97

บ٢ʰʕʍʒ

HYDRAULIC UNIT

4)

ᥓከɥɝ۶Ȭǿ

4)

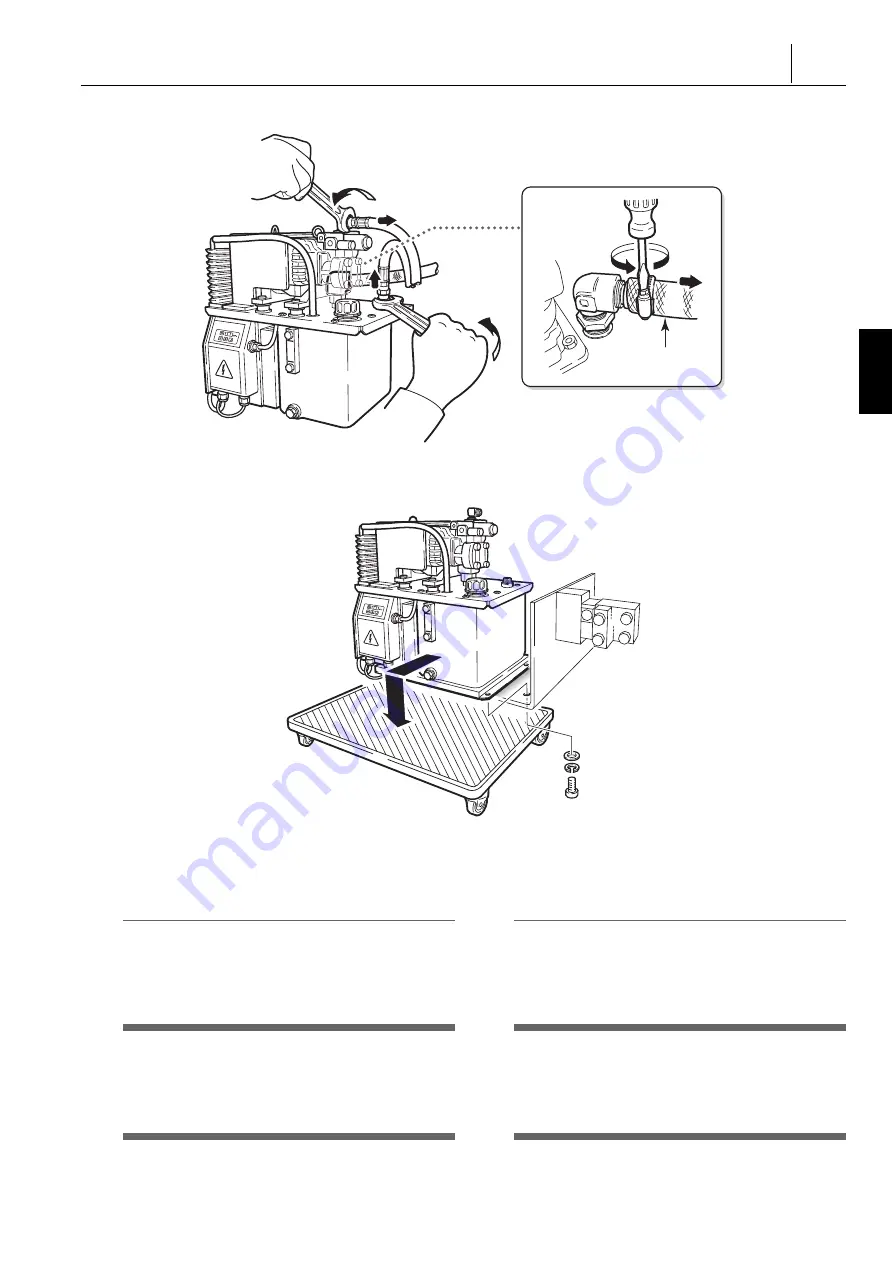

Disconnect the piping.

5)

ʉʽɹ˩Ɂʦʵʒɥɝ۶ȪǾบ٢ʰʕʍʒɥऀȠҋȬǿ

5)

Remove the bolts beneath the tank and pull the hydraulic

unit out from the base.

6)

ʉʽɹ˨ᬂɥɝ۶Ȭǿ

6)

Remove the tank upper plate.

7)

͏˩Ɂਖ਼ᬲȺɿɹʁʱʽʃʒʶ˂ʔɥຏોȬɞǿ

7)

Clean the suction strainer using the following procedure:

a)

ɿɹʁʱʽʃʒʶ˂ʔɥɝ۶Ȭǿ

a)

Remove the suction strainer.

2

าᜤ

2

NOTE

ɒ˨ȥᥓከɥʛɮʡʶʽʋȺِްȪǾʬʽɷ˂ʶʽʋȺɿ

ɹʁʱʽʃʒʶ˂ʔɥࡿȾوȪɑȬǿ

Clamp the suction pipe with a pipe wrench and turn the suction

strainer CCW using a monkey wrench.

b)

ɿɹʁʱʽʃʒʶ˂ʔɥཌྷบȺຏોȬɞǿ

b)

Clean the suction strainer with kerosene.

7

า

7

CAUTION

ཌྷบɥΈႊȬɞȻȠɂǾٍ֚ȾཌȟȽȗȞᆬᝓȪǾ

ԚґɥȷȤȹȢȳȨȗǿ

Use caution when using kerosene, and make sure

there is no open flame in the vicinity.

c)

ɿɹʁʱʽʃʒʶ˂ʔɥɲɬʠʷ˂Ȭɞǿ

c)

Dry the suction strainer using compressed air.

7

า

7

CAUTION

ᄻȾȲȗሥ࿎ȽȼȟоɜȽȗɛșί឴ʫɶʗɥᅔႊȪ

ȹȢȳȨȗᴥʫɶʗᅔႊᐐɥֆɓᴦǿ

Protective glasses must be worn to prevent eye

damage from dust or foreign matter (those who are

wearing glasses included).

Hose Band

ʥ˂ʃʚʽʓ

×

4

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......