163

ᯚ٢ɹ˂ʳʽʒᚽᏚᴥɴʡʁʱʽᴦ

HIGH PRESSURE COOLANT UNIT (OPTION)

19

ᯚ٢ɹ˂ʳʽʒᚽᏚᴥɴʡʁʱʽᴦ

HIGH PRESSURE COOLANT UNIT (OPTION)

8

ឬ֖

8

WARNING

1.

ᯚ٢ɹ˂ʳʽʒᚽᏚ͇ࠖɁͽᝢంɥᝣɦȺю߁ɥԚґ

ျᜓȬɞɑȺɂǾͽȝɛɆίަཟ೫ɥᚐɢȽȗȺȢȳȨ

ȗǿ

1.

Do not operate the high pressure coolant unit or

perform maintenance and inspections without reading

and obtaining a thorough understanding of the

contents of the operation manual provided with the

high pressure coolant unit.

2.

ᯚ٢ɹ˂ʳʽʒᚽᏚ͇ࠖɁͽᝢంɂǾᯚ٢ɹ˂ʳʽʒ

ᚽᏚɁȰɃȾίከکɥᜫᏚȪǾ۾ҒȾίከȪȹȢȳȨ

ȗǿ

2.

Keep the high pressure coolant unit operation manual

on hand to enable immediate reference.

3.

ίަཟ೫ጶ̘ऻǾൡಽሜӦҰȾȬɌȹɁɵʚ˂ɥЫȼȝɝ

Ⱦɝ͇ȤȹȢȳȨȗǿ

3.

After the completion of the maintenance and

inspections, remount all covers before running the

machine.

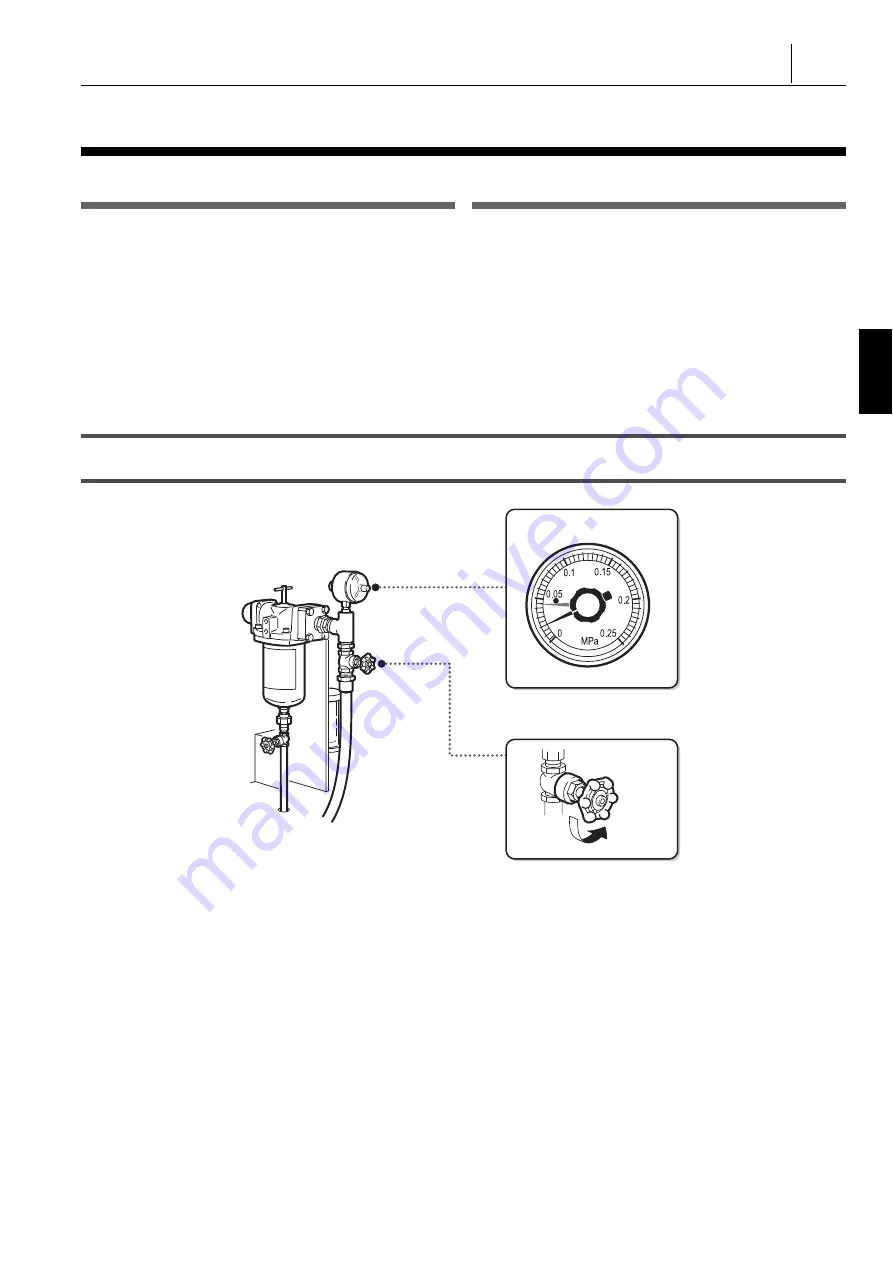

19-1

Ζፈ٢ӌɁཟ೫Ȼᝩ

Suction Pressure Inspection and Adjustment

ᴹਖ਼ᬲᴻ

<Procedure>

1)

˨ȥʧʽʡȟͽӦȪȹȗɞৰȺǾΖፈ٢ӌȟ

0.02

Ⱥ

ȕɞȦȻɥᆬᝓȬɞǿ

1)

Check that the suction pressure gage is set at 0.02 MPa

with the suction pump running.

2)

ᝩȟ॒ᛵȽکնɂǾΖፈ٢ӌɥȽȟɜǾΖፈ٢ӌᝩ

ʚʵʠɥߵȪȭȷوȪȹᝩȬɞǿ

2)

If necessary, slowly rotate the suction pressure regulating

valve while checking the suction pressure gage.

ۄ٢ᴷʚʵʠɥࡿȾوȬǿ

Increasing pressure: Rotate the valve CCW.

ນ٢ᴷʚʵʠɥծȾوȬǿ

Reducing pressure: Rotate the valve CW.

1

ᝊጯɂᯚ٢ɹ˂ʳʽʒᚽᏚ͇ࠖɁͽᝢంɥՎྃȪȹȢ

ȳȨȗǿ

1

For further details, refer to the operation manual provided

with the high pressure coolant unit.

Suction Pressure Regulating Valve

Open

Pressure Gage with Contactor

Ζፈ٢ӌᝩʚʵʠ

ᩒ

ཟ͇٢ӌ

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......