The Specialist In Drum Handling Equipment

Model 83

Pail Handler

operator’s Manual for Morse Model 83

serial number 0819 to ____ (MMYY)

morsedrum.com

Copyright 2020 - Morse Mfg. Co., Inc.

Form PL83 (0819-____)

(Updated 3 Jun, 2020)

6

operating Instructions

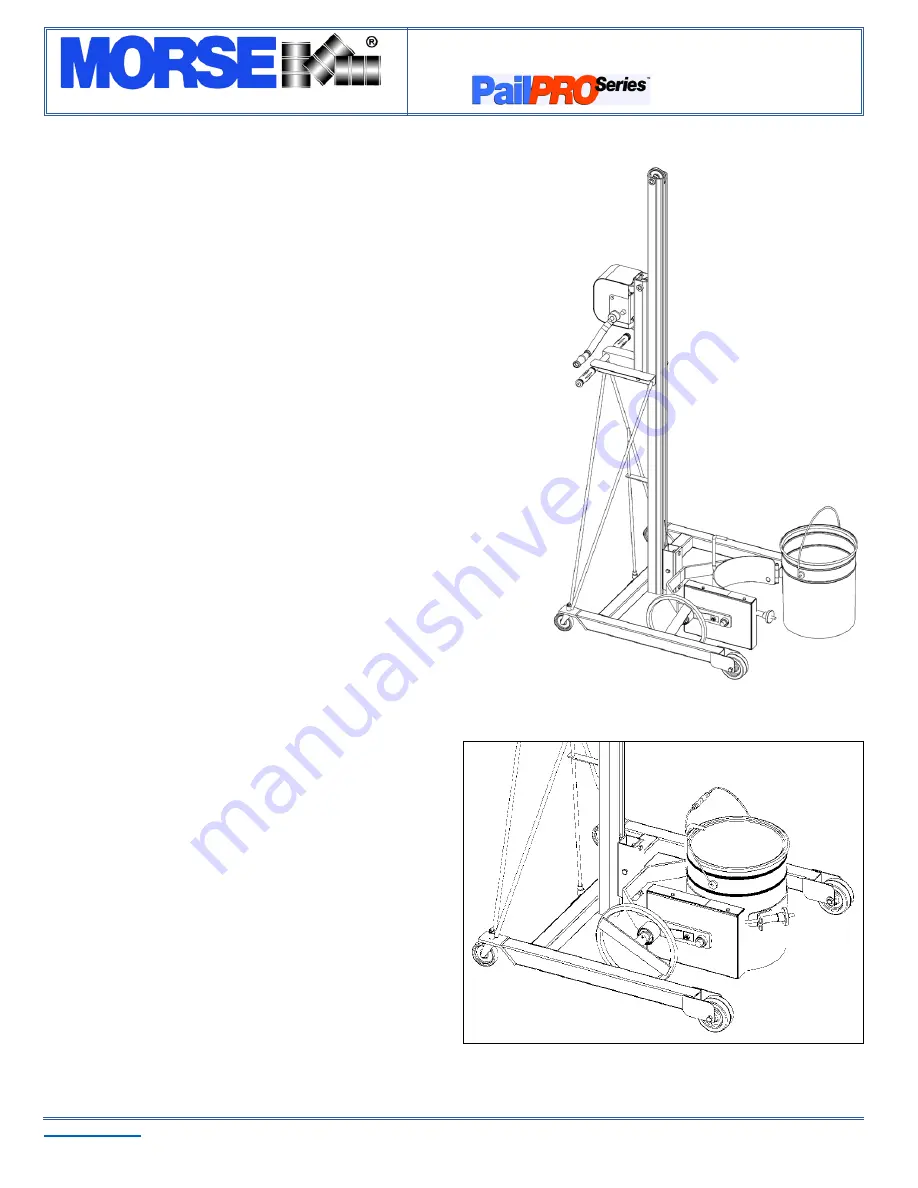

1. Push the Pail Handler to the pail.

2. Using the cable winch, crank the handle to position the pail holder assembly

with the back band at the middle of the pail. (see Figure 1). If the pail has a

pivoting wire handle, swing it to lay on the front side to clear the back band.

With the front band hinge plate and clamp screw knob swung open, push

the unit forward until the back band rests firmly against the pail. Engage the

screw down floor lock.

3.

Attaching the pail:

First, swing pivoting wire handle to lay on the back band

side of the saddle. Next, close the front band hinge plate tightly against the

pail (see Figure 2). Swing the clamp screw knob and engage the threaded

rod into the slot on the front band hinge plate as shown in Figure 2. Tighten

the clamp screw knob to secure the pail into the saddle.

4. Crank the cable winch to lift pail clear of floor. Disengage floor lock. Roll to

dispensing location.

5. Crank cable winch to raise pail to desired pouring height. Engage the screw-

down floor lock. Tilt the pail forward until desired pouring angle. The pail will

remain in this position.

6. When dispensing is complete, tilt pail back to upright position. Disengage the

floor lock and lower the pail to transporting height; about 6” off the floor.

7. Push the unit to the pail storage area and lower to the floor. Engage the floor

lock. Loosen the clamp screw knob until it can be released from the slot in the

front band hinge plate. Roll Pail Handler away from pail.

Maintenance

Periodic inspection for the general condition of structural and

mechanical components is imperative for safe and efficient

operation.

Periodically inspect all moving parts, framework, and contact areas

for signs of wear, fatigue, or loosening. Tighten, adjust, or replace

parts as necessary to prevent failure and maintain proper function.

Periodically lubricate vertical track rollers, casters, wheels, saddle

shafts, and cable pulleys and/or shafts.

Figure 1

Figure 2