85

ɹ˂ʳʽʒʰʕʍʒ

COOLANT UNIT

•

ɹ˂ʳʽʒɥ෩ȺȪȹȞɜʉʽɹȾᛃፈȪȹȢȳȨ

ȗǿ

• Add diluted coolant mixture to coolant tank after

mixing in a separate container.

•

ɹ˂ʳʽʒʫ˂ɵ˂Ɂᇉ༟࣊ȺΈႊȪȹȢȳȨȗǿ

ɹ˂ʳʽʒʫ˂ɵ˂Ɂᇉ༟࣊ȺΈႊȪȽȗȻǾҒҭॴ

ȟমȢȽȶȲɝǾൡಽɗʹ˂ɹȟȨɆȹǾൡಽɁᆍૺȾ

ȷȽȟɝɑȬǿɑȲǾӏࡾጀ࣊ȾɕমफᬭɥՒɏȪɑ

Ȭǿ

• Use coolant at the concentration specified by the

supplier. If coolant of improper concentration is

used, workability is degraded and rusting of the

machine and workpiece occurs, causing damage to

the machine and adversely affecting machining

accuracy.

•

ɹ˂ʳʽʒɥȬɞ෩Ɂܟᆕ࣊ȾȷȗȹɂǾɹ˂ʳ

ʽʒʫ˂ɵ˂ȾȝץնȮȢȳȨȗǿᆕ࣊ȟᯚȗȻɹ˂ʳ

ʽʒȟґᫌȪǾᆕ࣊ȟͲȗȻฮȴȟᄉႆȪɗȬȢȽɝ

ɑȬǿ

• Contact the coolant supplier for the recommended

hardness levels of water used to dilute the coolant.

Diluting the coolant using water that is too hard

makes the coolant separate, and diluting it using

water whose hardness is too low makes the coolant

froth easily.

•

ɹ˂ʳʽʒɥᛃЭȬɞȻȠȾǾаȾ෩ȳȤɥፕȡᠴȨȽ

ȗȺȢȳȨȗǿ

• Do not mix water and concentrated coolant in the

coolant tank.

10-2

ɹ˂ʳʽʒɁᛃፈ

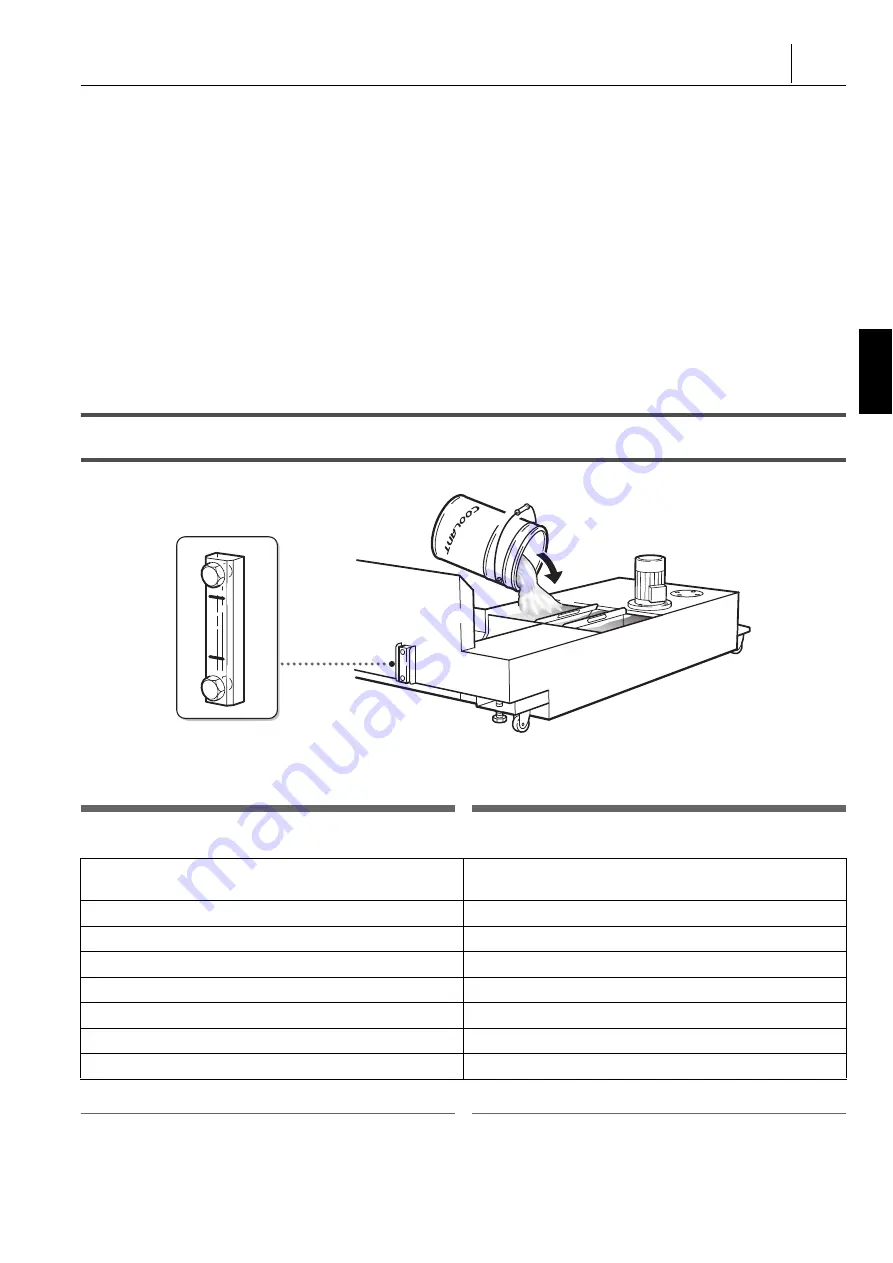

Replenishing Coolant

บᬂɁ˨᪅ɑȺɹ˂ʳʽʒɥาȣǿ

Supply coolant up to the upper limit on the oil level gage.

7

า

7

CAUTION

ɹ˂ʳʽʒʟɭʵʉɥɝ͇ȤȲৰȺᛃፈȪȹȢȳȨȗǿ

When supplying coolant, ensure the coolant filters are

installed.

2

าᜤ

2

NOTE

[ ]

юɁୣϏɂʋʍʡɽʽʣʮᑔᬂҋȪ̈́റᴥɴʡʁʱʽᴦɁکնȺ

Ȭǿ

Values in [ ] are for the chip conveyor rear discharge specifications

(option).

Oil Level Gage

บᬂ

ൡሗջ

Model

ʉʽɹ߁ᦀᴥ

L

ᴦ

Tank Capacity (L)

NL1500, NL2000

235 [240]

NL2500/700

246 [240]

NL2500/1250

345

NL3000/700

300 [320]

NL3000/1250

370

NL3000/2000

470

NL3000/3000

540

Summary of Contents for NL1500/500

Page 8: ......

Page 9: ...CONTENTS FOR SAFE MACHINE OPERATION REGULAR MAINTENANCE TROUBLESHOOTING INDEX...

Page 10: ......

Page 19: ...FOR SAFE MACHINE OPERATION...

Page 50: ......

Page 51: ...1 1 CHAPTER 1 CHAPTER 1 REGULAR MAINTENANCE...

Page 167: ...2 2 CHAPTER 2 CHAPTER 2 TROUBLESHOOTING...

Page 181: ...181 ZERO POINT RETURN COMMAND ALARM TRIGGERED X X Axis Z Z Axis Y Y Axis...

Page 232: ......

Page 240: ......

Page 242: ......