ίަཟ೫ᬱᄻˢᜄ᚜

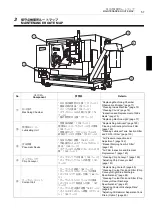

REGULAR INSPECTION LIST

56

Daily

Cleaning

“<Cleaning Slideway (Ball Screw) Protective Covers and Operator Door Rail>” (page 73)

“<Cleaning Cylinder Rear Section (Hollow Chuck Specifications)>” (page 74)

“Cleaning Chip Conveyor” (page 159) (Option)

Confirmation

Hydraulic Unit “Checking Pressure Gage” (page 95)

“Air Pressure Inspection and Adjustment” (page 142)

50 Hours

Cleaning

Coolant Cooling Unit “Cleaning Air Filter and Condenser” (page 138) (Option)

Oil Temperature Controller “Cleaning Air Filter and Condenser” (page 133)

150 Hours

Confirmation

V-Belt First Inspection for High Pressure Coolant Unit (page 166) (Option)

300 Hours

Cleaning

High Pressure Coolant Unit “Cleaning Notch Clean Filter” (page 164) (Option)

500 Hours

Cleaning

Cleaning coolant tank and filter (page 86)

Cleaning lubricating unit suction filter and fill port filter (page 130)

Cleaning lubricating unit line filter (page 129)

800 Hours

Replacement

High Pressure Coolant Unit “High Pressure Pump Oil Replacement” (page 166) (Option)

1000 Hours

Cleaning

Chuck disassembly and cleaning (Chuck manufacturer's manual)

Cleaning hydraulic unit suction strainer and tank (page 96)

Lubricating unit tank cleaning (page 130)

“Cleaning Electrical Cabinet Fan” (page 156)

Confirmation

Pneumatic device filter inspection (page 143)

High Pressure Coolant Unit “V-Belt Inspection” (page 166) (Option)

Replacement

“Inspection and Replacement of Slide Seals” (page 75)

1500 Hours

Cleaning

High Pressure Coolant Unit “Cleaning Coolant Tank” (page 165) (Option)

2000 Hours

Replacement

“Replacing Cooling Oil” (page 134)

Pneumatic Devices “Filter Element Replacement” (page 143)

Hydraulic Unit “Replacing Oil” (page 94)

1 Week

Confirmation

Machining Chamber Observation Window Inspection

2 to 3 Months

After Starting

Operation

Adjustment

“Adjusting Chip Conveyor Belt” (page 161)

(First slackening) (Option)

1 Year

Replacement

“Replacing Batteries” (page 157)

Hydraulic Unit “Filter Element Replacement of Line Filter” (page 98)

Adjustment

“Adjusting Chip Conveyor Belt” (page 161) (Option)

5 Years

Replacement

“Replacing Machining Chamber Observation Window” (page 71)

Inspection

Interval

Inspection Item

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......