I. BURYING THE STRAW

1.

Select a suitable variety.

According to the selected variety, the quality of produced straw can vary as well as its shock

resistance. A variety that is resistant to illness and does not imperatively require fungicidal

protection at the end of the season will also be more easily decomposed by the fauna in the

soil. A late Spray of Round up is recommended.

2.

Prepare and adjust settings on the combine harvester

Tightening the thresher and increasing the rotational speed will help to break the straw and

help to spread it better. Dry straw breaks more easily under these conditions, harvest the

fields that you wish to sow first. The combine harvester must be imperatively equipped with

a chaff spreader. Shred the straw into chaff of 5-6cm (sharpen the shredder blades, tighten

all belts) and spread evenly. Don’t drill into poorly spread chaff.

3.

Shred the chaff and stubble behind the combine harvester

In particular, if the catch-crop period is short, the cutting level is high, the chaff is poorly

spread out and you wish to till the soil with tools fitted with tines.

4.

As soon as the sowing is finished, keep clean and strong crops growing together.

Use clean seeds that are free of weeds and have a high germinal power. The seeds must be

placed to obtain a fast and even growth, to create a culture that will be able to compete with

weeds and have a high germinal power.

5.

Use a seed drill which causes little disturbance of the soil such as the

UNIDRILL.

The UNIDRILL works exclusively in the sowing line, which avoids seeds that escaped the

stale seed bed from emerging. Prefer wide spacing between rows such as that of the

UNIDRILL (16.6 cm).

6.

Watch for the evolution of the flora during the cultures’ growth period

With conservation tillage, the usual weeds do not appear in the same quantities or at the

same dates: additionally, new species may appear. Prepare for this evolution by improving

your botanical knowledge. Every week while the crops are growing, walk through the fields

moving into plots of land in a continuous series of “Ws”, identifying plants and their

respective development, write any observations down and trace the history of each plot of

land.

7. Use herbicides of new chemical categories every year

Using different Chemicals each year will help avoid crops becoming resistant to the

chemicals.

8.

Clean borders, fallows and crops before the heading

Cut or shred weeds on embankments, in ditches and in fallows rather than treating them

with total herbicide, some perennial plants might not react to the product and may then

become difficult to get rid of. Some find it preferable to grow rye-grass on boarders. It

chokes weeds and can be easily kept under control using a mower. During the season

destroy the remaining localised weed growth spots using localised treatments, using a

strimmer or by hand.

9.

Avoid scattering weed seeds when harvesting

.

Start harvesting the cleanest plots of land. In weed-infested plots, harvest the cleanest parts

first. Clean the combine harvester well after harvesting weed-infested land.

Ploughing is a last resort if the above techniques are not sufficient enough to get rid of

annual grass or dicotyledons.

34

Summary of Contents for UNIDRILL 300

Page 1: ...August 2001...

Page 5: ...4 Safety Regulations...

Page 7: ...6 Warning Symbols 1...

Page 9: ...Safety Instruction Decals 8...

Page 10: ...Safety Instruction Decals 9 25...

Page 29: ...28...

Page 41: ...Maintenance Tyre pressure chart for 10 0 75 15 3 Vredestein Tyres 40...

Page 42: ...Optional Equipment Section 5 MS Flow Modulation 41...

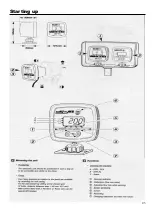

Page 44: ...Starting up 43...

Page 45: ...Starting up 44...

Page 46: ...Operation 45...

Page 47: ...Operation 46...

Page 48: ...Operation 47...

Page 49: ...Operation 48...

Page 50: ...Operation 49...

Page 51: ...50 D E...

Page 55: ...Dragarm Seeding Unit 47 48 54 Parts list...

Page 59: ...Drawbar and Rear Axle Assembly 58 Parts list 47 48 45 1 2 49 3 4 50 51 52 53 53 A B 55 54 35...

Page 61: ...Drive wheel Assembly 60 Parts list 26...

Page 63: ...Seed Box Assembly S900520 S901537 62 Parts list...

Page 65: ...Seed Box Drive Unit 64 Parts list...

Page 67: ...Multiplicator Parts list 66...

Page 69: ...MS Flow Modulation Parts list 1 3 2 7 10 8 9 11 6 5 4 15 14 12 13 68...

Page 71: ...Linak Actuator Tramline Mechanism Parts list 1 5 2 7 6 4 3 9 8 70...

Page 73: ...Seedbox Metering Parts Parts list 10 12 11 8 6 5 4 3 9 2 1 7 72...

Page 75: ...SPI Vertical Lift Marker 74 Parts list...

Page 77: ...Moore Vertical Lift Marker 17 13 16 47 48 Complete disc hub assembly 14 15 74 Parts list...

Page 79: ...Electric Parts Sensors Parts list 1 4 3 2 76...

Page 86: ...Calibration Charts Calibration charts for Rape Barley Peas and Field Beans 83...

Page 87: ...Calibration Charts Calibration charts for Oats Mustard Phacelia and Radish 84...

Page 88: ...Calibration Charts Calibration charts for Lucern Linseed Rye grass and Clover 85...

Page 89: ...Notes 86...