༁໙บʰʕʍʒɁႱࢠ

LUBRICATING UNIT ALARMS

198

8

ឬ֖

8

WARNING

ൡಽໃɥȪɖȪȹȢȳȨȗǿ

Turn OFF the main power.

ᴹਖ਼ᬲᴻ

<Procedure>

1)

࿁ՠʃʛʔɥΈȶȹʴʴ˂ʟʚʵʠɥʧʽʡటͶȞɜɝ

۶Ȭǿ

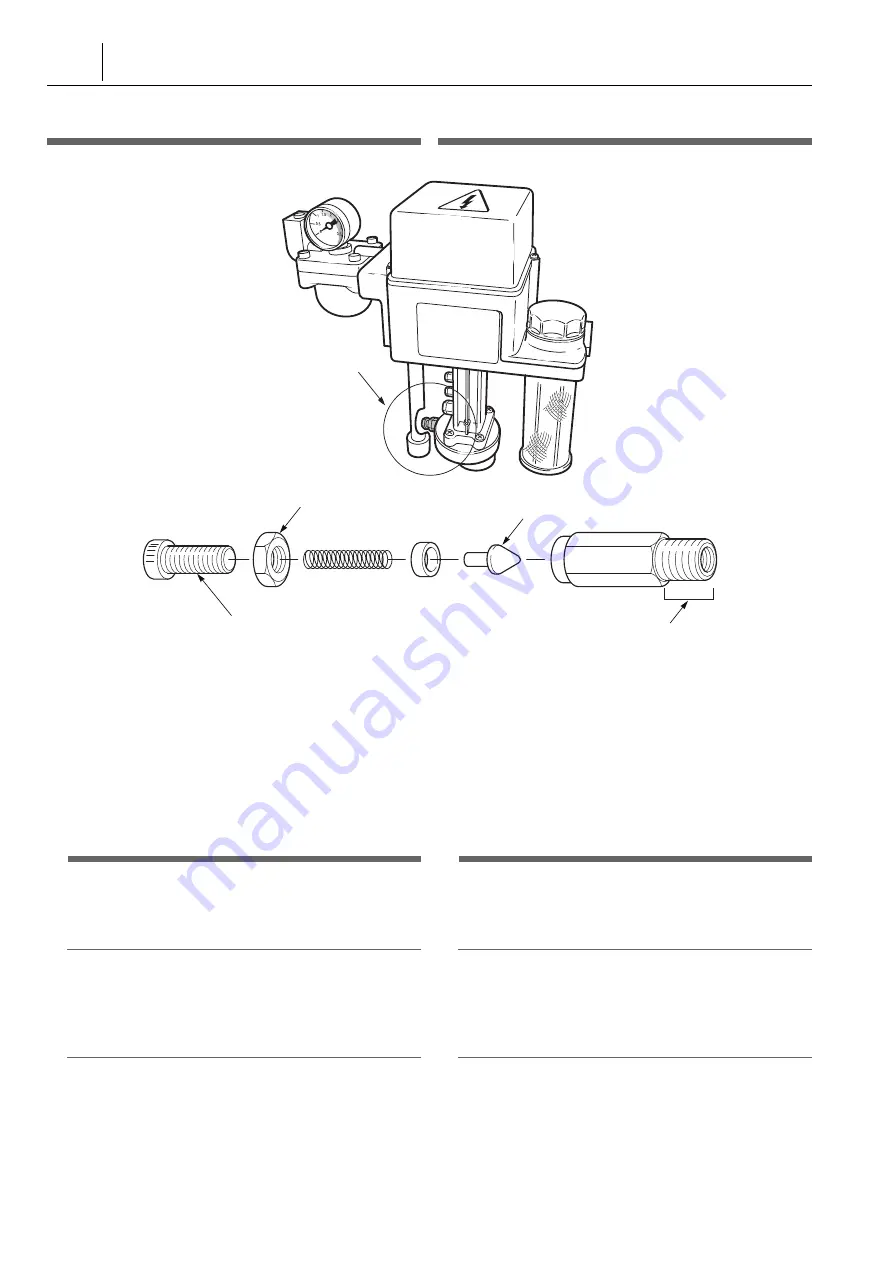

1)

Detach the relief valve from the pump using a single-ended

wrench.

2)

ʷʍɹʔʍʒɥɔȹᝩɀȫɥɝ۶Ȭǿ

2)

Loosen the lock nut and remove the adjusting screw.

3)

ґᜓȪȲʴʴ˂ʟʚʵʠɥɲɬʠʷ˂ɗཌྷบȽȼȺ๎Ȭ

ɞǿ

3)

Clean the disassembled relief valve with compressed air

and kerosene.

7

า

7

CAUTION

٢᎔ሳɥΈႊȬɞکնɂǾᄻȾȲȗሥ࿎ȽȼȟоɜȽȗ

ɛșί឴ʫɶʗɥᅔႊȪȹȢȳȨȗᴥʫɶʗᅔႊᐐɥֆ

ɓᴦǿ

When using compressed air, wear protective glasses to

prevent eye damage from dust or foreign matter (those

who wear glasses are included).

2

าᜤ

2

NOTE

ɾʩɁئᣅɒȽȼȾɛɝǾʚʵʠʐ˂ʛȾϾȟȕɞکնɂ̬૰

ȪȹȢȳȨȗǿ

Take care to check for dust contamination of the tapered section. If

scratches are visible on the tapered section of the relief valve,

replacement is necessary.

4)

ґᜓȻᣡɁਖ਼ᬲȺጸɒȹɞǿ

4)

Perform the above procedure in reverse to reassemble.

2

าᜤ

2

NOTE

ʁ˂ʵɁᆍ࿁ȽȼȟюȾоɜȽȗɛșȾาȪȹȢȳȨȗǿ

Ensure that foreign matter such as flakes from the sealing material

does not enter the tapered section during reassembly.

5)

ᥓከюɁɲɬȠɥᚐșǿ

5)

Bleed air from the piping.

1

ᥓከюɁɲɬȠȾȷȗȹɂ

1

Refer to “Lubricating Unit Air Removal” (page 197) for

details on bleeding air from the piping.

6)

ʴʴ˂ʟʚʵʠɁᝩɥᚐșǿ

6)

Adjust the relief valve.

Relief Valve

ʴʴ˂ʟʚʵʠ

Lock Nut

Adjusting Screw

Relief Valve Disassembly

Valve

Tapered Threaded Section

ʷʍɹʔʍʒ

ᝩɀȫ

ʴʴᴪʟʚʵʠґᜓَ

ʚʵʠ

ʐ˂ʛɀȫ

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......