Page 26

CREASING / BOOKLET MAKING

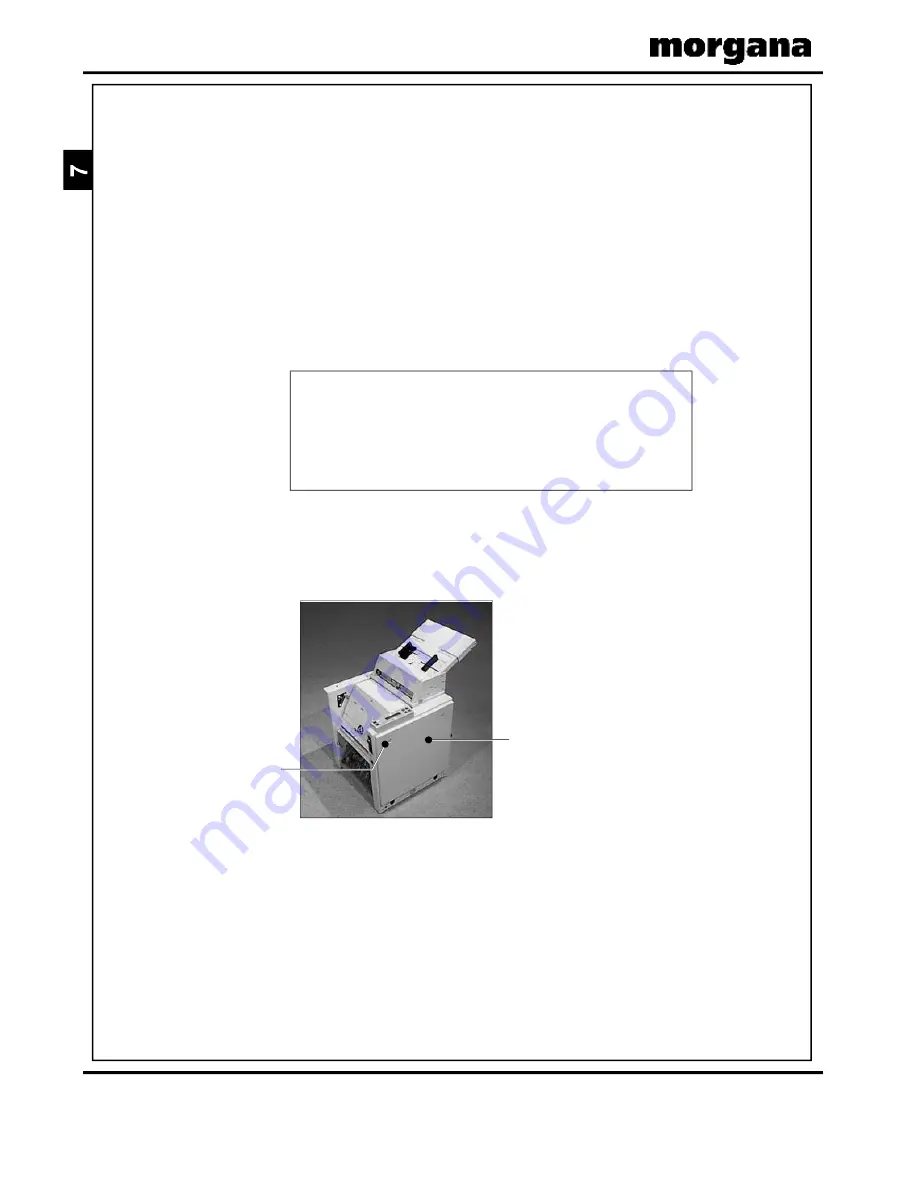

FIGURE 27

M5 Button Screw

Right Hand Side Cover

MAINTENANCE

The BMP and TMP units require only a small amount of

routine maintenance.

CLEANING Build up of set-off powder, ink or general dust will grad-

ually impair the performance of your BMP and TMP.

Optimum performance will be obtained by keeping the

machine clean.

Fold Roller and Conveyors

Build-up of set-off powder or ink on the fold rollers and

conveyor belts will eventually cause slippage or ink

transfer.

Warning!

Access to the manual cranking points on the BMP and

TMP requires the side covers to be removed. For safety

reasons this procedure should therefore only be con-

ducted by authorised personnel. Disconnect the power

before removing the side covers.

BMP

To clean the rollers and belts on the BMP, first remove

the right hand side cover (two x M5 button screws) to give

access to the manual cranking point (see Figure 27).

Open the BMP lid to access the fold rollers. Using a 10mm

A/F spanner (wrench), manually crank the BMP by turning

the nut (see Figure 28) clockwise, and clean the rollers.

Summary of Contents for Documaster Pro

Page 11: ...Page 9 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 15: ...Page 13 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 19: ...Page 17 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 23: ...Page 21 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 27: ...Page 25 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 31: ...Page 29 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 35: ...Page 33 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 45: ...Page 43 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 47: ...Page 45 SYSTEM DocuMaster Pro ...