MORTEX

PRODUCTS

INC

FORT

WORTH,

TX

76106

Page

9

15.

Reinstall the blower assembly and secure the assembly

using the screws that were removed in step 5.

16.

Reinstall the control box cover and secure it to the control

box with the screws that were removed in step 4.

17.

Reinstall the lower access door on the furnace.

18.

Reinstall the upper access door on the front of the

evaporator coil compartment.

19.

Follow the instructions exactly as shown in start Up and

Shutdown Section in this manual to properly start Up this

appliance.

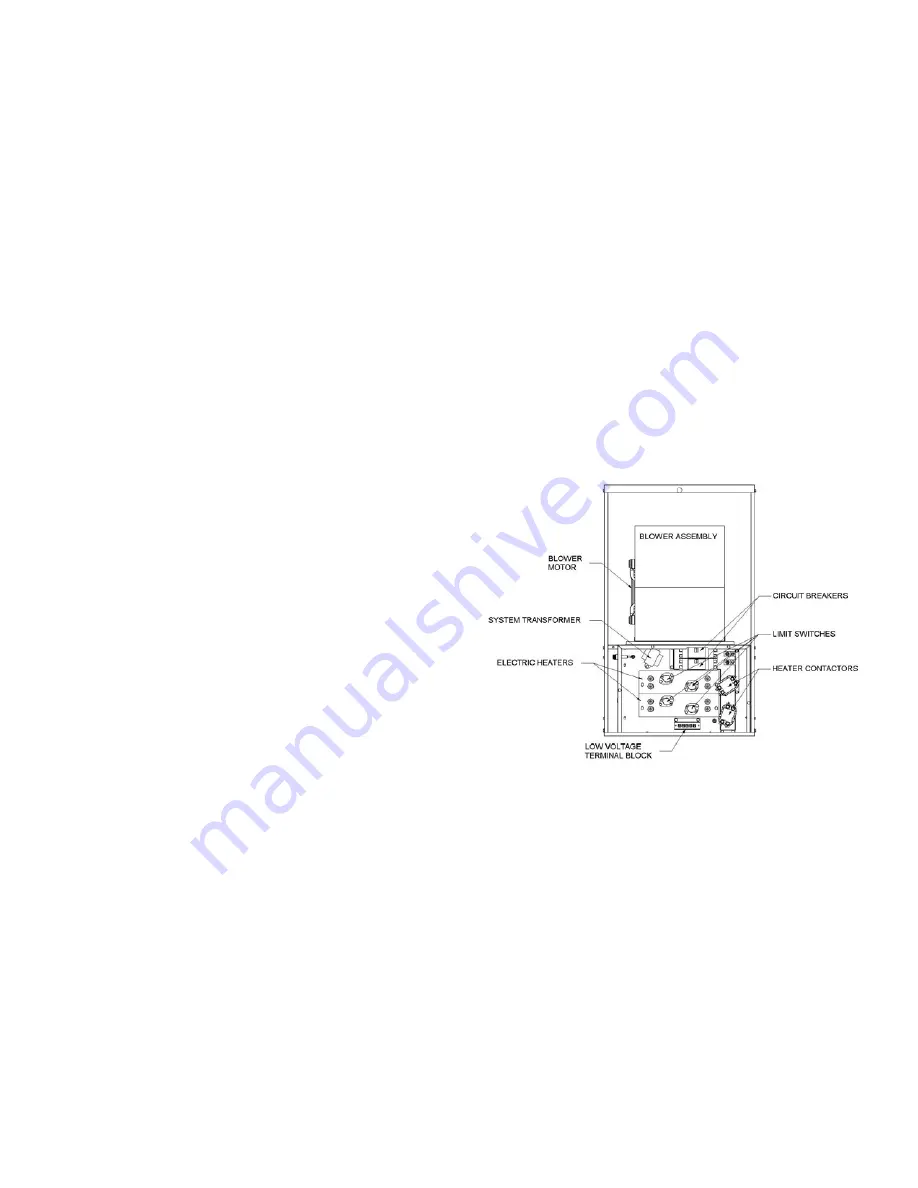

SECTION III: FURNACE CONTROLS

This section discusses the furnace controls and how they

operate. Refer to Figure 9 for component locations.

1.

The Limit Controls

– Each electric heater element has a

limit control directly in front of it to sense overheating of

the element and opens if the temperature gets above the

set point of the limit control.

2.

The Heater Contactors

– The electric heater contactors

simply turn the heater elements on and off. The contactors

are controlled by the thermostat. On a call for heat 24

VAC is sent to the contactor 24 VAC coil energizing the

contactor. When the call for heat has been satisfied the 24

VAC is removed from the contactors 24 VAC coil de-

energizing the contactors.

3.

Cooling Time Delay

– The cooling indoor fan on / off

delay is factory programmed in the indoor fan motor

software and is non-adjustable.

4.

Heating Time Delay

– The heating indoor fan on / off

delay is factory programmed in the indoor fan motor

software and is non-adjustable.

5.

Circuit breakers

– The circuit breakers are designed as

over-current protection for the electric heaters only. The

circuit breakers MUST NEVER be used for over-current

protection for the transformer, 24 VAC circuit, or the

blower motor.

6.

3 Amp Fuse

– This fuse is used for over-current

protection of the 24 VAC circuit.

7.

Transformer

– The transformer is used to step down

voltage from 240 VAC to 24 VAC. The transformer

provides the required 24 VAC for the system control

circuit.

8.

Thermostat “G” Circuit

– The thermostat “G” circuit is

used for constant circulation only. When 24 VAC is

placed on the thermostat “G” circuit the 24 vac is sent to

the indoor fan motor where it will operate around 200

CFM. This is not enough air flow for heating or cooling

operation.

9.

Thermostat “Y” Circuit

– The thermostat “Y” circuit is

used for cooling or high speed indoor fan operation.

When 24 VAC is placed on the thermostat “Y” circuit the

24 vac is sent to the indoor fan motor where it will

operate around at high speed. The compressor contactor is

also connected to this terminal.

10.

Thermostat “W” Circuit

– The thermostat “W” circuit is

used for the heating indoor fan blower operation on the

Med-low or Medium speed. When 24 VAC is placed on

the thermostat “W” circuit the 24 vac is sent to the indoor

fan motor where it will operate at the selected speed

required for heating after the ON delay has been

completed.

SECTION IV: SEQUENCE OF OPERATION

Continuous Blower

The thermostat has a manual fan switch that can be moved to

the “

On”

position or it can be programmed for

continuous

fan

operation. This setting causes the thermostat to complete the

circuit between “R” and “G” terminals causing the blower

motor to start the ON time delay. Once the time delay has

completed the motor will start. When the thermostat “G”

circuit has been de-energized the motor will start the OFF

delay. The motor will turn off when the off delay has been

completed.

The indoor blower will operate continuously until the fan

switch on the thermostat has been switched from ON to

AUTO. The AUTO position will allow the blower motor to

operate only when there is a call for heat or cooling. The

motor will remain in standby mode at all other times.

Figure 9: Component Locations

Intermittent Blower - Cooling

The thermostat has a manual fan switch that can be moved to

the “

Auto”

position or it can be programmed for

auto

fan

operation. When the thermostat calls for cooling, a circuit is

completed between the “R” and “Y” Terminals. The indoor

fan motor is energized from the “Y” terminal on the

thermostat causing the indoor fan motor to start after the ON

delay has expired. The motor will start on the selected speed

tap that is connected to the “Y” terminal. When the call for

cooling is complete the blower motor will start the off delay.

Once the off delay has expired the motor will de-energize.

The blower is now in the standby mode waiting for the next

cooling cycle

The Heating Cycle

When the thermostat is in the HEAT mode and the fan switch

on the thermostat is set to AUTO. The call for heat closes the

thermostat circuit between the “R” and “W” terminals. 24

VAC is sent from the “W” thermostat terminal, through the