Maintenance

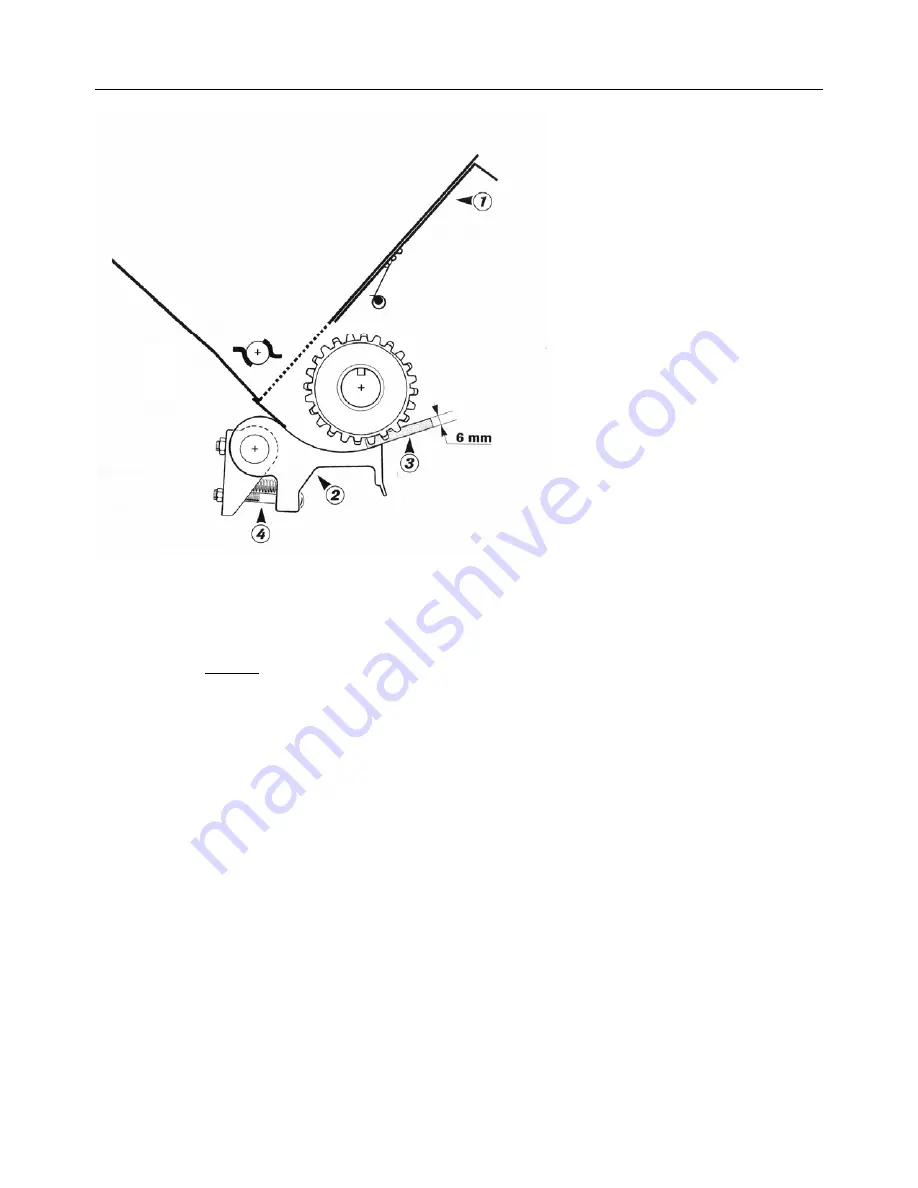

B : Seed Distribution

f)

f)

Metering devices

-

Never leave seed for any length of time in the hopper

-

Open shutters (1) and flaps (2) during the storage period

-

Never lubricate or grease metering devices and seed pips

-

Checks – Incorrect setting of flaps (2) may induce oversowing in the course of work.

It is recommended to check and adjust if necessary after each sowing period-

-Set the flap lever to index 1

-Begin with visually assessing the distance between the flap and the peg

wheel

-If necessary, insert a 6mm spacer (3) between the flap and large space peg

wheel.

Adjust the distance with screw (4).

34

Summary of Contents for Tandem Uni-Drill DP400A

Page 9: ...Safety Regulations Safety Stickers 9 ...

Page 17: ...Start Up G TURBINE 17 ...

Page 23: ...Settings A Distribution Settings 23 ...

Page 32: ...Settings H Tramline Track Width 32 ...

Page 41: ...Flow Rate Tables Calibration Procedure 41 ...

Page 42: ...Flow Rate Tables Calibration Procedure 42 ...

Page 43: ...Flow Rate Tables Calibration Procedure 43 ...

Page 44: ...Flow Rate Tables Calibration Procedure 44 ...

Page 45: ...Flow Rate Tables Calibration Procedure 45 ...

Page 48: ...DP400A and DP600A Parts booklet 2002 seeding line ...

Page 52: ...2002 DP600A markers ...

Page 54: ...Marker Circuit Diagram ...

Page 55: ...W Seed box hopper extension ...

Page 56: ...W Seed box Peg Wheels ...

Page 57: ...W Seed box Distributor Assembly ...

Page 58: ...W Seed box Distributor Assembly ...

Page 59: ...W Seed box Variator Assembly W Seed box Variator Assembly ...

Page 60: ...W Seed box half width shut off ...

Page 61: ...W Seed box Venturi System ...

Page 62: ...W Seed box Drive Wheel Assy ...

Page 63: ...W Seed box Wind turbine Assy ...

Page 64: ...W Seed box Air Intake ...

Page 65: ...W Seed box RDS system ...