˿ᢉɁৼɜȪᤆᢆ

SPINDLE WARM-UP

82

ᴹʡʷɺʳʪᴻ

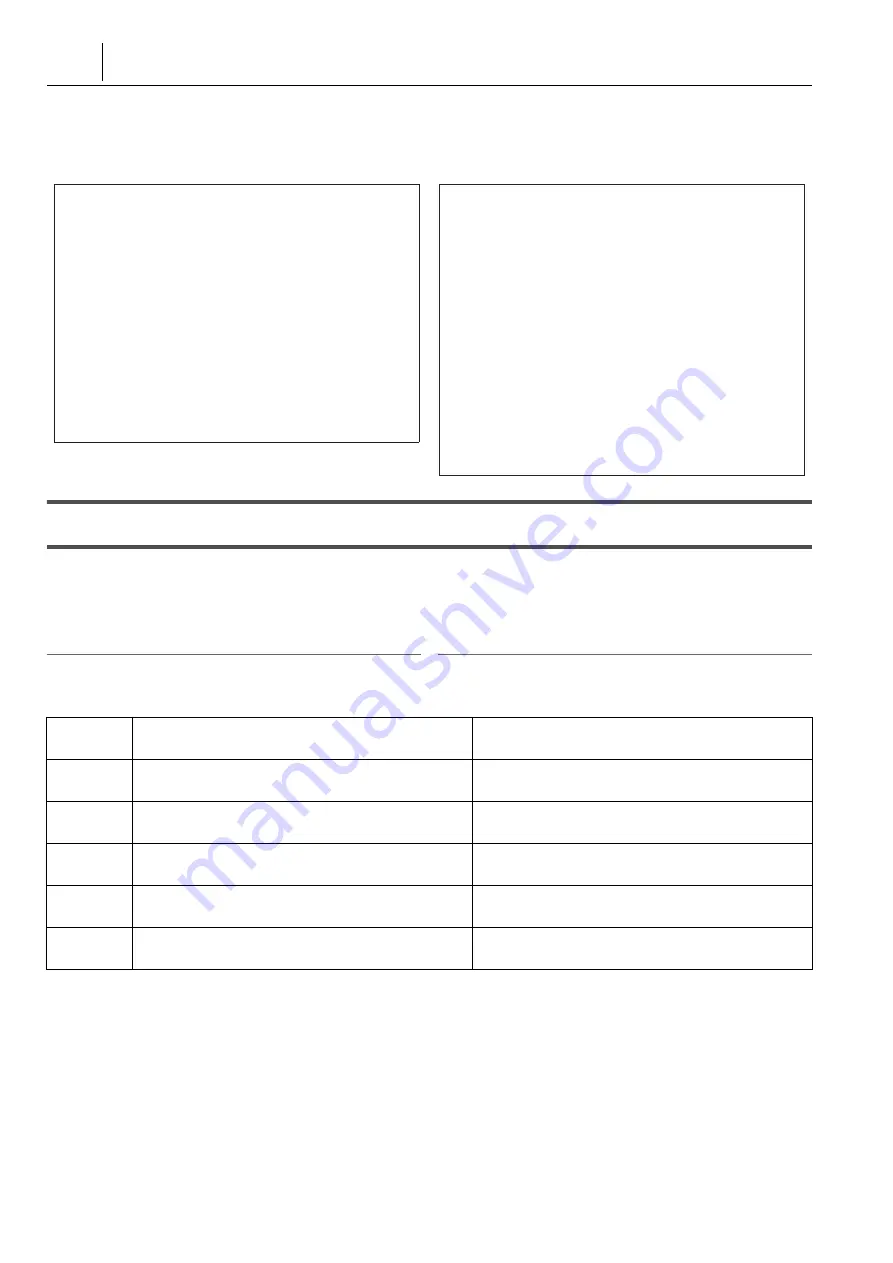

<Program example>

छஓΈႊȬɞӏࡾʡʷɺʳʪɁఊᯚوᢆᣱ࣊ɥ

2000 min

1

Ȼ

ȪȲکնɁʡʷɺʳʪɥ˩ᜤȾᇉȪɑȬǿ

The warm-up program shown below is for cases where the

maximum rotation speed for the machining programs of the

day is 2000 min

1

.

9-2

ᩋఙᩖϦඨऻɁৼɜȪᤆᢆ

Spindle Warm-Up after Extended Idle Period

ൡಽɥ

2

ᩖ͏˨ϦඨȪȲऻǾѓ࣊ൡಽɥᤆᢆȬɞȻȠɂǾ

˩᚜ȾिȶȹৼɜȪᤆᢆɥᚐȶȹȢȳȨȗǿوᢆࡾщ˿ᢉɁ

کնɕպറȾৼɜȪᤆᢆɥᚐȶȹȢȳȨȗǿᴥʩ˂ʴʽɺ̈́

റᴦ

Perform the spindle warm-up before restarting the machine

after an idle period of two weeks or more, referring to the table

below. Perform the spindle warm-up by the same procedure for

rotary tool-spindle. (Milling specifications):

2

าᜤ

2

NOTE

ࢠႊఊᯚوᢆᣱ࣊ɥژໄȾȪȹᚐȶȹȢȳȨȗǿ᚜юɁ

%

ɂࢠႊఊ

ᯚوᢆᣱ࣊ȾߦȬɞလɥ᚜ȪɑȬǿ

Adjust the rotation speed for warm-up based on the regularly used

maximum rotation speed. The percentage in the table below indicates

the ratio to the regularly used maximum rotation speed.

O0001;

G97 S100 M03;

G04 X600.0;

S500;

G04 X600.0;

S1000;

G04 X300.0;

S1500;

G04 X300.0;

S2000;

G04 X300.0;

M05;

M30;

O0001;

M45;

G97 S100 M13;

G04 X600.0;

S500;

G04 X600.0;

S1000;

G04 X300.0;

S1500;

G04 X300.0

S2000;

G04 X300.0;

M05;

M46;

M30;

<For Spindle>

<For Rotary Tool-Spindle>

ᴹ˿ᢉႊᴻ

ᴹوᢆࡾщ˿ᢉႊᴻ

᪡

Step

ৼɜȪᤆᢆᣱ࣊

Warm-Up Speed

ᩖ

Time

1

5 %

60

ґ

60 minutes

2

25 %

15

ґ

15 minutes

3

50 %

10

ґ

10 minutes

4

75 %

10

ґ

10 minutes

5

100 %

60

ґ

60 minutes

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......