G. DIRECT DRILLING GRASS PASTURES.

Four methods are suggested for direct reseeding grass into grass pastures

.

A.

If the pasture has been badly poached or there are bare patches due to frost kill etc., over

the winter, about 110 Kg/Hectare of a vigorous growing type of grass (e.g. Italian Rye

Grass) should be drilled just before growth starts (March / April).

B.

Where a first cut or second cut of silage is being taken, cut low to the ground and direct

drill the new grass mixture the next day. There should be enough moisture retained in

the soil to germinate the seed and get it growing before the cut sward can fully recover.

C

. Graze the pasture as bare as possible, then spray Gramoxone (1.4 Litres/Hectare) and

direct drill the new seed mixture. The Gramoxone used at a low rate will not kill all the

old grass sward but should retard its growth sufficiently to get the new seeds established.

D. Where the old pasture is very weedy and a complete reseed is required, spray with

Roundup to get a total kill of vegetation. Leave the field for the recommended period

and direct drill with the new seed mixture. To get a better grass cover, cross drilling at

an angle (30 - 45 degrees is recommended, especially with the wider row spacing

UNIDRILLS. Check the reseeds for Leather Jacket, slug or fruit fly damage and treat

accordingly. Grass sown after 1st August should be sprayed with pre-emergence with

Dursban or Spannit to protect from fruit fly and leather jackets. Slug pellets should be

used as required.

H. PREVENTING SOIL COMPACTION

1.

Whenever possible, use low-pressure tyres on all machines operated in fields in

order to reduce superficial compaction

Mounting wide tyres or dual wheels is not enough, the tyre pressure must be adjusted

accordingly. Aim for 0.6 Bar, according to the tyre manufacturer’s recommendations. As the

UNIDRILL is a towed seed drill, it exerts no weight on the rear tractor wheels and does not

require counterweights to be mounted at the front.

2.

Reduce the load per axle to avoid in-depth soil compaction.

Avoid loads over 6 tons per axle, if heavier trailers must be used, park them at the field

entrance. Prefer lightweight trailers, as the UNIDRILL requires little tractor power,

moderately powerful - and therefore light weight - tractors are sufficient.

3.

Till on dried-out ground.

Be patient and wait for the right time of year before starting tillage. According to scientists

as soon as drying soil changes colour, it acquires resistance to compaction. After 4 or 5

years of conservation tillage, the ground drains water faster and becomes more resilient,

which reduces the necessary waiting time. More humus in the soil increases its ability to

carry weight without compacting

4.

Provide calcium and magnesium to compensate the grounds eventual acidity.

Aim to maintain a PH of 6.5 - 7 to ensure optimal stability of the clay-humus compound.

5.

Enrich the soil with organic matters to preserve it from compaction and to

increase its resilience.

Leave straw and culture residues on the ground, spread manure, grow fodder plants and

avoid power harrowing.

33

Operation

Summary of Contents for UNIDRILL 300

Page 1: ...August 2001...

Page 5: ...4 Safety Regulations...

Page 7: ...6 Warning Symbols 1...

Page 9: ...Safety Instruction Decals 8...

Page 10: ...Safety Instruction Decals 9 25...

Page 29: ...28...

Page 41: ...Maintenance Tyre pressure chart for 10 0 75 15 3 Vredestein Tyres 40...

Page 42: ...Optional Equipment Section 5 MS Flow Modulation 41...

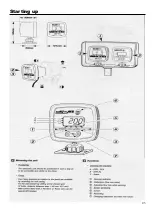

Page 44: ...Starting up 43...

Page 45: ...Starting up 44...

Page 46: ...Operation 45...

Page 47: ...Operation 46...

Page 48: ...Operation 47...

Page 49: ...Operation 48...

Page 50: ...Operation 49...

Page 51: ...50 D E...

Page 55: ...Dragarm Seeding Unit 47 48 54 Parts list...

Page 59: ...Drawbar and Rear Axle Assembly 58 Parts list 47 48 45 1 2 49 3 4 50 51 52 53 53 A B 55 54 35...

Page 61: ...Drive wheel Assembly 60 Parts list 26...

Page 63: ...Seed Box Assembly S900520 S901537 62 Parts list...

Page 65: ...Seed Box Drive Unit 64 Parts list...

Page 67: ...Multiplicator Parts list 66...

Page 69: ...MS Flow Modulation Parts list 1 3 2 7 10 8 9 11 6 5 4 15 14 12 13 68...

Page 71: ...Linak Actuator Tramline Mechanism Parts list 1 5 2 7 6 4 3 9 8 70...

Page 73: ...Seedbox Metering Parts Parts list 10 12 11 8 6 5 4 3 9 2 1 7 72...

Page 75: ...SPI Vertical Lift Marker 74 Parts list...

Page 77: ...Moore Vertical Lift Marker 17 13 16 47 48 Complete disc hub assembly 14 15 74 Parts list...

Page 79: ...Electric Parts Sensors Parts list 1 4 3 2 76...

Page 86: ...Calibration Charts Calibration charts for Rape Barley Peas and Field Beans 83...

Page 87: ...Calibration Charts Calibration charts for Oats Mustard Phacelia and Radish 84...

Page 88: ...Calibration Charts Calibration charts for Lucern Linseed Rye grass and Clover 85...

Page 89: ...Notes 86...