Page 39

SYSTEM

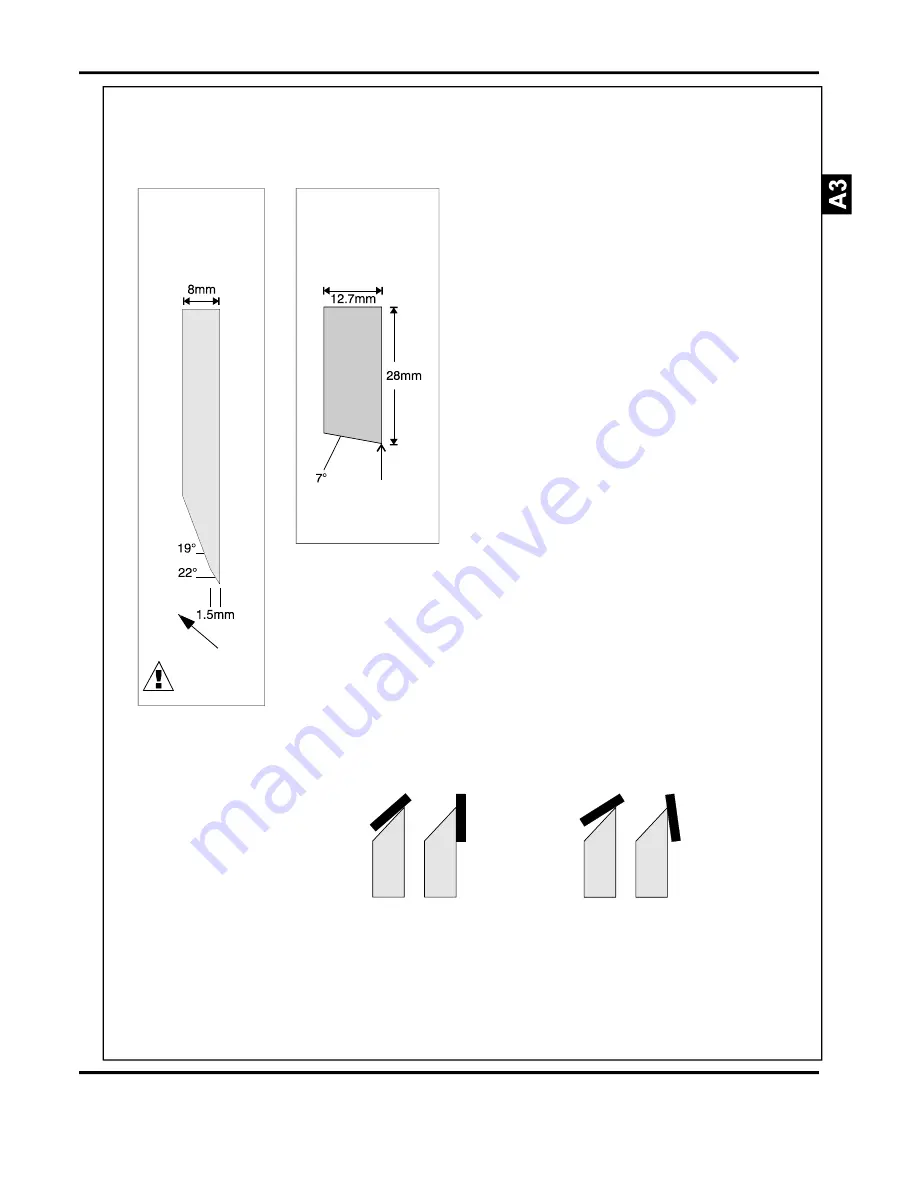

Note:

2 faces must

be flat to within

0.03mm

Important:

Grind In This

Direction Only

BLADE

Note.

2 faces must

be flat to within

0.01mm

This edge must

be straight to

within 0.04mm

ANVIL

Correct

Incorrect

TrimMaster Blade Grinding Instructions

TrimMaster blade 253-835 is fitted with a

guide leg. This

be removed when the

blade is reground and refitted afterwards.

Blade Material High Carbon High

Chrome (Aisi D2/D3)

Grinding Angle See drawing alongside

Grinding Wheel Cup or Cylinder

Grinding Material Grit : 46-60

Hardness : G-H

Bond : Vitrified

Peripheral speed 20-26 (V M/S)

of the grinding wheel 65-85 (V Ft/S)

Table Speed 20-26 (V M/Min)

65-85 (V Ft/Min)

Feed per pass 0.01 - 0.02mm

0.0004 - 0.0008"

Honing

After re-grinding, the burr should be carefully removed

by honing. The quality of honing affects the useful life of

the cutting edge.

Note:

must

DocuMaster Pro

Summary of Contents for Documaster Pro

Page 11: ...Page 9 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 15: ...Page 13 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 19: ...Page 17 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 23: ...Page 21 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 27: ...Page 25 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 31: ...Page 29 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 35: ...Page 33 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 45: ...Page 43 SYSTEM THIS PAGE IS INTENTIONALLY BLANK DocuMaster Pro ...

Page 47: ...Page 45 SYSTEM DocuMaster Pro ...