USE

WELDING DIGITAL CONTROL

M

33.

3

© MOSA

REV.1-01/08

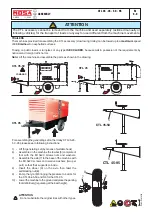

WIRE FEEDER CONNECTED WITH REMOTE

CONTROL CONNECTOR

Wire feeder connection

Connect the wire feeder to the welder with the

welder turned off:

-Welding cable between the machine’s (9) welding

plug (+) and the wire feeder.

-Welding cable between the machine’s (10) welding

plug (-) and the piece to be welded.

-Control/power cable between the machine’s

connector (X1) and the corresponding connector

on the wire feeder.

Start the machine welder

The “ON” LED will be off and will turn on only when

there is voltage at the welding plugs (and therefore

at the wire).

The voltage is only present when the welding torch

button is pressed.

The setting of the welding voltage is done using the

knob on the wire feeder.

The adjusting knob on the welder is automatically

inhibited.

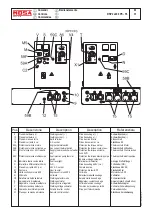

You can use the wire feeder only by respecting

the pin configuration as shown on the below

mentioned table.

WARNING

A (

electric ground

)

B

C (5 V d.c.)

D

E

F (5 V d.c.)

G

H (welding ground)

I (44 - 48V a.c.)

J (44 - 48V a.c.)

DESCRIPTION

To potentiometer RC1 "terminal

a"

To potentiometer RC1"central b"

To potentiometer RC1 "terminal

c"

short circuit with contact "C"

NAME OF

CONTACT

To switch "Polarity Inverter"

(Close for negative polarity)

Return from switch on CV welding

gun, 1-phase (44 - 48V a.c.)

Welding ground for d.c. voltmeter

on wire feeder

Voltage supply for wire feeder

CV

CC

STAND-BY

CONTACT

STARTING

REMOTE

CONTROL

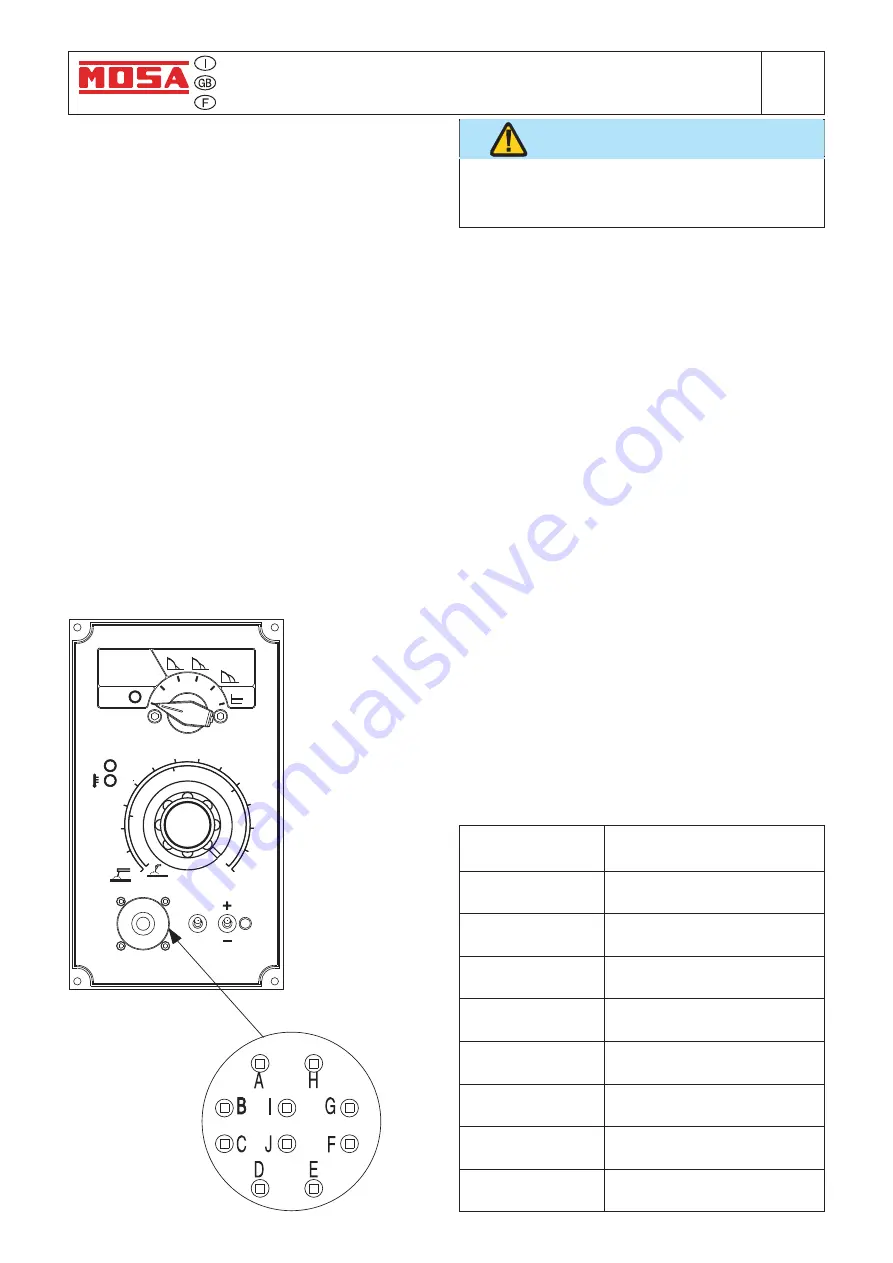

70

20

25

40

100

WELDING DIGITAL CONTROL

130

160

190

220

250

280

310

340

370

400A

36V

16

10

30

ON

POLARITY

CURRENT CC

MAX

50%

INVERTER

RANGE

TIG

ARC FORCE

CELLULOSE 1

CELLULOSE 2

CC-STICK

CV-WIRE

11/10/04 M33_WDC_GB

“WIRE FEEDER connected without remote

control connector”

Welding voltage is always present on welding

sockets and also VRD is active.

-Welding cable between the machine’s (9) welding

plug (+) and the wire feeder.

-Welding cable between the machine’s (10) welding

plug (-) and the piece to be welded.

The setting of the welding voltage is done by using

the knob on the front panel.

Summary of Contents for DSP 2x400 PS-PL

Page 38: ...DSP 2x400 PSX REV 0 11 05 M 53 Dimensioni Abmessungen Dimension 18 11 05 88412 I...

Page 42: ...DSP 2x400 PS PL REV 0 11 05 M 61 2 Stromlaufplan 28 11 05 78413 D...

Page 43: ...DSP 2x400 PS PL REV 1 02 11 M 61 3 Stromlaufplan 28 11 05 78413 D...

Page 44: ...DSP 2x400 PS PL REV 1 02 11 M 61 4 Stromlaufplan 28 11 05 78413 D...

Page 45: ...DSP 2x400 PS PL REV 1 02 11 M 61 5 Stromlaufplan 28 11 05 78413 D...

Page 46: ...DSP 2x400 PS PL REV 1 02 11 M 61 6 Stromlaufplan 28 11 05 78413 D...