MORTEX

PRODUCTS

INC

FORT

WORTH,

TX

76106

Page

11

SECTION V: TROUBLE SHOOTING

The following checks should be made before trouble shooting

the furnace controls for a no heat issue.

1.

Check all of the circuit breakers. Make sure they are

turned to the “ON” position and have not tripped.

2.

Check all fuses, especially the 3 amp fuse on the top right

side of the control box. If the fuse is blown, check the

wiring with an OHM meter for a short to ground. If

shorted, repair the short, and then replace the fuse.

3.

Check any electrical switches that are external to the

furnace to make sure they are turned on.

4.

Check all wiring connections, especially on any of the

components, to ensure they are securely fastened.

If you have 240 VAC coming out of the control box circuit

breakers and you have 24 VAC between the load side if the 3

amp fuse and ground, then continue on through the rest of the

checks.

X-13 Motor Check – Heating Mode

1.

If the motor is not running, check for 240 VAC and 24

VAC at the motor terminals. If the 240 VAC and 24 VAC

is present at the motor terminals but the motor is not

operating, then replace the motor. Refer to Figure 12 and

Table 1 for terminal locations and definitions.

A.

If 240 VAC is not present at the motor check for a

broken wire between the circuit breaker and the

motor.

B.

If 240 VAC is present at the motor terminals continue

to the next check.

2.

If 24 VAC is not present at the motor check for 24 VAC

across the heater relay coil.

A.

If 24 VAC is present at the heater relay coil, the wire

going to the motor is bad and needs to be replaced.

B.

If 24 VAC is not present at the heater relay coil check

the thermostat “W” circuit wire connections and the

thermostat.

X-13 Motor Check – Cooling Mode

1.

If the motor is not running, check for 240 VAC and 24

VAC at the motor terminals.

A.

If the 240 VAC and 24 VAC is present at the motor

terminals but the motor is not operating, then replace

the motor. Refer to Figure 12 and Table 1 for

terminal locations and definitions.

B.

If 240 VAC is not present at the motor check for a

broken wire between the circuit breaker number one

and the motor.

C.

If 240 VAC is present at the motor terminals continue

to the next check.

2.

If 24 VAC is not present at the motor speed tap terminals;

check for 24 VAC at terminal #1 on the TDR

A.

If 24 VAC is present at terminal #1, the wire going

to the motor is bad and needs to be replaced.

B.

If 24 VAC is not present at terminal #1 check

terminal #3.

C.

If 24 VAC is present at the terminal #3 replace the

TDR.

1

3

LOAD

1.5 AMP

MAX

CUT WIRE FOR 120/240 VAC

.4

15

30 SECONDS

MADE IN

THE USA

ICM

HMPS00C2X30

DELAY ON

MAKE

TIMER

CONTROLS

INPUT

19-240

VAC

Figure 11: Time Delay Relay (TDR) Terminals

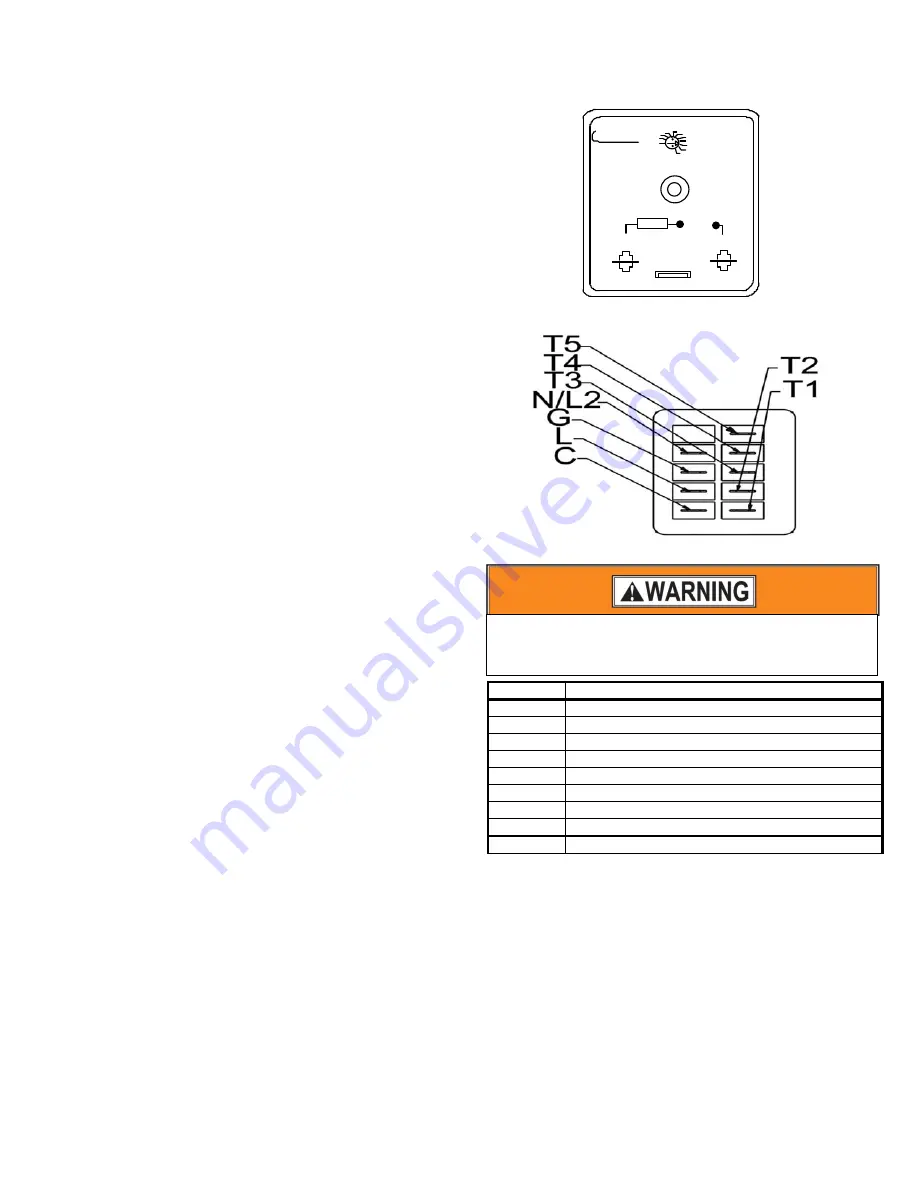

Figure 12: X-13 Motor Terminals

Terminal

Connection

C

Speed

Tap

Common

‐

24

VAC

Common

L

Supply

Voltage

to

Motor

‐

240

VAC

Line

1

G

Ground

Connection

N

Supply

Voltage

to

Motor

‐

240

VAC

Line

2

1

Low

Speed

Tap

‐

24

VAC

2

Med

‐

Low

Speed

Tap

‐

24

VAC

3

Medium

Speed

Tap

‐

24

VAC

4

Med

‐

High

Speed

Tap

‐

24

VAC

5

High

Speed

Tap

‐

24

VAC

Table 1: X-13 Motor Terminal Connections

Heater Element Is Not On

Check for 240 VAC between each of the heater elements. If

240 VAC is present, check the current draw on each heater. If

there is 200 – 250 VAC across the heaters but a heater is not

drawing the proper current or is showing almost no current

draw check the limit for that heater. If the limit is good but

there still is no current flow then, check to see if the heater is

defective.

The heater amps are as follows:

4 kW Heater = 16.7 amps

5 kW Heater = 20.8 amps

6 kW Heater = 25.0 amps

The heater design is as follows:

To avoid personal injury or property damage, make certain

that the motor leads cannot come into contact with non-

insulated metal components of the unit.