For faster emptying, levers (5) can be used.

-

Set the seed drill to transport position

-

Place a container under the distribution hoses.

-

Pull levers (5)

-

Take care to lock those levers with the pins after use.

30

Summary of Contents for Tandem Uni-Drill DP400A

Page 9: ...Safety Regulations Safety Stickers 9 ...

Page 17: ...Start Up G TURBINE 17 ...

Page 23: ...Settings A Distribution Settings 23 ...

Page 32: ...Settings H Tramline Track Width 32 ...

Page 41: ...Flow Rate Tables Calibration Procedure 41 ...

Page 42: ...Flow Rate Tables Calibration Procedure 42 ...

Page 43: ...Flow Rate Tables Calibration Procedure 43 ...

Page 44: ...Flow Rate Tables Calibration Procedure 44 ...

Page 45: ...Flow Rate Tables Calibration Procedure 45 ...

Page 48: ...DP400A and DP600A Parts booklet 2002 seeding line ...

Page 52: ...2002 DP600A markers ...

Page 54: ...Marker Circuit Diagram ...

Page 55: ...W Seed box hopper extension ...

Page 56: ...W Seed box Peg Wheels ...

Page 57: ...W Seed box Distributor Assembly ...

Page 58: ...W Seed box Distributor Assembly ...

Page 59: ...W Seed box Variator Assembly W Seed box Variator Assembly ...

Page 60: ...W Seed box half width shut off ...

Page 61: ...W Seed box Venturi System ...

Page 62: ...W Seed box Drive Wheel Assy ...

Page 63: ...W Seed box Wind turbine Assy ...

Page 64: ...W Seed box Air Intake ...

Page 65: ...W Seed box RDS system ...