OPERATION PANELS A-27

5-6-5

Spindle OFF Mode Function

The spindle OFF mode function is used to determine whether or not the following M code

functions are actually executed when checking a program without chucking a workpiece in the

machine.

When checking a new program, automatic operation is executed without rotating the spindle and

supplying coolant to check tool offset amounts, interference between tools and a chuck, etc.

It is made valid or invalid on the OPERATION PANEL screen.

Function selection key

(CUSTOM1)

[OPE. PANEL]

For the procedure to check a program without chucking a workpiece, refer to

page E-12 (6).

<When the spindle OFF mode function is valid>

When the spindle OFF mode function is made valid, the dry run function also becomes valid and

the indicator above the

(STOP) switch and the indicator in the dry run switch

blink.

If automatic operation is executed in this state, the program advances to the next block without

executing the M code functions indicated in the table above.

Although axis movement commands are executed, the axes are moved at the feedrate set by the

OVERRIDE dial since the dry run function is valid.

It is not possible to execute automatic operation with a workpiece clamped in the spindle

chuck when the spindle OFF mode function is valid.

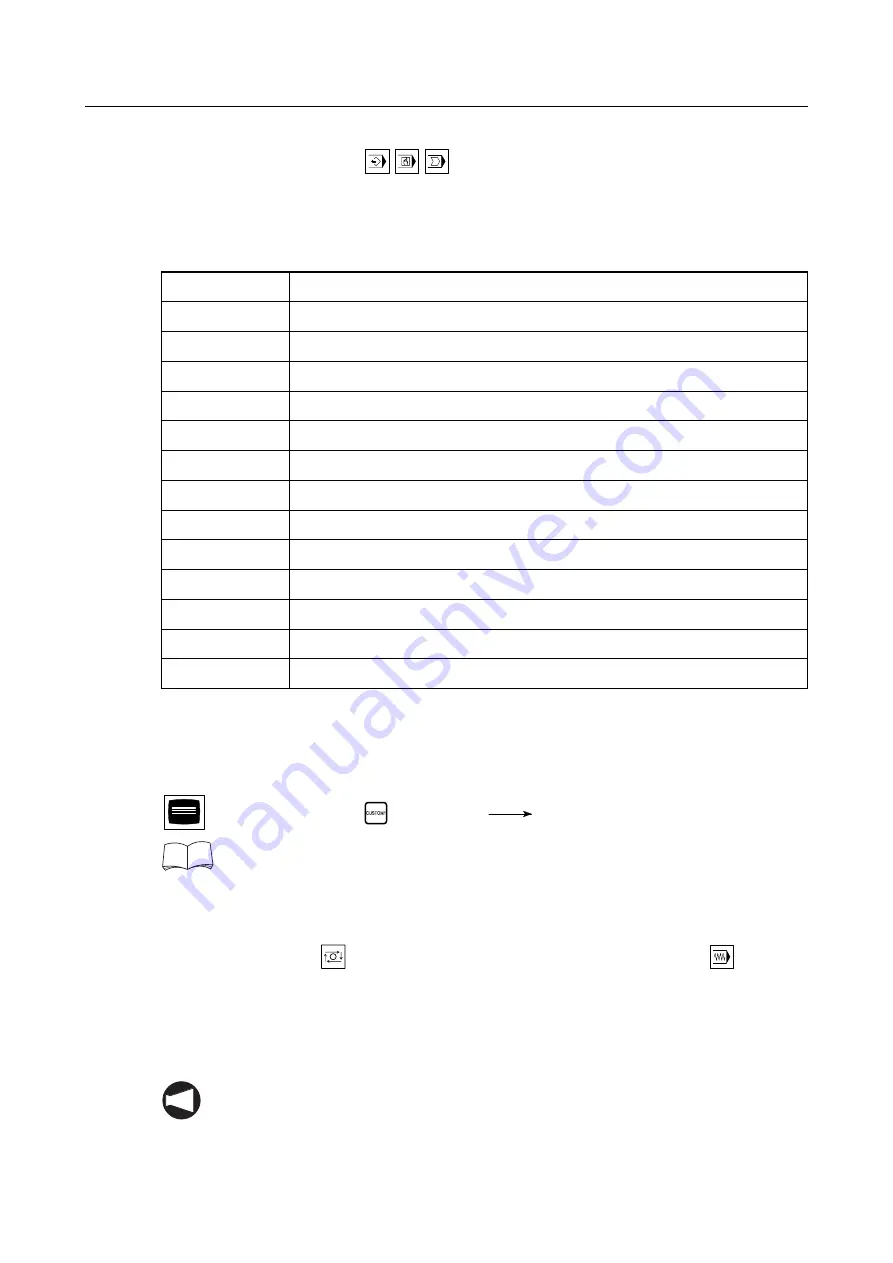

M Code

Function

M03

Spindle start (normal)

M04

Spindle start (reverse)

M08

Coolant supply

M13

Rotary tool spindle start (normal) (M type)

M14

Rotary tool spindle start (reverse) (M type)

M19

Spindle orientation (option)

M64

Robot service call (robot specification)

M203

Spindle 2 start (normal) (S type)

M204

Spindle 2 start (reverse) (S type)

M219

Spindle 2 orientation (option) (S type)

M319

Rotary tool spindle zero point return (M type)

M382

Chip removal coolant ON (option)

M384

Spindle orientation and ceiling shutter open (option)

NOTE