CHUCKING C-25

4

CHUCK JAW STROKE END DETECTION FUNCTION

When gripping a workpiece, the gripping force of the chuck is low if the workpiece is clamped near

the stroke end of the master jaw. Rotating the spindle in this condition is hazardous because the

workpiece may disengage from the chuck.

Therefore, the "chuck jaw stroke end detection function" is provided to disable spindle start if a

workpiece is clamped by the chuck near the master jaw stroke end. Switches are mounted to the

chuck opening/closing cylinder to detect the stroke ends. This prevents the spindle from being

started with the workpiece clamped near the master jaw stroke end to ensure the safety of

operators.

1.

The chuck jaw stroke end detection function is available only when the machine is

shipped with the chuck and cylinder recommended by Mori Seiki.

2.

Depending on the chuck and cylinder specification, optional chuck clamp/unclamp

detecting switches may be equipped as a substitute for chuck jaw stroke end

detecting switches. With the chuck clamp/unclamping detecting switches, it is not

possible to detect clamping of a workpiece if it is clamped in the chuck near the

master jaw stroke end.

Depending on the combination of the selected specifications, the chuck jaw stroke

end detection switch function or the chuck clamp/unclamping detection switch

function may not be installed. For details, contact Mori Seiki.

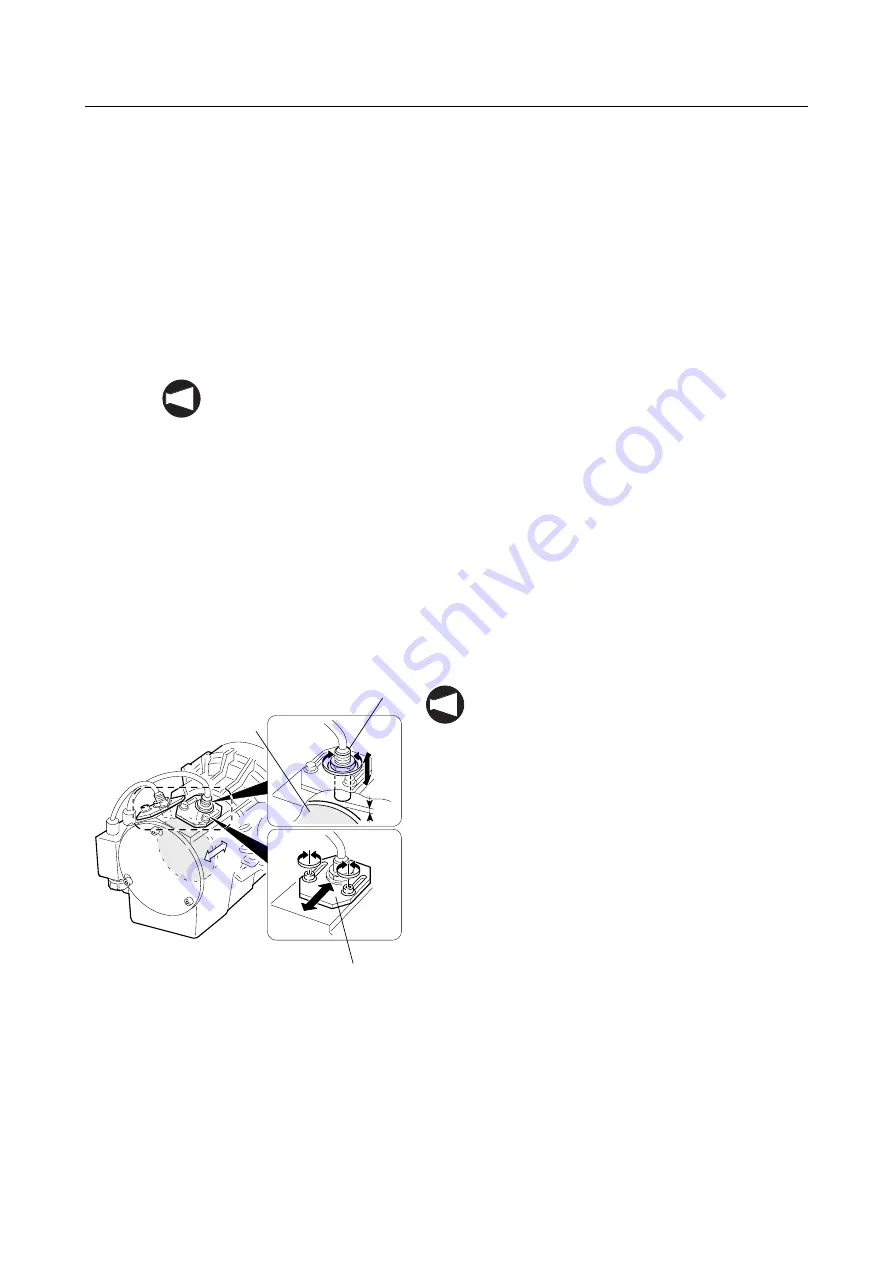

<Construction>

Location and construction of the detecting switches are shown below.

1.

The illustration shows the construction of a

hollow cylinder. This may be different from

the cylinder used in your machine.

2.

The detecting switch is adjusted before

shipping.

NOTE

Dog

Proximity switch

Bracket

1 mm

NOTE