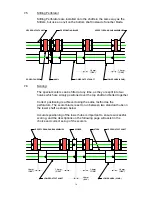

The sensor lenses and the underside of the reflector should be dusted

regularly, especially if set-off spray powder is used on the stock.

A thorough cleaning of the sensor lenses is best achieved by raising the feed

bed and then using a soft brush to clear away all dust.

11.2

Regular Maintenance

The UFO Folding Machine has been designed for minimum maintenance;

however, the following items will need attention.

Weekly

-

The two roller shafts on the feed bed should be cleaned and

sparingly oiled (see page 37, items 50 and 60 of the spare parts

manual).

The counter sensor lenses and reflector must be dusted

regularly to ensure reliable counter operation (see page 25 of

this book).

This will also affect the feed if dirty.

Monthly

-

The air filter, mounted on the compressor, must be removed

and cleaned. Access to the compressor is made by loosening

the two screws at the top surface of the base access door (fold

plate end). (See page 25 of the parts manual).

3 monthly - Lubricate the two idler gears on the swinging perforating unit

using a light machine oil.

6 monthly - The drive motors have carbon brushes with an average life of

1000 hours. These brushes should be inspected periodically,

call our Service Department for advice.

(See pages 21 and 35 of the parts manual).

SECTION 12:

FAULTS

Problem

Cause

Machine dead and no

Not switched on.

lights on front panel

Fuse blown in plug or external power supply.

Large connector on rear of control box loose.

Logic fuse blown (see page 20).

Compressor runs but

Feed bed raised.

both motors do not

Guard up.

Crossfold not plugged in.

One of the drive

Check individual motor connections.

motors fails to work

Check individual motor fuse (see page 20).

Check individual motor brushes (contact agent for

advice).

Not counting

Sensor lenses dusty (see page 25).

Machine running in 'stream’.

Connector loose in rear of control box.

26