The Specialist In Drum Handling Equipment

Model 515-N-115

Vertical-Lift Drum Pourer, Scale-Equipped,

60”, DC Power Lift and Tilt

Operator’s Manual for Morse Model 515-N-115

with Serial Number 249855 to ______

morsedrum.com

Copyright 2022 - Morse Mfg. Co., Inc.

Form OM515-115 (249855-______)

(Updated 23 Feb, 2022)

4

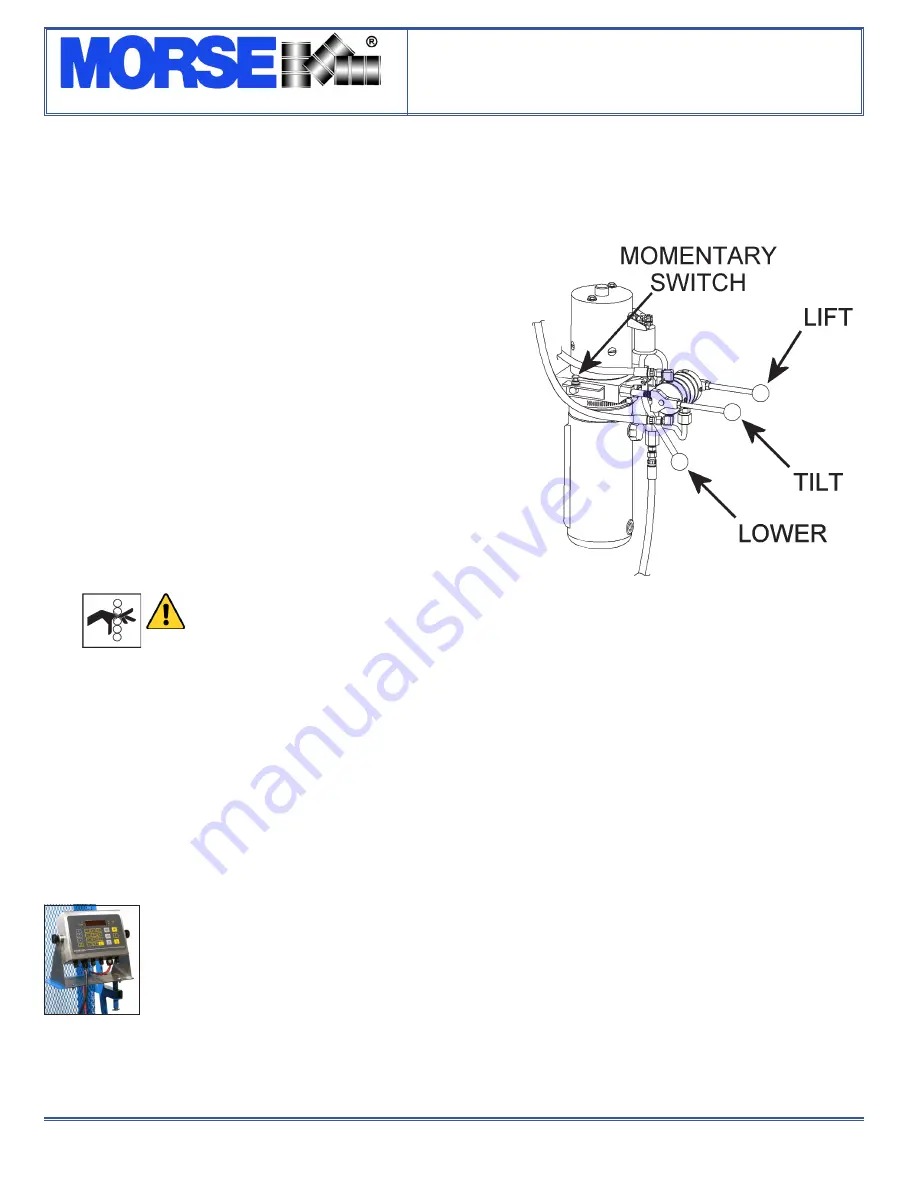

Controls

The Morse Vertical-Lift Drum Pourer is manually propelled and

steered. The drum lift and tilt controls are powered by a 12V DC

motor with a momentary switch. There are two functions for the

operator to control (Figure 3.1):

1. LIFT and Lower Function for vertical positioning of the drum

To raise the drum

Turn the motor on by holding the momentary switch in the on position.

With the motor on, raise the LIFT handle.

To lower the drum

With the motor off, push in the LOWER handle.

2. TILT Function to control the degree of rotation of the drum

To tilt the drum forward for pouring

Turn on the motor by holding momentary switch in the on position.

With the motor on, raise the tilt handle.

To return the drum to vertical position

Turn on the motor by holding momentary switch in the on position.

Push the tilt handle down.

WARNING

- Watch out for pinch points

Stay clear of moving parts. Operator should

remain behind the push handle during the lift

operation.

Floor Lock

Floor lock handle is located on left side of push handle. Pulling floor lock handle toward operator until it locks in down position activates

the floor lock. When floor lock is activated it prevents unwanted free wheeling of unit. Floor conditions determine effectiveness of floor

lock. Operator should verify its holding action before depending on it to hold.

Drum Holder Assembly

MORCINCH

TM

Drum Holder assembly (“saddle”) is the component on Vertical-Lift Drum Pourer intended to hold drum. Carriage assembly

moves vertically along mast to position drum holder assembly at correct height to secure drum around it’s middle using cinch chain and

ratchet tightening system.

The MORCINCH

TM

Drum Holder accepts accessories to handle plastic drum, fiber drum, or a smaller diameter drum.

Scale

The scale is simple to use and to read enabling accurate batching by weight. The touch pads include numbers for

tare entry. Four load cells accurately sense the weight regardless of the tilt angle of the drum. Battery saving “sleep”

mode turns indicator off when scale is not in use.

N-Type Scale

Economical general purpose instrument for use in a variety of weighing applications. NOT for use in hazardous areas.

Powered by five ordinary alkaline D-cell batteries.

“N” Type scale

indicator NOT

for hazardous

environments.

Figure 3.1