DB15

INSTALLATION AND OPERATING INSTRUCTIONS

10

11

DB15

INSTALLATION AND OPERATING INSTRUCTIONS

WATER SYSTEM CONNECTIONS

Outlines of some possible installation schemes are

shown here. In both of them:

●Possible boiling is safely accommodated by a

vent pipe leading directly to an open feed and

expansion tank.

●A c50°C low-level thermostat brings the pumped

system 'on' only when the fire is hot. It prevents

stored hot water from being depleted and cold

water chilling the boiler. Vital to prevent corrosion.

●A c90°C thermostat can close to override all

other controls and operate the central heating

pump to dissipate heat if there is a risk of boiling.

●There are time and room-temperature controls

controlling the central-heating pump.

●Hot water for taps is not separately controlled, it

may become scalding hot - consider fitting a

thermostatic mixing valve.

●An electric immersion heater is provided for

summer hot water.

Temperatures are approximate and will vary.

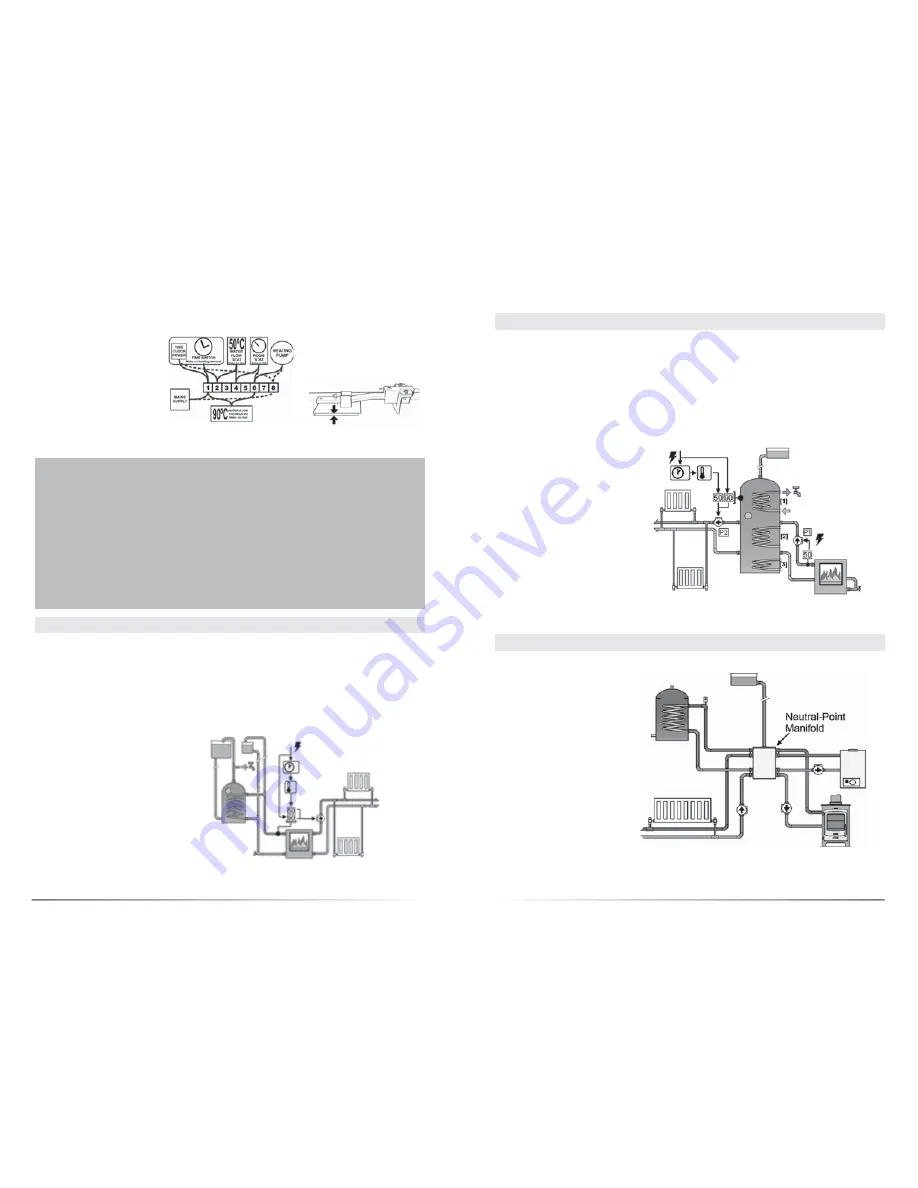

Scheme 1: TRADITIONAL 2-SIDE

Compact and quick to heat. Stores hot water

for taps, but radiators will go cold if the fire

goes out. Recommended for occasional use or

where long-burning mineral fuels are used.

One side of the boiler feeds, by gravity circulation

alone, an indirect coil to heat a hot-water storage

cylinder and has feed and vent connections to a

small open expansion tank. (Gravity piping

requires careful calculation but will generally be

at

least

28mm diameter, rise continually and have a

horizontal distance from the boiler of no more than

its vertical distance above it.)

The other side of the boiler connects to the

pumped central heating circuit, which activates

only when a time-clock, room thermostat and

c50°C pipe thermostat (on the domestic hot-water

side flow pipe near to the boiler), are all 'closed'.

A second electrical supply feeds a pipe thermostat

on the flow pipe to domestic water very near to the

boiler and set to close above c90°C, such that if

there is risk of boiling the central-heating pump will

always operate to dissipate heat.

Scheme 2: THERMAL STORE

A large body of water is stored at a high

temperature, to supply both taps and central

heating when needed. High and low output

phases are evened-out; heating can operate

even if the fire is out, eg, next morning.

Recommended for all uses, and always where wood is the main fuel.

In one system, a 'combined' thermal store or 'heat bank' of about 300 litre capacity is directly heated by the boiler and has an indirect

coil [1] in its highest (hottest) part to supply tap water, below which the central-heating flow is taken-off as needed.

Pump (P1) circulates hot water from the boiler to the store only when a pipe thermostat on the boiler flow pipe is above c50°C. The,

separate, central heating pump (P2) operates only when the time-clock, room

thermostat and a second c50°C thermostat responsive to temperature in the store, are

all 'closed'. A second thermostat towards the top of the store closes at c90°C to

dissipate heat if there is risk of boiling.

Extra indirect coils may be provided at [2] to accommodate a supply from a second

central-heating boiler, and at [3] to receive relatively low-grade heat from solar panels.

LINK-UP TO ANOTHER BOILER

Your stove can be linked into an oil or gas central heating system and operate

completely automatically. One method is to use a thermal store system, like Scheme 2

above, with a separate coil (for pressurised boilers) or extra direct connections (for

open-vent boilers).

Another method uses a 'neutral point manifold' where both boilers are connected to the

manifold, which is in turn connected to the hot water and radiator circuits. Suitable

devices come from

www.esse.com

and

www.systemlink.ie

.

2

Scheme 1:

Traditional 2-side system with gravity hot water.

Recommended where mineral fuels are mainly to be used

Scheme 2:

Thermal store system.

Recommended for all uses, and always where wood is the main fuel.

Outline of multiple boiler Link-Up using a neutral-point

manifold

WATER SYSTEM CONNECTIONS

Outlines of some possible installation schemes are

shown here. In both of them:

●Possible boiling is safely accommodated by a

vent pipe leading directly to an open feed and

expansion tank.

●A c50°C low-level thermostat brings the pumped

system 'on' only when the fire is hot. It prevents

stored hot water from being depleted and cold

water chilling the boiler. Vital to prevent corrosion.

●A c90°C thermostat can close to override all

other controls and operate the central heating

pump to dissipate heat if there is a risk of boiling.

●There are time and room-temperature controls

controlling the central-heating pump.

●Hot water for taps is not separately controlled, it

may become scalding hot - consider fitting a

thermostatic mixing valve.

●An electric immersion heater is provided for

summer hot water.

Temperatures are approximate and will vary.

Scheme 1: TRADITIONAL 2-SIDE

Compact and quick to heat. Stores hot water

for taps, but radiators will go cold if the fire

goes out. Recommended for occasional use or

where long-burning mineral fuels are used.

One side of the boiler feeds, by gravity circulation

alone, an indirect coil to heat a hot-water storage

cylinder and has feed and vent connections to a

small open expansion tank. (Gravity piping

requires careful calculation but will generally be

at

least

28mm diameter, rise continually and have a

horizontal distance from the boiler of no more than

its vertical distance above it.)

The other side of the boiler connects to the

pumped central heating circuit, which activates

only when a time-clock, room thermostat and

c50°C pipe thermostat (on the domestic hot-water

side flow pipe near to the boiler), are all 'closed'.

A second electrical supply feeds a pipe thermostat

on the flow pipe to domestic water very near to the

boiler and set to close above c90°C, such that if

there is risk of boiling the central-heating pump will

always operate to dissipate heat.

Scheme 2: THERMAL STORE

A large body of water is stored at a high

temperature, to supply both taps and central

heating when needed. High and low output

phases are evened-out; heating can operate

even if the fire is out, eg, next morning.

Recommended for all uses, and always where wood is the main fuel.

In one system, a 'combined' thermal store or 'heat bank' of about 300 litre capacity is directly heated by the boiler and has an indirect

coil [1] in its highest (hottest) part to supply tap water, below which the central-heating flow is taken-off as needed.

Pump (P1) circulates hot water from the boiler to the store only when a pipe thermostat on the boiler flow pipe is above c50°C. The,

separate, central heating pump (P2) operates only when the time-clock, room

thermostat and a second c50°C thermostat responsive to temperature in the store, are

all 'closed'. A second thermostat towards the top of the store closes at c90°C to

dissipate heat if there is risk of boiling.

Extra indirect coils may be provided at [2] to accommodate a supply from a second

central-heating boiler, and at [3] to receive relatively low-grade heat from solar panels.

LINK-UP TO ANOTHER BOILER

Your stove can be linked into an oil or gas central heating system and operate

completely automatically. One method is to use a thermal store system, like Scheme 2

above, with a separate coil (for pressurised boilers) or extra direct connections (for

open-vent boilers).

Another method uses a 'neutral point manifold' where both boilers are connected to the

manifold, which is in turn connected to the hot water and radiator circuits. Suitable

devices come from

www.esse.com

and

www.systemlink.ie

.

2

Scheme 1:

Traditional 2-side system with gravity hot water.

Recommended where mineral fuels are mainly to be used

Scheme 2:

Thermal store system.

Recommended for all uses, and always where wood is the main fuel.

Outline of multiple boiler Link-Up using a neutral-point

manifold

WATER SYSTEM CONNECTIONS

Outlines of some possible installation schemes are

shown here. In both of them:

●Possible boiling is safely accommodated by a

vent pipe leading directly to an open feed and

expansion tank.

●A c50°C low-level thermostat brings the pumped

system 'on' only when the fire is hot. It prevents

stored hot water from being depleted and cold

water chilling the boiler. Vital to prevent corrosion.

●A c90°C thermostat can close to override all

other controls and operate the central heating

pump to dissipate heat if there is a risk of boiling.

●There are time and room-temperature controls

controlling the central-heating pump.

●Hot water for taps is not separately controlled, it

may become scalding hot - consider fitting a

thermostatic mixing valve.

●An electric immersion heater is provided for

summer hot water.

Temperatures are approximate and will vary.

Scheme 1: TRADITIONAL 2-SIDE

Compact and quick to heat. Stores hot water

for taps, but radiators will go cold if the fire

goes out. Recommended for occasional use or

where long-burning mineral fuels are used.

One side of the boiler feeds, by gravity circulation

alone, an indirect coil to heat a hot-water storage

cylinder and has feed and vent connections to a

small open expansion tank. (Gravity piping

requires careful calculation but will generally be

at

least

28mm diameter, rise continually and have a

horizontal distance from the boiler of no more than

its vertical distance above it.)

The other side of the boiler connects to the

pumped central heating circuit, which activates

only when a time-clock, room thermostat and

c50°C pipe thermostat (on the domestic hot-water

side flow pipe near to the boiler), are all 'closed'.

A second electrical supply feeds a pipe thermostat

on the flow pipe to domestic water very near to the

boiler and set to close above c90°C, such that if

there is risk of boiling the central-heating pump will

always operate to dissipate heat.

Scheme 2: THERMAL STORE

A large body of water is stored at a high

temperature, to supply both taps and central

heating when needed. High and low output

phases are evened-out; heating can operate

even if the fire is out, eg, next morning.

Recommended for all uses, and always where wood is the main fuel.

In one system, a 'combined' thermal store or 'heat bank' of about 300 litre capacity is directly heated by the boiler and has an indirect

coil [1] in its highest (hottest) part to supply tap water, below which the central-heating flow is taken-off as needed.

Pump (P1) circulates hot water from the boiler to the store only when a pipe thermostat on the boiler flow pipe is above c50°C. The,

separate, central heating pump (P2) operates only when the time-clock, room

thermostat and a second c50°C thermostat responsive to temperature in the store, are

all 'closed'. A second thermostat towards the top of the store closes at c90°C to

dissipate heat if there is risk of boiling.

Extra indirect coils may be provided at [2] to accommodate a supply from a second

central-heating boiler, and at [3] to receive relatively low-grade heat from solar panels.

LINK-UP TO ANOTHER BOILER

Your stove can be linked into an oil or gas central heating system and operate

completely automatically. One method is to use a thermal store system, like Scheme 2

above, with a separate coil (for pressurised boilers) or extra direct connections (for

open-vent boilers).

Another method uses a 'neutral point manifold' where both boilers are connected to the

manifold, which is in turn connected to the hot water and radiator circuits. Suitable

devices come from

www.esse.com

and

www.systemlink.ie

.

2

Scheme 1:

Traditional 2-side system with gravity hot water.

Recommended where mineral fuels are mainly to be used

Scheme 2:

Thermal store system.

Recommended for all uses, and always where wood is the main fuel.

Outline of multiple boiler Link-Up using a neutral-point

manifold

WATER SYSTEM CONNECTIONS

Outlines of some possible installation

schemes are shown here.

In both of them:

- Possible boiling is safely accommodated

by a vent pipe leading directly to an open

feed and expansion tank.

- A c50°C low-level thermostat brings the

pumped system ‘on’ only when the fire

is hot. It prevents stored hot water from

being depleted and cold water chilling

the boiler. Vital to prevent corrosion.

- A c90°C thermostat can close to override

allother controls and operate the central

heating pump to dissipate heat if there is

a risk of boiling.

- There are time and room-temperature

controls controlling the central-heating pump.

- Hot water for taps is not separately

controlled, it may become scalding hot -

consider fitting a thermostatic mixing valve.

- An electric immersion heater is provided

for summer hot water. Temperatures are

approximate and will vary.

SCHEME 1: TRADITIONAL 2-SIDE

LINK-UP TO ANOTHER BOILER

Compact and quick to heat.

Stores hot water for taps, but

radiators will go cold if the fire

goes out. Recommended for

occasional use or where long-

burning mineral fuels are

used. One side of the boiler

feeds, by gravity circulation

alone, an indirect coil to heat a

hot-water storage cylinder and

has feed and vent connections

to a small open expansion

tank. (Gravity piping requires

careful calculation but will

generally be at least 28mm

diameter, rise continually and

have a horizontal distance from

the boiler of no more than its

vertical distance above it.)

The other side of the boiler

Your stove can be linked

into an oil or gas central

heating system and operate

completely automatically.

One method is to use a

thermal store system,

like Scheme 2 above,

with a separate coil (for

pressurised boilers) or

extra direct connections

(for open-vent boilers).

Another method uses a

‘neutral point manifold’ where

both boilers are connected

to the manifold, which is in

turn connected to the hot

water and radiator circuits.

Suitable devices come from

www.esse.com and

www.systemlink.ie.

connects to the pumped

central heating circuit, which

activates only when a time-

clock, room thermostat and

c50°C pipe thermostat (on the

domestic hot-waterside flow

pipe near to the boiler), are all

‘closed’. A second electrical

supply feeds a pipe thermostat

on the flow pipe to domestic

water very near to the boiler

and set to close above c90°C,

such that if there is risk of

boiling the central-heating

pump will always operate to

dissipate heat.

WATER SYSTEM CONNECTIONS

Outlines of some possible installation schemes are

shown here. In both of them:

●Possible boiling is safely accommodated by a

vent pipe leading directly to an open feed and

expansion tank.

●A c50°C low-level thermostat brings the pumped

system 'on' only when the fire is hot. It prevents

stored hot water from being depleted and cold

water chilling the boiler. Vital to prevent corrosion.

●A c90°C thermostat can close to override all

other controls and operate the central heating

pump to dissipate heat if there is a risk of boiling.

●There are time and room-temperature controls

controlling the central-heating pump.

●Hot water for taps is not separately controlled, it

may become scalding hot - consider fitting a

thermostatic mixing valve.

●An electric immersion heater is provided for

summer hot water.

Temperatures are approximate and will vary.

Scheme 1: TRADITIONAL 2-SIDE

Compact and quick to heat. Stores hot water

for taps, but radiators will go cold if the fire

goes out. Recommended for occasional use or

where long-burning mineral fuels are used.

One side of the boiler feeds, by gravity circulation

alone, an indirect coil to heat a hot-water storage

cylinder and has feed and vent connections to a

small open expansion tank. (Gravity piping

requires careful calculation but will generally be

at

least

28mm diameter, rise continually and have a

horizontal distance from the boiler of no more than

its vertical distance above it.)

The other side of the boiler connects to the

pumped central heating circuit, which activates

only when a time-clock, room thermostat and

c50°C pipe thermostat (on the domestic hot-water

side flow pipe near to the boiler), are all 'closed'.

A second electrical supply feeds a pipe thermostat

on the flow pipe to domestic water very near to the

boiler and set to close above c90°C, such that if

there is risk of boiling the central-heating pump will

always operate to dissipate heat.

Scheme 2: THERMAL STORE

A large body of water is stored at a high

temperature, to supply both taps and central

heating when needed. High and low output

phases are evened-out; heating can operate

even if the fire is out, eg, next morning.

Recommended for all uses, and always where wood is the main fuel.

In one system, a 'combined' thermal store or 'heat bank' of about 300 litre capacity is directly heated by the boiler and has an indirect

coil [1] in its highest (hottest) part to supply tap water, below which the central-heating flow is taken-off as needed.

Pump (P1) circulates hot water from the boiler to the store only when a pipe thermostat on the boiler flow pipe is above c50°C. The,

separate, central heating pump (P2) operates only when the time-clock, room

thermostat and a second c50°C thermostat responsive to temperature in the store, are

all 'closed'. A second thermostat towards the top of the store closes at c90°C to

dissipate heat if there is risk of boiling.

Extra indirect coils may be provided at [2] to accommodate a supply from a second

central-heating boiler, and at [3] to receive relatively low-grade heat from solar panels.

LINK-UP TO ANOTHER BOILER

Your stove can be linked into an oil or gas central heating system and operate

completely automatically. One method is to use a thermal store system, like Scheme 2

above, with a separate coil (for pressurised boilers) or extra direct connections (for

open-vent boilers).

Another method uses a 'neutral point manifold' where both boilers are connected to the

manifold, which is in turn connected to the hot water and radiator circuits. Suitable

devices come from

www.esse.com

and

www.systemlink.ie

.

2

Scheme 1:

Traditional 2-side system with gravity hot water.

Recommended where mineral fuels are mainly to be used

Scheme 2:

Thermal store system.

Recommended for all uses, and always where wood is the main fuel.

Outline of multiple boiler Link-Up using a neutral-point

manifold

SCHEME 2: THERMAL STORE

A large body of water is

stored at a high temperature,

to supply both taps and

central heating when needed.

High and low output phases

are evened-out; heating

can operate even if the fire

is out, eg, next morning.

Recommended for all uses,

and always where wood is

the main fuel. In one system,

a ‘combined’ thermal store

or ‘heat bank’ of about 300

litre capacity is directly

heated by the boiler and

has an indirect coil [1] in

its highest (hottest) part

to supply tap water, below

which the central-heating

flow is taken-off as needed.

Pump (P1) circulates hot

water from the boiler to

the store only when a pipe

thermostat on the boiler

flow pipe is above c50°C.

The separate, central

heating pump (P2) operates

only when the time-clock,

room thermostat and a

second c50°C thermostat

responsive to temperature in

the store, areall ‘closed’.

A second thermostat towards

the top of the store closes

at c90°C to dissipate heat

if there is risk of boiling.

Extra indirect coils may

be provided at [2] to

accommodate a supply from

a second central-heating

boiler, and at [3] to receive

relatively low-grade heat

from solar panels.

(about 90°C) to override

controls and run the

heating circuit to dissipate

heat if there is a risk of

boiling. Stored hot water

for taps is not controlled,

but accumulates during

normal operation, especially

during periods while central

heating is not required.

BOILER STOVE CENTRAL HEATING SYSTEMS

This is a rough guide to specifying and fitting central heating using a solid fuel boiler stove with thermostatic control. It doesn't cover

every detail, which will need to be determined on-site by a skilled heating engineer.

'Wet' solid fuel central heating systems use the same types of pipework (including microbore, plastic) and heat emitters (radiators,

underfloor, etc), as other fuels and they can likewise come on in the morning, go off at night and regulate themselves. Systems must...

1: CONTROL THE HEATING SYSTEM.

Stove boilers control their own water temperature by an internal thermostat, so controls

such as time clocks and thermostats regulate flow through the heating circuit, not the boiler.

2: GUARD AGAINST CONDENSATION!

Solid fuels contain water which can condense on cool boiler faces to cause VERY rapid corrosion

and failure. Use

very

dry fuel and

always

fit a device such as a low-level thermostat to minimise cool water circulating through the boiler.

2: ALLOW FOR EXCESS HEAT.

The fire can close down automatically, but it can't

completely

stop combustion and output will vary

considerably during a fuelling cycle. There must be some infallible means of dissipating, and preferably storing, surplus heat, for instance a

hot water cylinder or a thermal store and always a system to run the central-heating pump if there is risk of boiling. Should thermostat and

pump fail together, there must be infallible provision to cool the system, or allow it to boil, for instance through an open vent. (The old-

fashioned idea of deliberately wasting heat through a permanent "heat leak" radiator not only throws heat away, it just will not suffice with

powerful modern stoves.)

HEAT REQUIREMENT

GET THE RIGHT SIZE HEATERS.

Guesswork won't do. A preliminary estimate of heat

requirement for each room can be got from the table here.

Example

: A room 6m x 5m x 2.8m

has volume of 84m³. If it was a ground floor room in the corner of a two-storey house, in

which the adjacent rooms and the one above were also heated, then 2 unheated outside

walls + 1 outside floor = 3 unheated faces. If moderately insulated then the factor in the table

is 40 Watts per m³, so 84m³ x 40 = 3360 Watts, or 3.36kW. A radiator, or radiators, emitting

at least 3.36kW should be specified.

Don't forget that, with boiler stoves, the room output and water output go up and down

together - turn the central heating down, and the whole stove goes cooler. It is usually wise to

fit a radiator (with thermostatic valve) in the fireplace room.

The actual value varies with the shape, exposure, draughtiness and temperatures. For larger

installations or whole-house heating, use the more accurate 'U-Value method - an online

heat-need calculator is available at

www.soliftec.com

.

APPROXIMATE HEAT REQUIREMENT OF ROOMS

Watts

per

Cubic Metre

Number of unheated faces

1

2

3

4

5

6

No effective insulation

eg: all-glass rooms with single glazing, barns, workshops, tents

120

132

145 158 170 183

Poor insulation

eg; single glazing, little loft insulation, uninsulated cavity walls, draughts

62

70

78

86

94 102

Moderate insulation

eg: thick solid walls, some loft insulation, some draught-proofing

31

35

40

44

48

53

Good Insulation

eg: some wall insulation, thick loft insulation, double glazing, draught-proofing

21

24

27

31

34

37

Best insulation

eg: properties built to 2008 UK standards

16

18

20

22

24

26

Watts (W) per cubic metre

CONTROLS

Your stove has a built-in

mechanical thermostat to

regulate

its

water

temperature. A tiny vial of oil

is fitted in the boiler. As the

boiler water gets hotter, the

oil expands along a fine tube,

moves a bellow outward,

moving an arm, which closes

off air to the fuel and so

slows combustion. So, if the timeclock or room thermostat determines

that no heat is needed, it stops the circulating pump; without water

circulation the boiler begins to get too hot, the oil expands, shuts off

air and the fire dies down. If there is demand for heat, for instance in

the morning, the pump comes on, colder water enters the boiler, the

air-flap opens and the fire blazes up.

The control dial on the stove does not directly turn the stove up and

down, it sets the water temperature at which the thermostat will begin

to shut the fire down.

We recommend a control system regulating the central-heating pump through (1) a single-channel time clock, (2) a centrally-located

room thermostat (not in the stove room) and (3) thermostatic radiator valves on all but one radiator. A low-level (about 50°C) pipe

thermostat to prevent pumped circulation of cool water (which can cause condensation, rust, and deplete stored hot water) and a high

level one (about 90°C) to override controls and run the heating circuit to dissipate heat if there is a risk of boiling. Stored hot water for

taps is not controlled, but accumulates during normal operation, especially during periods while central heating is not required.

1

Copyright © and UK Design Right, Glyn Hughes 2006-2013.

'Teddington' thermostat

(Normal cold '0' setting - about 7mm open)

Typical wiring layout through connector block (return dotted)

Room and boiler outputs vary together

BOILER STOVE CENTRAL HEATING SYSTEMS

This is a rough guide to specifying and fitting central heating using a solid fuel boiler stove with thermostatic control. It doesn't cover

every detail, which will need to be determined on-site by a skilled heating engineer.

'Wet' solid fuel central heating systems use the same types of pipework (including microbore, plastic) and heat emitters (radiators,

underfloor, etc), as other fuels and they can likewise come on in the morning, go off at night and regulate themselves. Systems must...

1: CONTROL THE HEATING SYSTEM.

Stove boilers control their own water temperature by an internal thermostat, so controls

such as time clocks and thermostats regulate flow through the heating circuit, not the boiler.

2: GUARD AGAINST CONDENSATION!

Solid fuels contain water which can condense on cool boiler faces to cause VERY rapid corrosion

and failure. Use

very

dry fuel and

always

fit a device such as a low-level thermostat to minimise cool water circulating through the boiler.

2: ALLOW FOR EXCESS HEAT.

The fire can close down automatically, but it can't

completely

stop combustion and output will vary

considerably during a fuelling cycle. There must be some infallible means of dissipating, and preferably storing, surplus heat, for instance a

hot water cylinder or a thermal store and always a system to run the central-heating pump if there is risk of boiling. Should thermostat and

pump fail together, there must be infallible provision to cool the system, or allow it to boil, for instance through an open vent. (The old-

fashioned idea of deliberately wasting heat through a permanent "heat leak" radiator not only throws heat away, it just will not suffice with

powerful modern stoves.)

HEAT REQUIREMENT

GET THE RIGHT SIZE HEATERS.

Guesswork won't do. A preliminary estimate of heat

requirement for each room can be got from the table here.

Example

: A room 6m x 5m x 2.8m

has volume of 84m³. If it was a ground floor room in the corner of a two-storey house, in

which the adjacent rooms and the one above were also heated, then 2 unheated outside

walls + 1 outside floor = 3 unheated faces. If moderately insulated then the factor in the table

is 40 Watts per m³, so 84m³ x 40 = 3360 Watts, or 3.36kW. A radiator, or radiators, emitting

at least 3.36kW should be specified.

Don't forget that, with boiler stoves, the room output and water output go up and down

together - turn the central heating down, and the whole stove goes cooler. It is

usually wise to

fit a radiator (with thermostatic valve) in the fireplace room.

The actual value varies with the shape, exposure, draughtiness and temperatures. For larger

installations or whole-house heating, use the more accurate 'U-Value method - an online

heat-need calculator is available at

www.soliftec.com

.

APPROXIMATE HEAT REQUIREMENT OF ROOMS

Watts

per

Cubic Metre

Number of unheated faces

1

2

3

4

5

6

No effective insulation

eg: all-glass rooms with single glazing, barns, workshops, tents

120

132

145 158 170 183

Poor insulation

eg; single glazing, little loft insulation, uninsulated cavity walls, draughts

62

70

78

86

94 102

Moderate insulation

eg: thick solid walls, some loft insulation, some draught-proofing

31

35

40

44

48

53

Good Insulation

eg: some wall insulation, thick loft insulation, double glazing, draught-proofing

21

24

27

31

34

37

Best insulation

eg: properties built to 2008 UK standards

16

18

20

22

24

26

Watts (W) per cubic metre

CONTROLS

Your stove has a built-in

mechanical thermostat to

regulate

its

water

temperature. A tiny vial of oil

is fitted in the boiler. As the

boiler water gets hotter, the

oil expands along a fine tube,

moves a bellow outward,

moving an arm, which closes

off air to the fuel and so

slows combustion. So, if the timeclock or room thermostat determines

that no heat is needed, it stops the circulating pump; without water

circulation the boiler begins to get too hot, the oil expands, shuts off

air and the fire dies down. If there is demand for heat, for instance in

the morning, the pump comes on, colder water enters the boiler, the

air-flap opens and the fire blazes up.

The control dial on the stove does not directly turn the stove up and

down, it sets the water temperature at which the thermostat will begin

to shut the fire down.

We recommend a control system regulating the central-heating pump through (1) a single-channel time clock, (2) a centrally-located

room thermostat (not in the stove room) and (3) thermostatic radiator valves on all but one radiator. A low-level (about 50°C) pipe

thermostat to prevent pumped circulation of cool water (which can cause condensation, rust, and deplete stored hot water) and a high

level one (about 90°C) to override controls and run the heating circuit to dissipate heat if there is a risk of boiling. Stored hot water for

taps is not controlled, but accumulates during normal operation, especially during periods while central heating is not required.

1

Copyright © and UK Design Right, Glyn Hughes 2006-2013.

'Teddington' thermostat

(Normal cold '0' setting - about 7mm open)

Typical wiring layout through connector block (return dotted)

Room and boiler outputs vary together

Typical wiring layout through

connector block (return dotted)

‘Teddington’ thermostat (Normal

cold ‘0’ setting - about 7mm open)

Scheme 1: Traditional 2-side system with gravity hot water.

Recommended where mineral fuels are mainly to be used

Scheme 2: Thermal store system. Recommended for

all uses, and always where wood is the main fuel.

Outline of multiple boiler Link-Up using

a neutral-point manifold