Page 12

HAND FED CREASING

Running the machine

5. To run the job with the selected settings.

(iii) When the sheets have been fed into the machine and creased; move the

selection switch up, to select

, and then press the System Switch

Stop Feeding

up to stop the machine.

(i) Press the System Switch down, the display will momentarily read

Please Wait

Initiating

High Speed

Low Speed

and then return to show

or

.

Reading stored programs

Any of the nine stored programs can be accessed and read as follows:-

(i) From the start up menu, move the selection switch to the right to select

.

Setup

(ii) Move the selection switch to the right, one click at a time, until the display contains

the word

.

Program

(iii) Move the selection switch down to select,

.

Select Retrieve Settings

( v) Move the selection switch to the right to select,

.

Ok

i

(v) Move the selection switch to the right or to the left to select,

to

.

Program 1

Program 9

(vi) Move the selection switch up to select,

.

Load

(vii) Move the selection switch up again to select,

.

Ok

The details of the selected program can now be viewed or edited.

Paper jamming

In the event of a paper jam occurring whilst the machine is operating the display will

read

Paper Jam.

In order to remove the paper causing the jam, move the selection switch

to the left or to the right to drive the paper forwards or backwards in short pulses.

Setting the Speed (High Speed or Low Speed)

4. (i) Move the selection switch to the right to select

.

Setup

(ii) Move the selection switch to the right again to select

.

More

(iii) Move the selection switch up or down to select

or

.

High Speed

Low Speed

(iv) Move the selection switch to the right to select

.

Ok

(ii) Move the selection switch down to select

, and feed the sheets individually

Feed

into the rollers.

(v) Move the selection switch up, step by step, until the display contains the

word

.

Feed

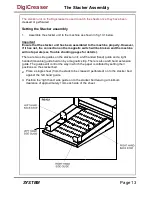

Operating the Digicreaser