24

Settings

SETTINGS

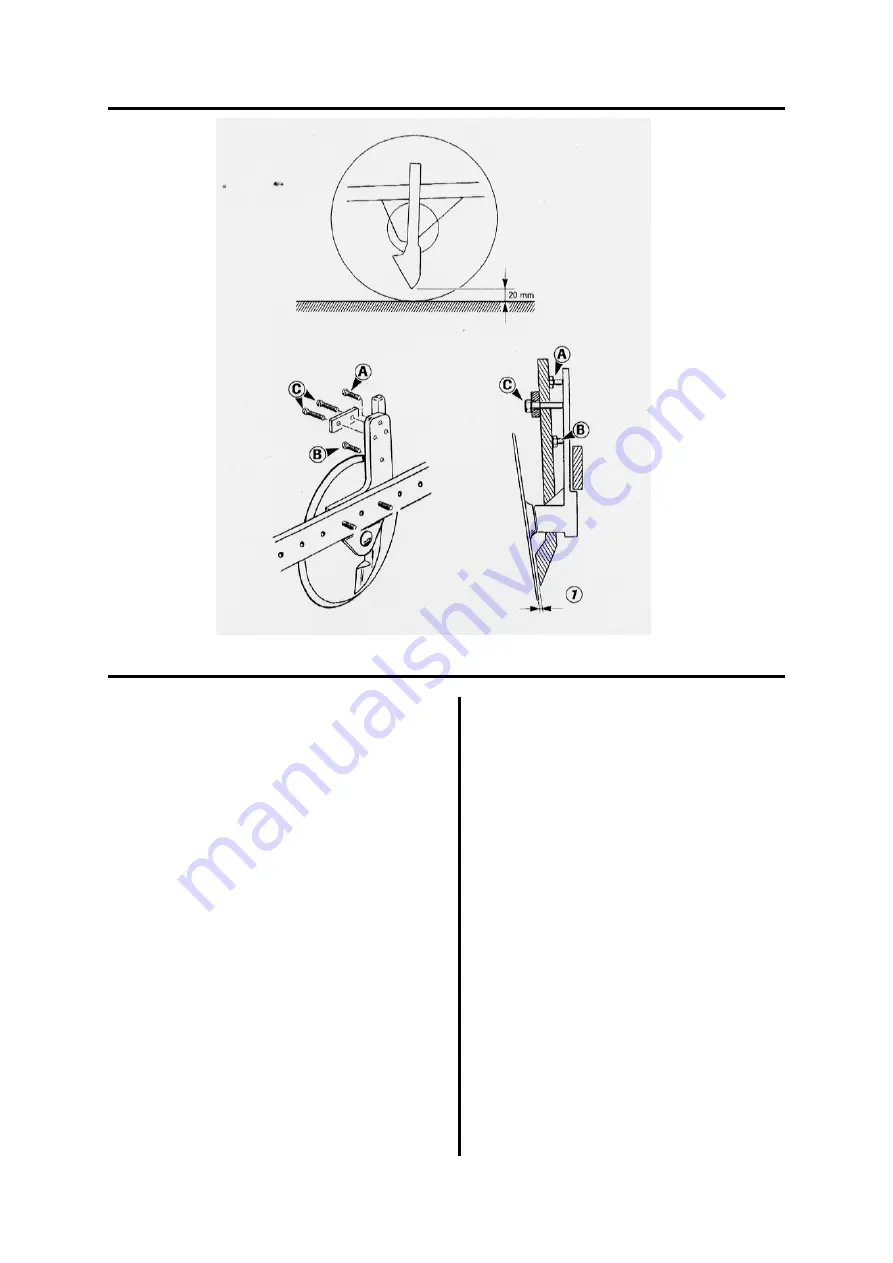

Height setting

The coulter tip must be set approx. 20

mm back from the tip of the disc.

- It is imperative that the minimum

distance is complied with to protect the

coulter from shock damage.

This measurement can be finely adjusted

by placing a wooden block beneath the

coulter with the machine resting on a flat

surface.

NOTE:

When using the seed drill on very

loose or trashy soil it is recommended

that you raise the coulter approx. 40 mm

above the disc to improve its mobility.

Tilt setting adjustment

The coulter’s cutting edge

(1)

must be:

- Parallel to the disc.

- As close to the disc as possible without

limiting it’s rotation.

If the disc does eventually block, the

coulters settings must be adjusted. By

adjusting the tightness of screws

(A)

and

(B),

one can either increase or reduce

the distance between the coulter and the

disc make sure that the coulter’s cutting

edge always remains parallel to the disc.

- Use the screws

(C)

to lock the coulter.

Set the coulters with the machine resting on the ground.

Summary of Contents for UNIDRILL 300

Page 1: ...August 2001...

Page 5: ...4 Safety Regulations...

Page 7: ...6 Warning Symbols 1...

Page 9: ...Safety Instruction Decals 8...

Page 10: ...Safety Instruction Decals 9 25...

Page 29: ...28...

Page 41: ...Maintenance Tyre pressure chart for 10 0 75 15 3 Vredestein Tyres 40...

Page 42: ...Optional Equipment Section 5 MS Flow Modulation 41...

Page 44: ...Starting up 43...

Page 45: ...Starting up 44...

Page 46: ...Operation 45...

Page 47: ...Operation 46...

Page 48: ...Operation 47...

Page 49: ...Operation 48...

Page 50: ...Operation 49...

Page 51: ...50 D E...

Page 55: ...Dragarm Seeding Unit 47 48 54 Parts list...

Page 59: ...Drawbar and Rear Axle Assembly 58 Parts list 47 48 45 1 2 49 3 4 50 51 52 53 53 A B 55 54 35...

Page 61: ...Drive wheel Assembly 60 Parts list 26...

Page 63: ...Seed Box Assembly S900520 S901537 62 Parts list...

Page 65: ...Seed Box Drive Unit 64 Parts list...

Page 67: ...Multiplicator Parts list 66...

Page 69: ...MS Flow Modulation Parts list 1 3 2 7 10 8 9 11 6 5 4 15 14 12 13 68...

Page 71: ...Linak Actuator Tramline Mechanism Parts list 1 5 2 7 6 4 3 9 8 70...

Page 73: ...Seedbox Metering Parts Parts list 10 12 11 8 6 5 4 3 9 2 1 7 72...

Page 75: ...SPI Vertical Lift Marker 74 Parts list...

Page 77: ...Moore Vertical Lift Marker 17 13 16 47 48 Complete disc hub assembly 14 15 74 Parts list...

Page 79: ...Electric Parts Sensors Parts list 1 4 3 2 76...

Page 86: ...Calibration Charts Calibration charts for Rape Barley Peas and Field Beans 83...

Page 87: ...Calibration Charts Calibration charts for Oats Mustard Phacelia and Radish 84...

Page 88: ...Calibration Charts Calibration charts for Lucern Linseed Rye grass and Clover 85...

Page 89: ...Notes 86...