Page 34

CREASING / BOOKLET MAKING

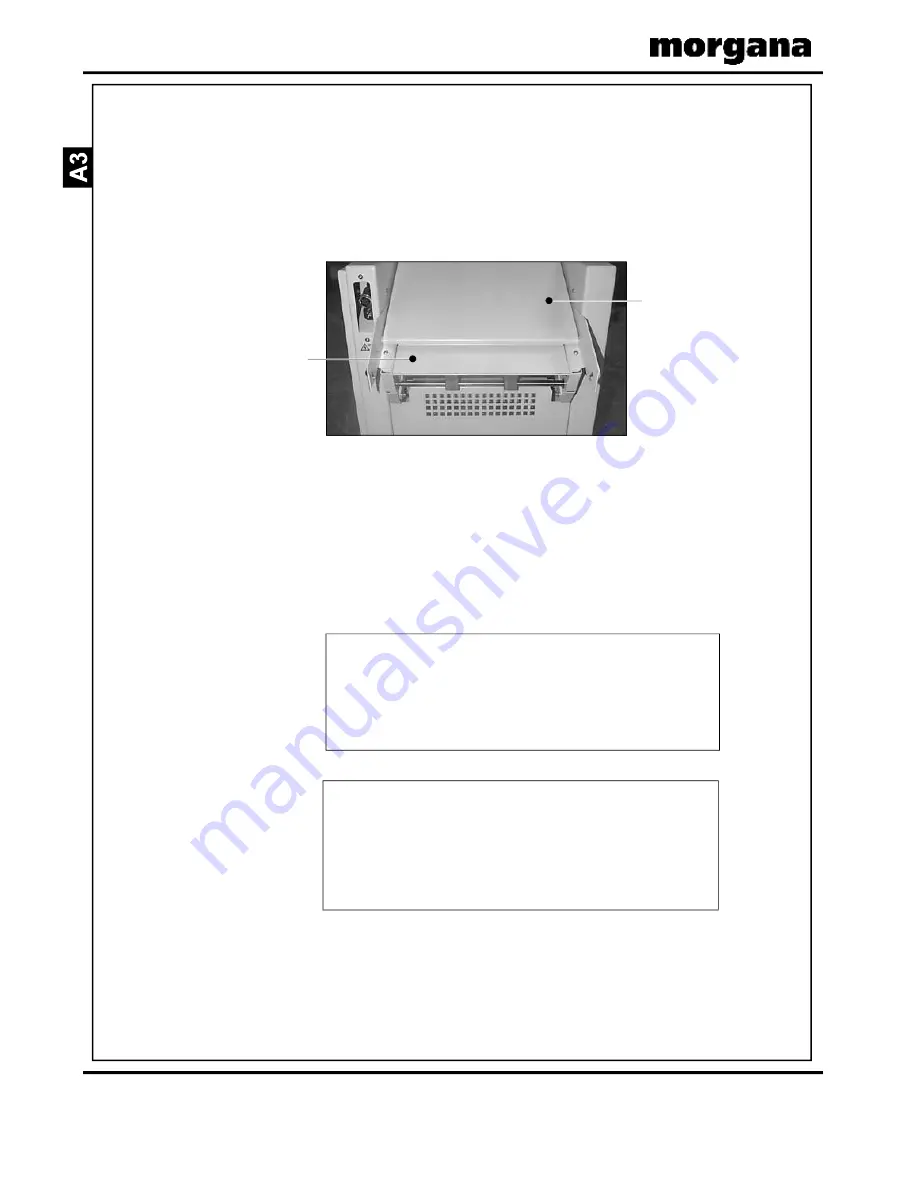

FIGURE 37

Conveyor Assembly

Conveyor

Cover

SHARPENING THE TMP BLADE

The TMP blade and anvil are located behind the conveyor

assembly (see Figure 37) at the docking end of the unit.

Periodically all TMP blades will require re-grinding. Poor

grinding will result in poor life, and can cause cracks and

nicks in the blade. We therefore offer the guidelines on

page 39 which should accompany the blade and anvil

when they are sent for regrinding. Whenever the TMP

blade is reground, check the condition of the anvil also.

This will only require regrinding if it has become dam-

aged.

Warning!

This procedure is potentially hazardous and should only

be conducted by suitably skilled personnel. Disconnect

the power before removing the conveyor assembly.

Handle the blade with extreme caution and keep hands

clear of cutting edges at all times.

Parts Required (if necessary)

Tools Required

TMP/1189 onwards:

3mm allen key

253-835 TrimMaster blade & guide

4mm allen key

TMP/1188 and earlier:

6mm allen key

253-173 TrimMaster blade

10mm allen key

19mm spanner

.

Summary of Contents for Documaster Pro

Page 11: ...Page 9 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 15: ...Page 13 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 19: ...Page 17 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 23: ...Page 21 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 27: ...Page 25 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 31: ...Page 29 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 35: ...Page 33 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 45: ...Page 43 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 47: ...Page 45 SYSTEM DocuMaster Pro ...