morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc.

Form OM900 (294521-______) (Updated 12 Jun, 2019 3:07 PM)

3

operator’s Manual for Morse < PILot > Power-Propelled Drum Pourer Model 900

serial number 294521 to ______

The Specialist In Drum Handling Equipment

Model 900

Power-Propelled Drum Pourer

Machine Description

The Model 900 < PILOT > Power-Propelled Drum Pourer will pour a drum at up to

10.5’ (3.2 m) high, measured from the floor to the lowest point of a horizontal drum. It is

designed to lift, transport, and dispense a ribbed 55-gallon (210 liter) steel drum 22.5”

(57 cm) in diameter, as well as a fiber drum between 22” and 23.5” (56 to 59.7 cm) in

diameter.

The maximum full-drum capacity is 1500 Lb. (680 kg) The capacity is derated to 800 Lb.

(363 kg) for a half-full drum. The half-full rating is based on the tilt mechanism’s capacity

for handling an unbalanced bottom-heavy drum.

options

A smaller diameter drum can be handled with the correct size 55/30

•

Series Diameter Adaptor installed (see

Diameter Adaptor literature

).

The

•

Bracket Assembly

(Part # 4556-P) is

required

to handle a plastic

drum without a top rim (see figure 2.1). It is also recommended to more

securely handle a fiber drum. You can use the Bracket Assembly with

a 55-gallon (210 liter) plastic, steel or fiber drum. The brace at top and

bottom of the drum prevent it from slipping lengthways through the drum

holder. It adjusts for a drum 31” to 39” (79 to 99 cm) tall.

The

•

top Rim Clamp

(Part # 4560-P) grips the upper rim of your drum

to prevent it from slipping through the drum holder (see figure 2.2). To

handle a 55-gallon (210 liter) plastic drum with top rim, you

must

install

either the Bracket Assembly or the Top Rim Clamp. You can use the Top

Rim Clamp with a 55-gallon (210 liter) plastic, steel or fiber drum with

suitable top rim.

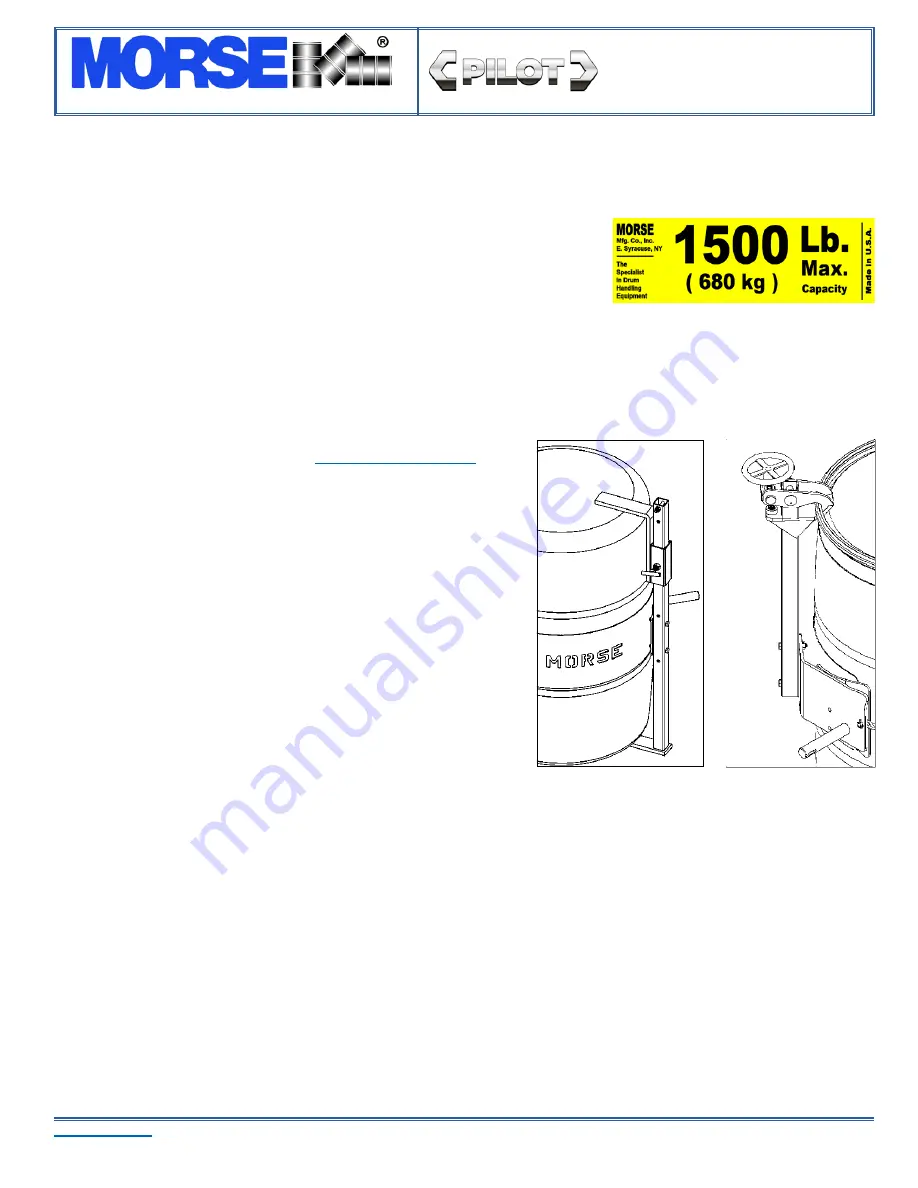

Figure 2.2

Plastic drum being lifted

with part number 4560-P

Top Rim Clamp Assembly

installed.

Figure 2.1

Plastic drum being lifted with

part number 4556-P Bracket

Assembly installed.