80

MB 200

rev.0.1UL ID1460

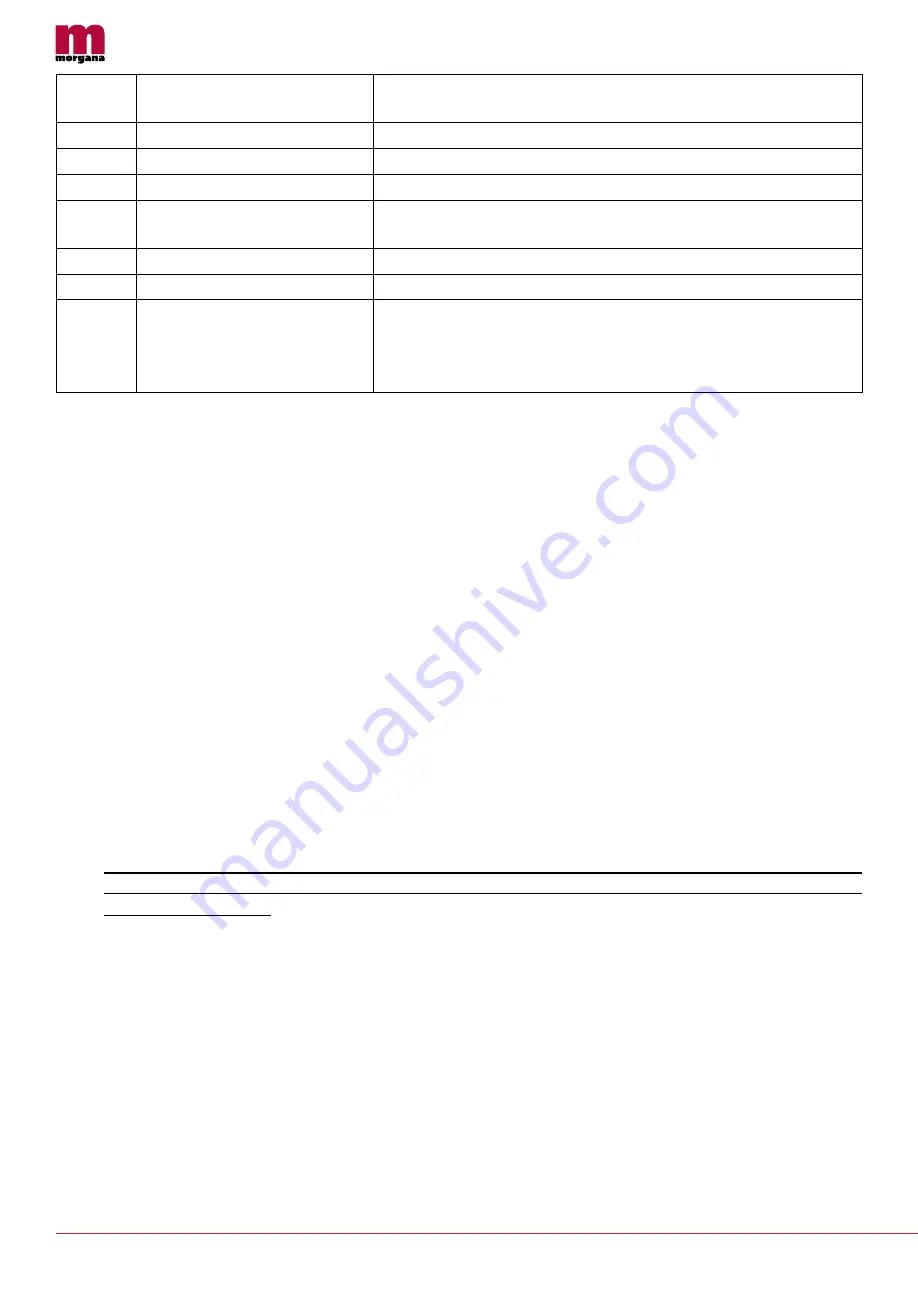

21

Lack of Air

Make sure the input pressure gauge is calibrated to 6 Bar

or that the compressor is the right size.

22

Cover Missing

The cover is not in position

23

Missing manual

The book is not in position

24

Blocked glue photocell

Wipe the stop glue photocell and its reflector.

25

Glue photocell anomaly

The photocell has detected two or more pulses.

Do not insert two books or clean the clamp.

26

Book too thick detected

33

Wait ... Heating

34

Machine with Cleaner

When the machine is switched off the head is cleaned

using the automatic cycle of the cleaner.Use the load cycle

to load the glue.

The cart does not work with this alarm.

ShAVINGS EXTRACTOR - VACUUMS LITTLE:

▪

Make sure that the shavings extractor bin is empty.

▪

Check that the inspection Plexiglas, located on the cutter is free.

▪

Make sure the vacuum hose is not full of shavings.

▪

Check that the suction filter is clean.

▪

Make sure the hose is connected..

VISE - DOES NOT START:

▪

Make sure that the emergency button is disabled.

▪

Check that all doors are closed.

▪

Check the air pressure of the machine.

▪

Check that the cart is in place

▪

Is the display on the main page?

IRREGULAR GLUE START STOP:

▪

Clean the glue application group.

▪

Verify that the temperature of the glue unit is consonant with that of the used glue.

▪

Check the state of the glue. The glue must not be inserted in the machine for too long or kept

at the working temperature. This increases the viscosity of the adhesive itself.

UNEVEN MILL - CUT AND RIBBING:

▪

Make sure that the teeth and notching cutter parts are not cracked or damaged. This may be caused

by books already bound with glue. IF WE NOTICE THAT BOOKS WITH GLUE WERE MILLED, THE

WARRANTY IS VOID.

PLATE GUARD CUTTER - DOES NOT OPEN OR CLOSE CORRECTLY:

▪

Thoroughly clean the contact surfaces of the guard.

hEAD - EXIT OF TOO MUCh OR TOO LITTLE GLUE:

▪

Check the air pressure of the glue unit.

▪

Make sure that the shutter of the head is free, passing the blade provided with the kit.

▪

Check that the lateral sizing holes are free, passing the steel wire supplied with the kit.

▪

Check that the injectors are working properly (must move back and forth with a 8-9 mm stroke).