B-8 REGULAR INSPECTION

13) Press the manual lubrication button for more than 10

seconds to supply lubricant to the slideways.

14) Make sure that lubricating oil is supplied to the

slideway surfaces.

6.2

Inspection Items for the Lubricating Oil Tank

Periodic inspection items for the lubricating oil tank are indicated below.

By referring to the inspection items, carry out inspection and maintenance work at the specified

inspection intervals.

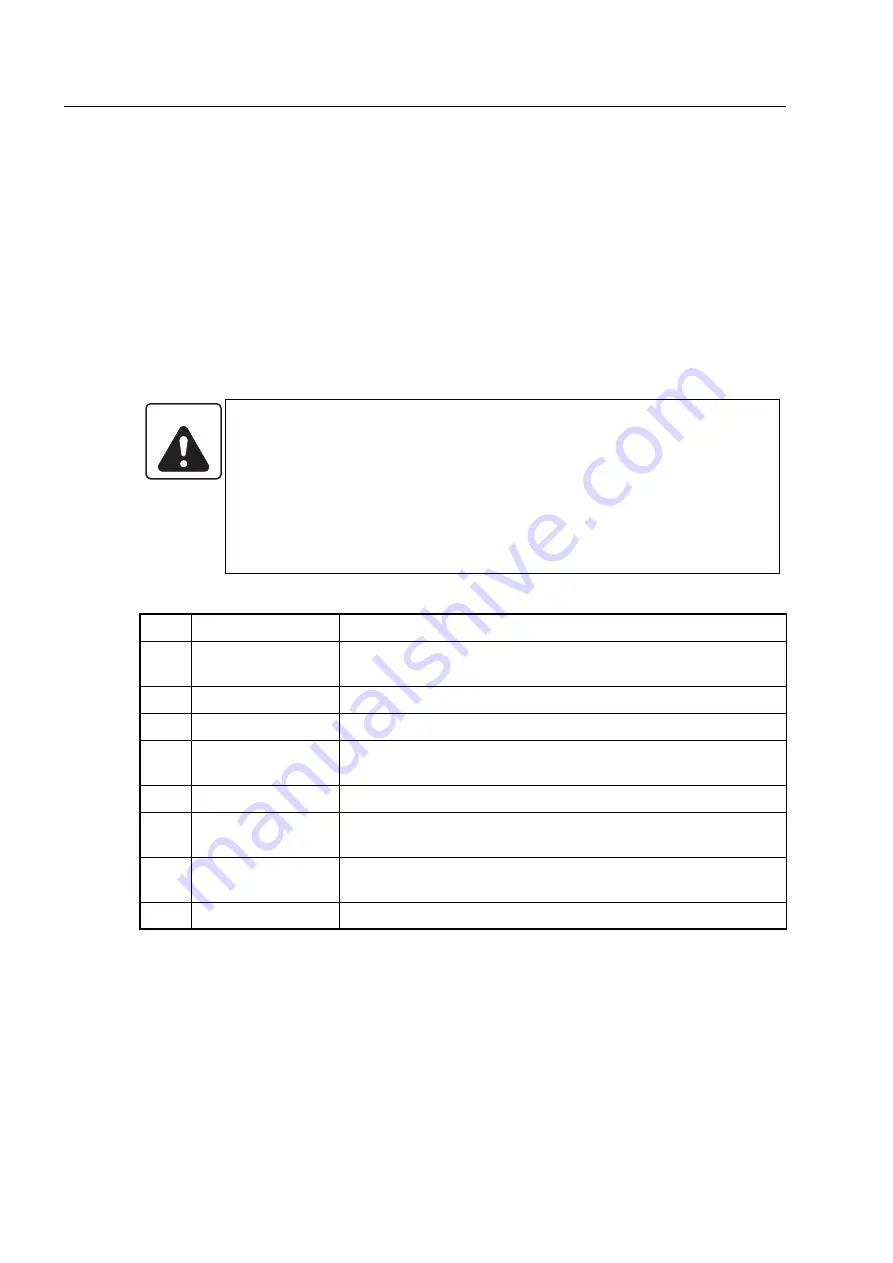

WARNING

(7) Always turn the power OFF before performing inspection and

cleaning the lubricating oil tank. When the power is turned ON, the

internal fan starts to rotate. If the fan is rotating during the cleaning

procedure, hands or clothing may become entangled, resulting in

serious injury.

(8) Use only kerosene for cleaning the lubricating oil tank and the fill port

filter. Do not use volatile fluid such as gasoline or thinner.

No.

Inspection Item

Contents

1

Fill port filter

Check that the fill port filter is properly installed, that the filter is

not damaged and that foreign matter does not adhere to the filter.

2

Oil in the tank

Check for deterioration, oxidation, and dirt.

3

Inside of the tank

Check for chips, foreign matter and sludge.

4

Tightness of piping

connections

Check for oil leakage from all joints.

5

Piping tube

Check the piping tube for damage.

6

Oil consumption in

the tank

Check that oil consumption in the tank is appropriate.

7

Pump

Turn on the lubricating oil pump and check that the lubricant

pressure rises to the setting pressure properly.

8

Distributor

Check that oil is supplied from the distributor properly.