9

Mortex Products, Inc. / FT. WORTH, TX 76106

G17 / G18 Installation Instructions

Printed 04/04

8

Mortex Products, Inc. / FT. WORTH, TX 76106

G17 / G18 Installation Instructions

Printed 04/04

INSTALLATION INSTRUCTIONS

CUTTING ROOF JACK OPENING

A proper installation of the roof jack requires that openings

in roof and ceiling be on the same vertical centerline as the

furnace flue collar. See FIG. I

FIG. I - ROOF CUT-OUT

Mark the center point on the ceiling and scribe a 4” radius

(8” diameter) around this mark. If furnace is in place during

this step, cover the furnace and flue opening to prevent

debris from entering flue.

INSTALLING ROOF JACK

The roof jack body should be secured to the furnace before

the roof flashing is secured to the roof.

1. Insert roof jack body into opening in the roof.

2. From above, center the roof jack body aligning with

the furnace collar.

3. From inside the home, pull down 4-3/16” D flue

pipe seating the pipe fully and firmly over the

furnace flue collar.

4. Next pull down the 7” D combustion air pipe seating

it over the mating furnace collar. Rotate the

combustion air pipe lining up to the screw hole on the

7” furnace collar.

5. Check and make sure the combustion air pipe is fully

seated. Then drive a #10 sheet metal screw attaching

pipe firmly to furnace collar.

6. Install optional ceiling trim ring, 90-TRM-RNG

7. On the roof, caulk liberally under the roof jack

flashing.

8. Drive nails or screws through the flashing onto the

roof surface about 1- 1 _ inches apart. Caulk again

to ensure a leak tight joint.

9. Install roof jack crown and fasten to roof jack body

with three (3) screws (provided) using pre-punched

holes.

INSTALLATION IN SNOW REGIONS

When the combustion air inlet to the roof jack is blocked

with snow, the furnace will not operate properly due to the

depleted combustion air supply.

Therefore, if the furnace will be located in regions where

snow accumulation on the roof exceeds 7” or in H.U.D.

Snow Load Zones, a roof jack extension- Part No. 90-

0UTXT16-AL- is recommended.

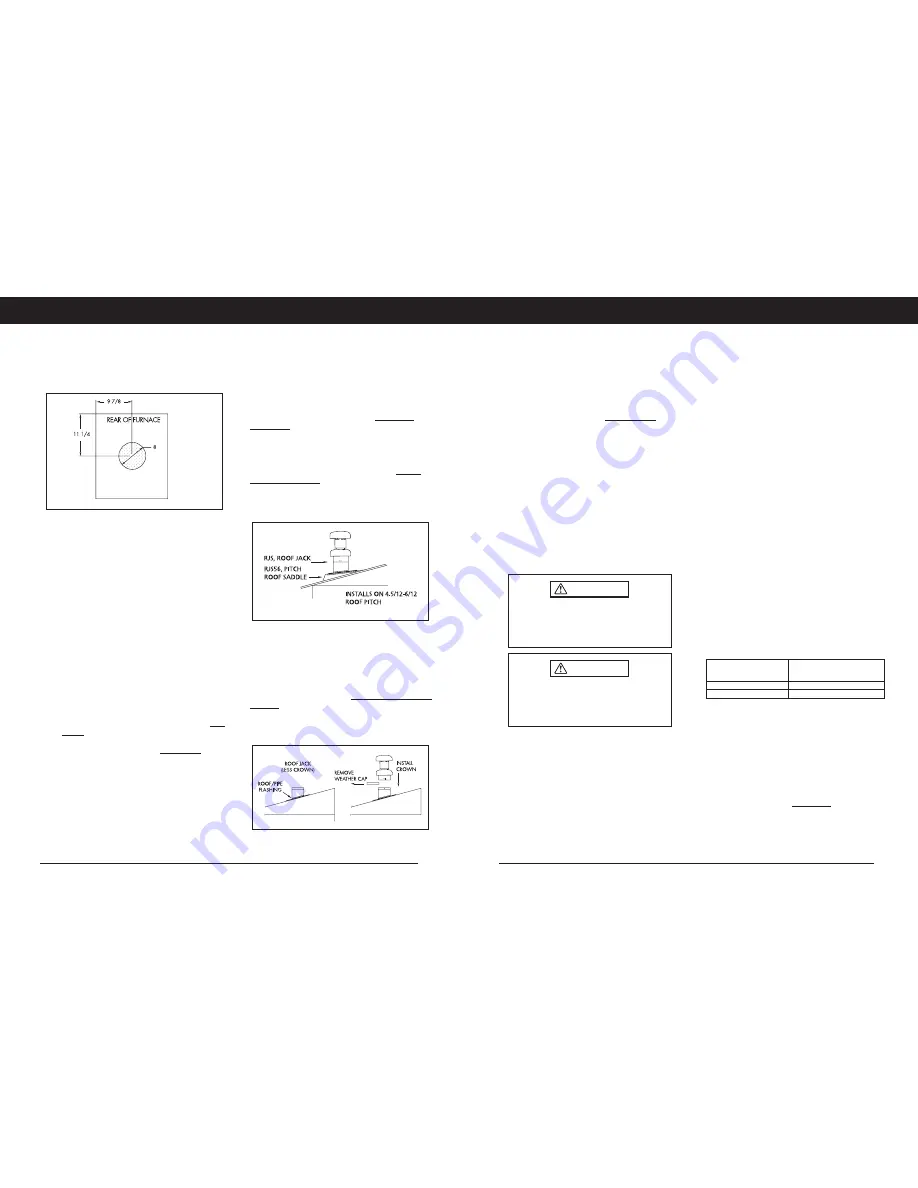

ROOF JACK ON HI-PITCH ROOF

To install the RJS (3/12) Series Roof Jack on roofs which

have a slope between 4.5/12 - 6/12, install a Part No.

90-RJS56 Roof Saddle, Fig. J. The combined assembly of

the RJS Roof Jack and Roof Saddle will conform to the

higher roof pitch. If roof pitch is greater than 6/12, field

fabricate a suitable adapter, or consult with factory.

FIG. J - 90-RJS56 ROOF SADDLE, HI PITCH ROOF

TRANSIT ROOF JACK - MODE

RJF and RJS Roof Jacks feature a removable top crown. The

crown is normally installed at the factory. If road clearance

for the home requires that vent caps or crowns remain

uninstalled for road clearance, a Transit Mode Kit, Part No.

90-RJTRC is available. The kit, when used, allows for home

shipment with the crown shipped inside the home. The kit

includes a weather cap and four (4) warning tags.

FIG. K - 90-RJTRC TRANSIT MODE INSTALLATION

INSTALL TRANSIT ROOF JACK

AT MANUFACTURED HOME FACTORY

1. Roof Jack body (less crown) installed per instructions

in this manual.

2. Install weather cap from 90-RJTRC kit on RJF or RJS

upper body.

3. The 3 warning tags supplied must be attached as

follows:

• To homes gas line connection point

• To furnace gas control valve

• To furnace wall thermostat

4. Upper crown, in original carton must be stored in a

prominent location inside the home until crown

installation is made at site location.

AT MANUFACTURED HOME SITE

5. The transit weather cap is removed and

6. 90-RJCRWN-AL crown installed per these instructions.

See FIG K. Make sure crown engages RJ-body pipes

above the roof and crown is secured with 3 sheet

metal screws.

7. Transit system warning tags are discarded.

CONNECT POWER SUPPLY

1. Remove the furnace control panel cover.

2. Insert 115 V wiring through a strain relief bushing on

the left side of the furnace.

3. Connect the HOT wire to the BLACK pigtail lead;

connect the NEUTRAL wire to the WHITE pigtail lead.

Secure the connections with suitable wire nuts and

wrap with electrical tape. Refer to Pgs. 11 thru 13 and

one of the following Fig’s L,M,N,O,P or Q to select the

proper wiring diagram for connections

4. Connect the GROUND wire to a grounding screw in

the control panel.

5. Reinstall and secure the control panel cover

with screws.

WALL THERMOSTAT

The location of the wall thermostat is important, as it must

sense the desired temperature of the entire conditioned

space. Choose a location 4-5 feet above the floor,

preferably on an inside wall in an area with good air

circulation. Stay away from lamps and air registers and do

not install behind a door. Choose a location where the

temperature will be reasonably representative of other living

areas the thermostat is controlling.

CONNECT THERMOSTAT WIRES

When installing a furnace with a cooling coil compartment,

use of a five-conductor thermostat cable is recommended.

This will allow easy installation of an air conditioning sys-

tem at a later date.

1. Insert 24V wires through the small plastic bushing on

the left side of the furnace.

2. Connect low voltage wires to the color coded low

voltage pigtails at top of the control panel.

3. Connect low voltage wires to the wall thermostat.

NOTE: The use of 18-gauge wire is highly recommended to

carry the thermostat load. Use of smaller conductors risks

operational problems caused by loose or broken conductors

or wire that is too small to carry the load. Any such

problems are the responsibility of the installer.

With conductors smaller than 18 gauge, observe the

following guidelines.

Thermostat wire length

-furnace to thermostat-

Thermostat wire gauge

0-45 feet

22

0-70 feet

20

GAS PIPING

Supply piping must be sized in accordance with

recommendations found in National Fuel Gas Code ANSI

Z223.1/NFPA-54. In addition materials used in manufactured

homes must comply with requirements contained in HUD

Title 24, Section 3280.705 as well as A119.1 and A119.2

for recreational vehicles.

See chart in this manual for minimum sizes for NAT and LP

pipe and tubing serving the furnace only.

NOTE: The gas inlet on the gas control valve is 1/2-14NPT.

The gas line may be installed through the bottom casing or

on left or right side of furnace.

WARNING

Any attempt to operate furnace before replacing

transit-mode Weather Cap with Roof Jack Crown

may result in hazard of fire, explosion or

asphyxiation.

WARNING

To avoid electric shock, personal injury, or death,

turn off the power at the disconnect or the main

service panel before making any electrical

connections.