Page 47

Trouble Shooting

SYSTEM

l

l

l

l

Check that the air distribution has been correctly set.

Check that the air separation has been set high enough to feed the sheets.

For heavy stocks, very small or very large sheets, embossed or even irregular stock,

it may be required to feed the sheets manually - see page 20 for instructions.

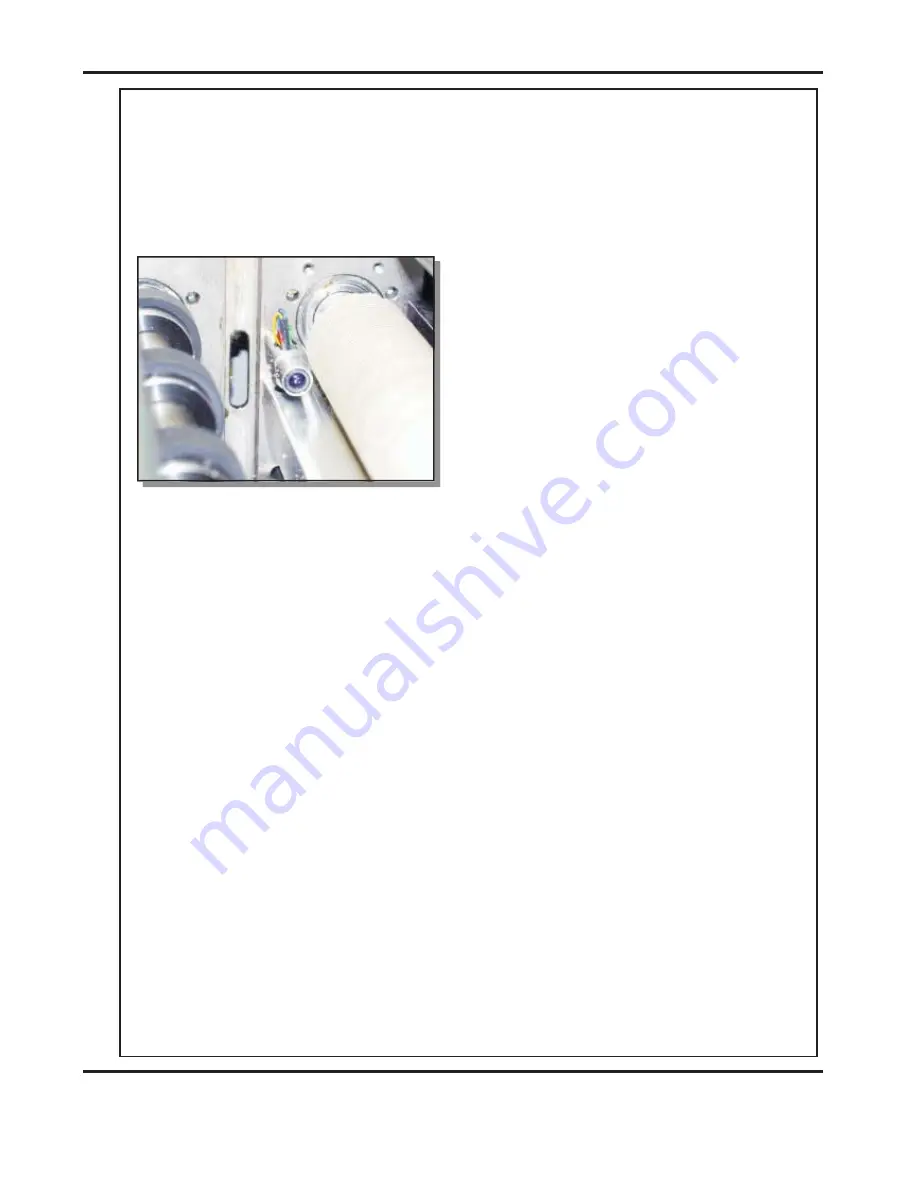

Open the exit and remove the blade set

(see pages 44-45) to access the dual

sensor post located in between the drive

rollers. Using a soft brush, clean the

visible sensor on the end of the post.

Use the brush to clean the sensors

between the post and the bottom paper

guide which are not visible.

Photograph (left) shows the dual sensor

post containing the sensors.

If the suction drum is not rotating, check all of the drive belts for cleanliness and

splits (including the bottom in-feed roller drive belt).

.

If at any time during the creasing process the control panel reads

it

is indicating that the lower blade / anvil has not made contact with the HOME switch ie.

blade still in top position. Switch the machine off and remove the blade set and ensure

that the area is free from obstructions. Return the blade set to the creasing unit

and switch the machine on. Operate the machine in the normal sequence, if the

display continues to read

it is advised to contact a Service Engineer

immediately.

If before operating the machine the display reads

this

indicates that there is an obstruction between the upper sensor assembly and the

paper guide sensor (as shown in the above photograph). If there is no obvious

obstruction in the paper path, switch the machine off and repeat the same procedure as

explained above.

Machine not counting

No suction

Control panel reads

Blade Not Home

The Paper Path is not clear

l

l

Blade Not Home

Blade Not Home

The Paper Path is not clear

DocuMaster MK3