81

˿ᢉɁৼɜȪᤆᢆ

SPINDLE WARM-UP

9

˿ᢉɁৼɜȪᤆᢆ

SPINDLE WARM-UP

ʣɬʴʽɺɁߧ֤ɥᆬίȬɞȲɔǾްఙᄑȾஃȪȹȢȳȨ

ȗǿ

Perform the spindle warm-up periodically to ensure optimum

bearing service life.

7

า

7

CAUTION

1.

ʹ˂ɹȽȪɁৰȺ˿ᢉɥوᢆȨȮȽȗȺȢȳȨȗǿ

ᵘൡಽɁᆍૺᵚ

1.

Do not rotate the spindle without a workpiece clamped

in the chuck.

[Machine damage]

2.

ৼɜȪᤆᢆɂᣮࢠΈႊȬɞʹ˂ɹǾȝɛɆʋʭʍɹ٢Ⱥ

ᚐȶȹȢȳȨȗǿɑȲǾʹ˂ɹɂȺȠɞȳȤߴवȺʚʳʽ

ʃɁɟȲɕɁɥΈႊȪȹȢȳȨȗǿ

ᵘʹ˂ɹɁ᭣ɆҋȪᵚ

2.

Perform the spindle warm-up with one of the usual

workpieces and with the usual chucking pressure.

Select a well-balanced workpiece that is as small in

diameter as possible.

[Workpiece ejection]

3.

ৼɜȪᤆᢆɂΈႊȬɞʋʭʍɹǾʹ˂ɹǾȝɛɆผщɁᜬ

߁وᢆᣱ࣊͏˩ȺᚐȶȹȢȳȨȗǿ

ᵘʹ˂ɹɁ᭣ɆҋȪǾ̷ᡵ̜ǾൡಽɁᆍૺᵚ

3.

Perform the spindle warm-up below the maximum

permissible rotation speed of the chuck, workpiece,

and fixture.

[Workpiece ejection/Serious injury/Machine damage]

4.

ৼɜȪᤆᢆɥᚐșҰȾʋʭʍɹǾʹ˂ɹǾผщǾȝɛɆࡾ

щȟᆬȾɝ͇ȤɜɟȹȗɞȞᆬᝓȪȹȢȳȨȗǿ

ᵘʹ˂ɹɁ᭣ɆҋȪǾ̷ᡵ̜ǾൡಽɁᆍૺᵚ

4.

Ensure that the chuck, workpiece, fixture, and tool are

mounted securely before performing the spindle

warm-up.

[Workpiece ejection/Serious injury/Machine damage]

5.

وᢆࡾщ˿ᢉɁৼɜȪᤆᢆɂΈႊȬɞࡾщʥʵʊɁᜬ߁و

ᢆᣱ࣊͏˩ȺᚐȶȹȢȳȨȗǿᴥʩ˂ʴʽɺ̈́റᴦ

5.

Perform the rotary tool-spindle warm-up at or below

the maximum permissible rotation speed of tool holder.

(Milling specifications)

6.

وᢆࡾщ˿ᢉȾɝ͇ȤɞࡾщɂǾ˿ᢉఊᯚوᢆᣱ࣊͏˨

وȬȦȻȟȺȠɞߴवࡾщɥΈႊȪȹȢȳȨȗǿᴥʩ˂ʴ

ʽɺ̈́റᴦ

6.

The tool to be mounted on the rotary tool-spindle must

be a small diameter tool that can be rotated at the

maximum spindle speed or more. (Milling

specifications)

9-1

ුஓɁৼɜȪᤆᢆ

Daily Spindle Warm-Up

ໃੵоऻǾൡಽɥᤆᢆȬɞҰȾǾ˩᚜ȾिȶȹৼɜȪᤆᢆ

ɥᚐȶȹȢȳȨȗǿوᢆࡾщ˿ᢉɁکնɕպറȾৼɜȪᤆᢆ

ɥᚐȶȹȢȳȨȗǿᴥʩ˂ʴʽɺ̈́റᴦ

After turning on the power, perform the spindle warm-up

referring to the table below before operating the machine.

Perform the spindle warm-up by the same procedure for rotary

tool-spindle. (Milling specifications):

2

าᜤ

2

NOTE

छஓΈႊȬɞӏࡾʡʷɺʳʪɁఊᯚوᢆᣱ࣊ɥژໄȾȪȹᚐȶȹȢȳ

Ȩȗǿ᚜юɁ

%

ɂछஓΈႊȬɞӏࡾʡʷɺʳʪɁఊᯚوᢆᣱ࣊Ⱦߦ

Ȭɞလɥ᚜ȪɑȬǿ

Adjust the rotation speed for warm-up based on the maximum rotation

speed for the machining programs used for the day. The percentage in

the table below indicates the ratio to the maximum rotation speed of

the machining programs of that day.

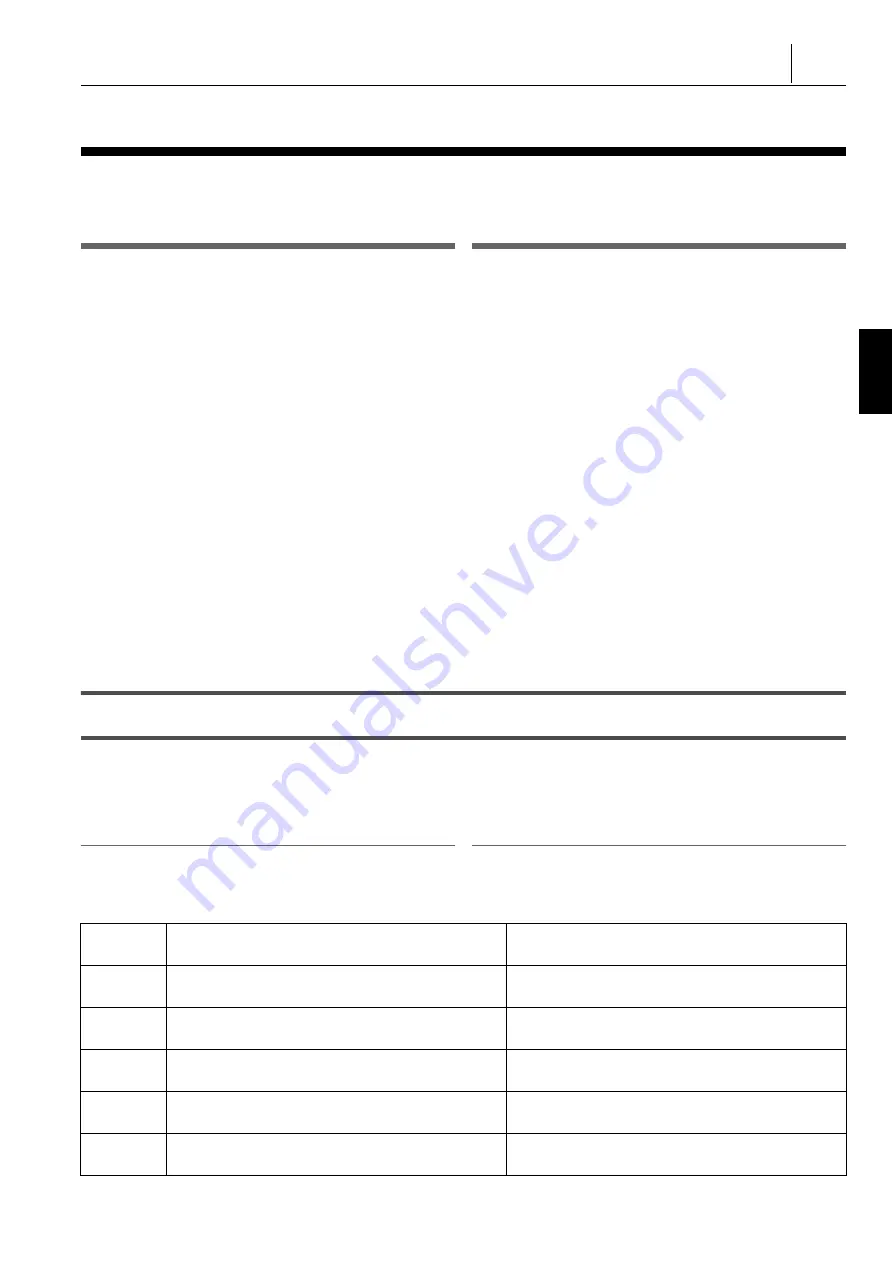

᪡

Step

ৼɜȪᤆᢆᣱ࣊

Warm-Up Speed

ᩖ

Time

1

5 %

10

ґ

10 minutes

2

25 %

10

ґ

10 minutes

3

50 %

5

ґ

5 minutes

4

75 %

5

ґ

5 minutes

5

100 %

5

ґ

5 minutes

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......