morsedrum.com

Copyright 2022 - Morse Mfg. Co., Inc.

Form OM510 (249855-______)

(Updated 23 Mar, 2022)

3

The Specialist In Drum Handling Equipment

Model 510

Vertical-Lift, 60”, Manual Lift & Tilt

Operator’s Manual for Morse Vertical-Lift Drum Pourer Model 510

Serial Number 249855 to ______

Machine Description

The Model 510 Vertical-Lift Drum Pourer will pour a drum at up to 60” (152

cm) high, measured from the floor to the lowest point of a horizontal drum. It

is designed to lift, transport, and dispense a ribbed 55-gallon (210 liter) steel

drum 22.5” (56 cm) in diameter, as well as a fiber drum between 22” and

23.5” (56 to 59.7 cm) in diameter.

Maximum full-drum capacity is 800 Lb. (363 kg). Capacity is derated to

500 Lb. (227 kg) for a half-full drum. Half-full rating is based on the tilt

mechanism’s capacity for handling an unbalanced bottom-heavy drum.

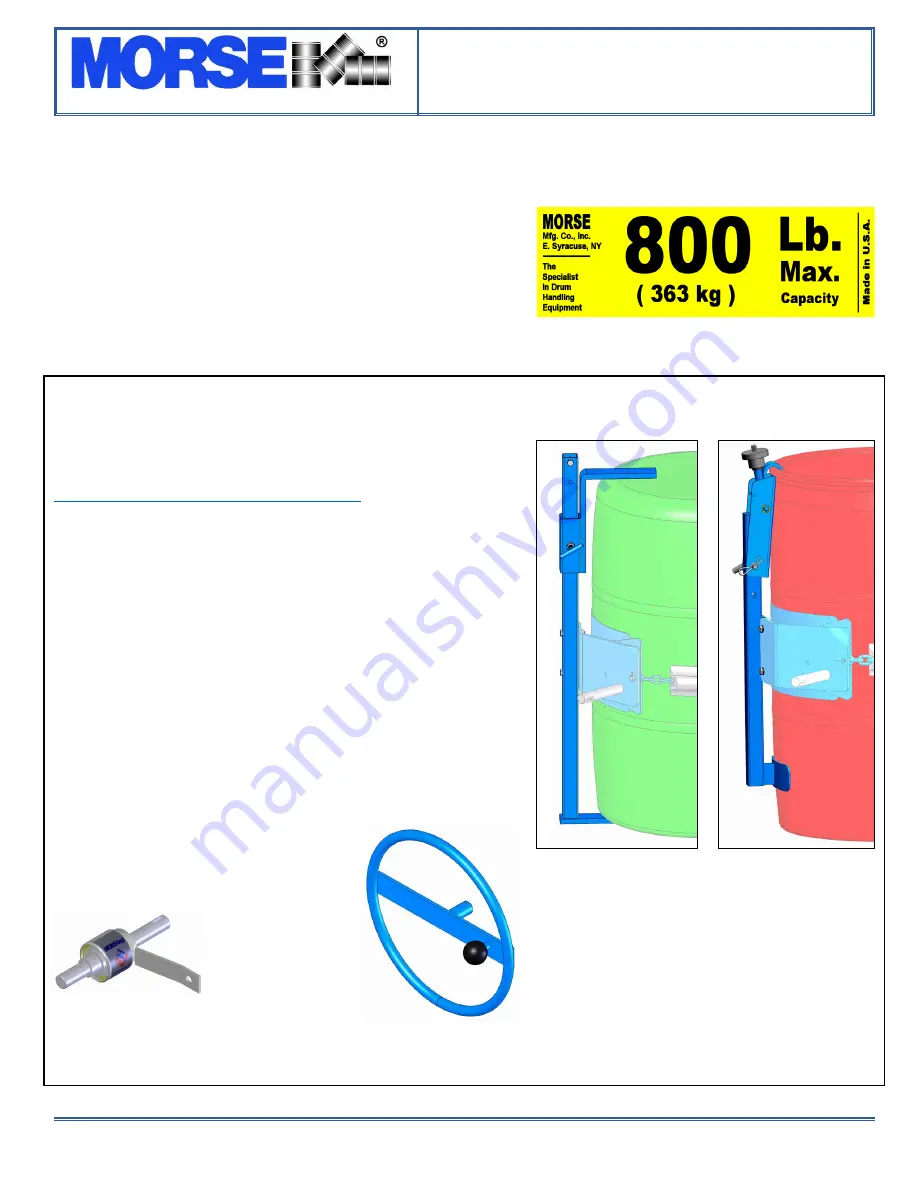

Hand Wheel

Kit # 2690-P

16” (40.6 cm) diameter

Hand Wheel

with speed knob.

Replaces standard

Pull Chain to turn drum.

Kit for customer

to install on

EXISTING manual

tilt drum handler.

MORStop

TM

Tilt-Brake

Kit # 3900-P

Automatically holds

drum tilt angle until

you move it.

Kit for customer

to install on

EXISTING manual

tilt drum handler.

55/30 Series Diameter Adapters

for drum with diameter smaller than 22” (56

cm). To handle a smaller drum, insert the correct size Diameter Adapter into

the standard drum holder. See Diameter Adapter info at:

https://morsedrum.com/products/diameter-adapters

ONLY Diameter Adapters for drum with 17.5” (44.5 cm) diameter or smaller

have integrated brackets to prevent drum slipping length-ways.

NOTE:

For 30-gallon (114 Liter) PLASTIC drum, insert Diameter Adapter;

AND

install Bracket or Top Rim Clamp to prevent drum slipping.

IMPORTANT:

To prevent 30 to 55 gallon (114 to 210 L) size plastic drum from

slipping, you

MUST

install either Top Rim Clamp Kit or Bracket Assembly Kit.

1.

Bracket Assembly Kit # 4556-P

is

required

to handle a RIMLESS

plastic drum (figure 2.1), and is also recommended for a fiber drum.

The Bracket adjusts for a 31” to 39” (79 to 99 cm) tall drum.

You can also handle a rimmed drum with the Bracket installed.

2.

Top Rim Clamp Kit # 4560B-P

to handle a RIMMED plastic drum

(figure 2.2). Install the Top Rim Clamp Kit to handle a RIMMED

plastic, steel or fiber drum with suitable top rim.

ACCESSORIES

Figure 2.2

Kit # 4560-P

Install Top Rim Clamp Kit

to handle RIMMED plastic

drum

Figure 2.1

Kit # 4556-P

Install Bracket Assembly Kit

to handle RIMLESS or

RIMMED plastic drum