Page 32

CREASING / BOOKLET MAKING

FIGURE 35

Fold Position Fine Tuning

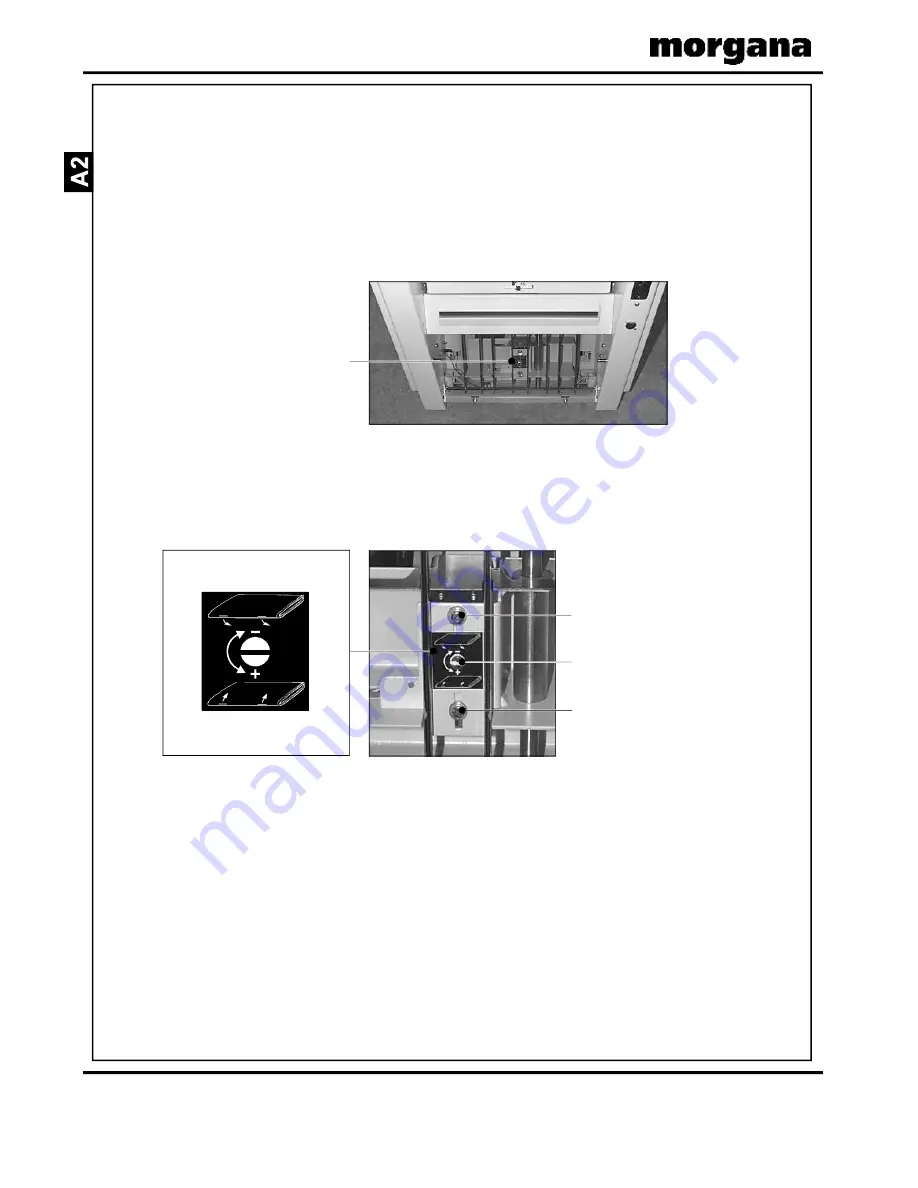

FIGURE 36

Fine Adjustment Screw

Turn Anticlockwise to

Raise the Staples

Turn Clockwise to

Lower the Staples

Locking Screw

Locking Screw

STAPLE POSITION ADJUSTMENT

Tools required

If both staples are consistently off the spine of the book

Flat Blade Screwdriver

first ensure that the BMP is adjusted correctly and that

delivery into the unit is good. If the problem persists, fine

tuning of the staple position may be necessary. Adjust-

ment is via the central screw on the fold plate mechanism,

located behind the perspex cover (see Figure 35).

If necessary, adjust the fold position until the screws align

with the holes in the perspex cover. Using a flat blade

crewdriver, loosen the two locking screws (see Figure

36).

Turn the fine adjustment screw (see Figure 36) clockwise

to lower the position of the staples (as viewed when the

book exits the unit) and anticlockwise to raise the staples.

One quarter turn of the screw equates to approximately

2mm of travel.

Tighten the locking screws and produce a test booklet.

Repeat the procedure if necessary.

Summary of Contents for Documaster Pro

Page 11: ...Page 9 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 15: ...Page 13 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 19: ...Page 17 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 23: ...Page 21 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 27: ...Page 25 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 31: ...Page 29 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 35: ...Page 33 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 45: ...Page 43 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 47: ...Page 45 SYSTEM DocuMaster Pro ...