141

ʅʩʓʳɮᚽᏚᴥɴʡʁʱʽᴦ

SEMI DRY-CUT SYSTEM (OPTION)

2

าᜤ

2

NOTE

ᤆᢆ˹ȺɕፈบȬɞȦȻɂȺȠɑȬȟǾፈบ˹ɂบɁΖፈȟඨɑ

ɝɑȬǿᩋȢȰɁৰȟፖȢȻʩʃʒȟҋȽȢȽɝɑȬɁȺǾᤆ

ᢆ˹ȾፈบȬɞکնɂਖ਼ȢጶɢɜȮȹȢȳȨȗǿ

Oil replenishment is possible even while the machine is operating.

But oil supply will stop during replenishment, and if the oil supply

stops for a long period, the mist will also stop. So finish

replenishment quickly if it is being done while the machine is

operating.

2)

ፈบՠɷʭʍʡɥɝ۶Ȭǿ

2)

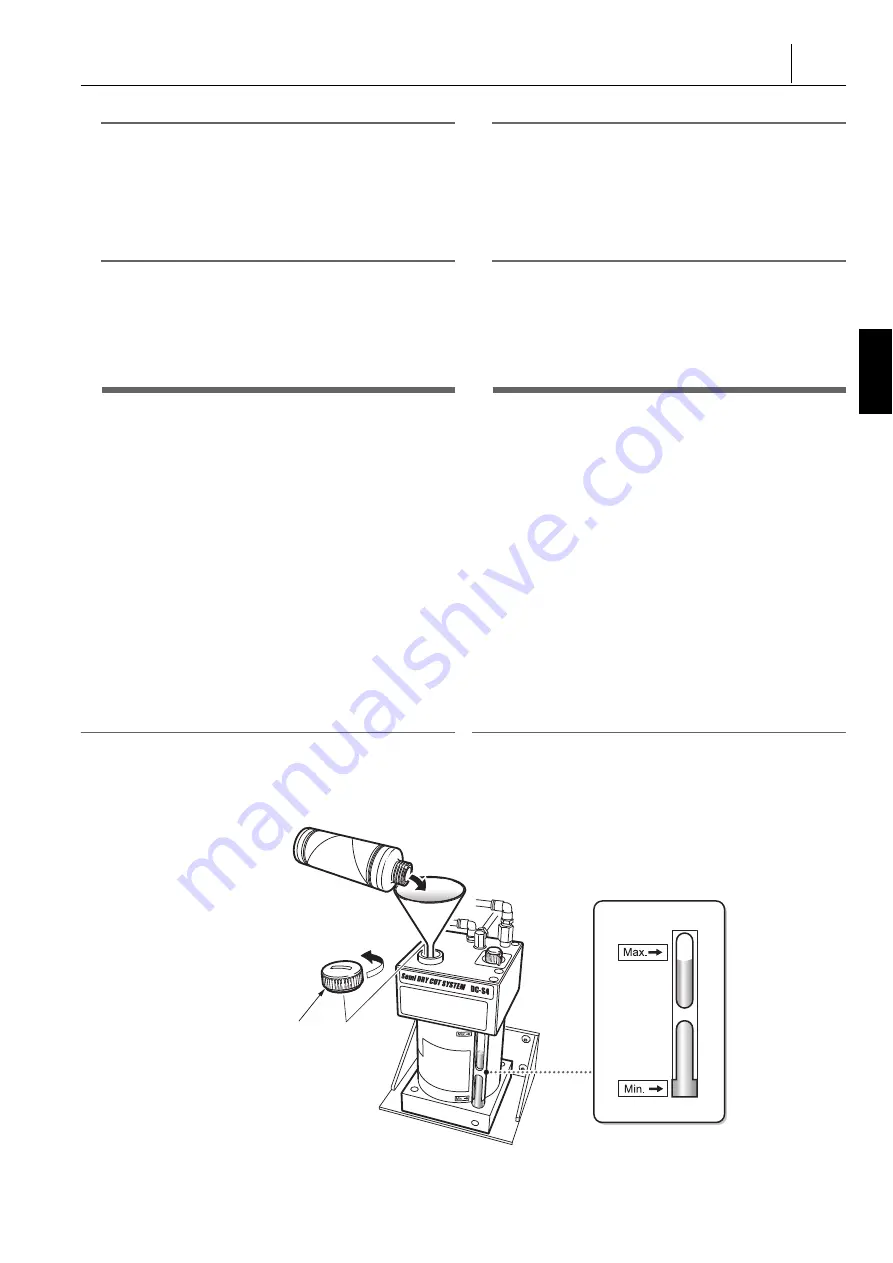

Remove the fill port cap.

2

าᜤ

2

NOTE

ፈบՠɷʭʍʡɥɔɞȻю٢ȟᜓȨɟɑȬǿ

The internal pressure is released when the fill port cap is loosened.

3)

ްบ

“

ɬʵʐɭʨ

”

࿎ॴʩʃʒႊ༁໙บᴥႎ˹ɮʽ

ʧ˂ʒɺʵ˂ʡᛏᴦɁоȶȲʦʒʵȺፈบȬɞǿ

3)

Supply oil from a bottle containing the designated oil,

“ULTIMA” plant-derived lubricant for mist made by TANAKA

IMPORT GROUP.

7

า

7

CAUTION

1.

ްบ

“

ɬʵʐɭʨ

”

࿎ॴʩʃʒႊ༁໙บɥΈႊȪ

ȹȢȳȨȗǿͅɁบɥΈႊȪȹႆȫɞϧ࣐˨Ɂࣷɗ

ൡبɁૺϾǾཌདȽȼɁૺ܅ȾȷȗȹǾࣷᇋɂˢҒɁ

͖ɥ២ȗɑȮɦǿ

1.

Use genuine “ULTIMA” plant-derived lubricant for

mist. Mori Seiki cannot accept any responsibility for

trouble or problems such as fire, health problems,

or machine damage caused by using an

unauthorized oil.

2.

٥ڒȾɛȶȹްบɥоਖ਼ȺȠȽȗکնɂǾ͏˩Ɂᄾ

छบɥΈႊȪȹȢȳȨȗǿ

2.

The designated oil may not be available in some

areas. In that case, use the following equivalent

products.

ɵʃʒʷ˂ʵ

ɻɬ˂ɵʍʒ

ES1

Castrol CareCut ES1

ɵʃʒʷ˂ʵ

ɻɬ˂ɵʍʒ

ES2

Castrol CareCut ES2

3.

Έႊ˹ɁบȻႱȽɞͅʫ˂ɵ˂ɁบɥຉնȪȹΈႊȪ

ȽȗȺȢȳȨȗǿͅʫ˂ɵ˂ɁบɥΈႊȬɞکնɂǾ

ʉʽɹюȾරȶȹȗɞบɥީпȾȗȹǾʉʽɹюɥ

ຏોȪȹȞɜΈႊȪȹȢȳȨȗǿͅʫ˂ɵ˂Ɂบɥຉ

նȪȲɝǾްบ͏۶ɁบɥΈႊȪȹႆȫȲൡಽɁ

᪩ȾȷȗȹǾࣷᇋɂˢҒɁ͖ɥ២ȗɑȮɦǿ

3.

Do not mix in an oil different from the oil in current

use. When changing to a different brand of oil, drain

all the original oil from the tank completely, clean

the inside of the tank, and then add the replacement

oil. Mori Seiki is not responsible for problems

arising from the mixing of different brands of oil or

the use of non-specified oils.

2

าᜤ

2

NOTE

ʉʽɹ߁ᦀɂ

1000 cc

ȺȬǿɴɮʵʶʣʵɼ˂ʂɁ˨᪅ɥᠰțȽȗɛ

șȾፈบȪȹȢȳȨȗǿ˨᪅ɥᠰțɞȻǾю٢ȟ˨ȟɜȭʩʃʒȟढ

ȨɟȽȗکնȟȕɝɑȬǿ

The tank capacity is 1000 cc. Take care not to exceed the upper limit

on the oil level gage. If the oil level exceeds the upper limit, the internal

pressure will not rise and mist will not be formed.

4)

ፈบՠɷʭʍʡɥɝ͇Ȥɞǿ

4)

Remount the fill port cap.

Oil Level Gage

Fill Port Cap

ɴɮʵʶʣʵɼ˂ʂ

ፈบՠɷʭʍʡ

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......