A-8 DAILY INSPECTION

6.

CLEANING MACHINING CHAMBER/SETUP STATION

To maintain machining accuracy for the optimum length of time, always clean the machining

chamber and setup station daily following completion of machine operations.

Do not use compressed air to clean the machining chamber and setup station.

If compressed air is used inside the machining chamber and setup station, chips and

coolant may enter the spindle tapered section and bearings resulting in serious

damage.

6.1

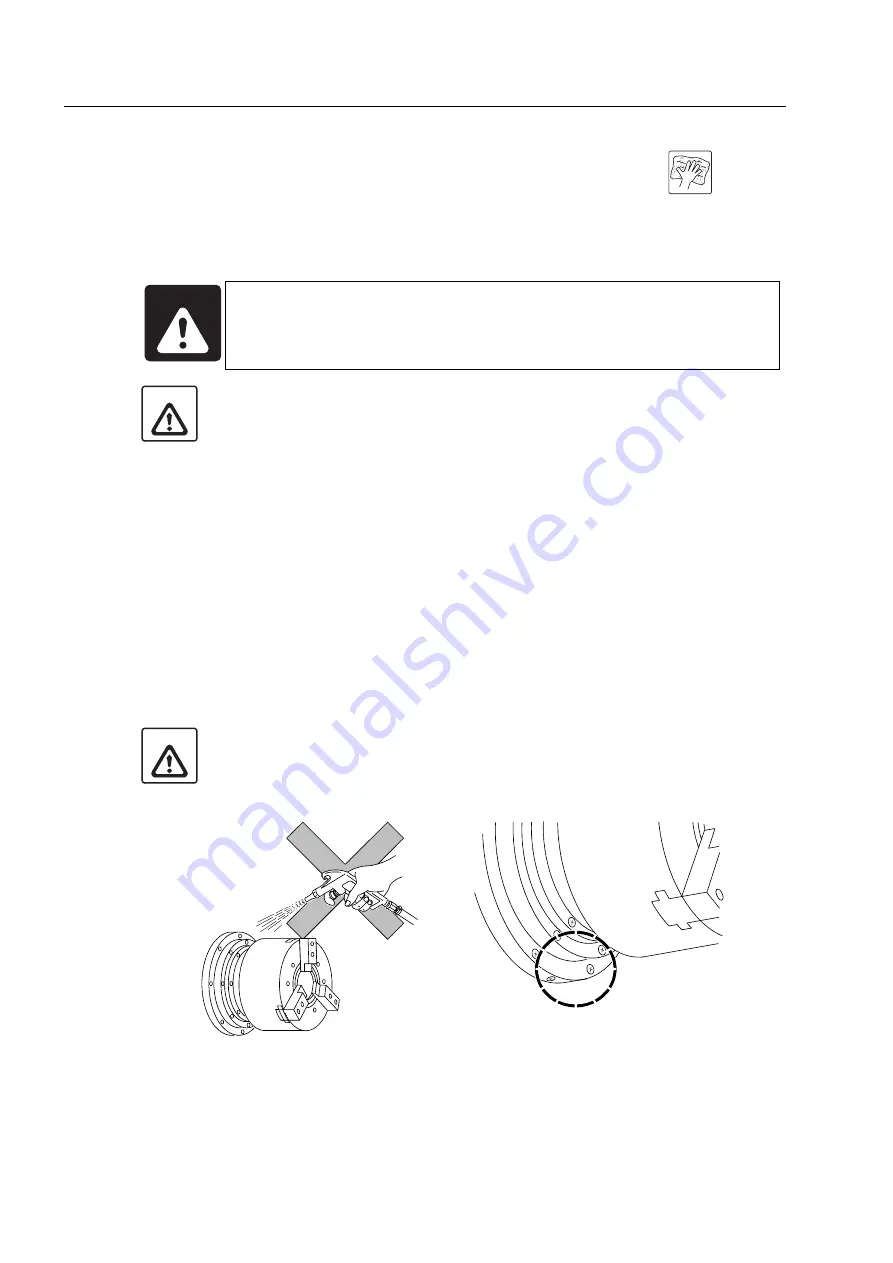

Cleaning the Front Cover of the Spindle

Dust and foreign matter will accumulate in the coolant holes on the front cover of the spindle

allowing coolant to enter the bearings. This will cause the bearings to seize.

Clean the coolant holes in the front cover of the spindle at least once a week.

<Cleaning interval>

Every 50 hours of operation

Do not use compressed air to remove dust and foreign matter from the coolant holes.

If compressed air is used, dust and foreign matter will enter the bearings.

DANGER

When inspecting and cleaning the machining chamber and setup station,

turn OFF the main power and disconnect the plant-side power supply

(breaker).

CAUTION

CAUTION

Coolant discharging hole