MAINTENANCE

M

43

© MOSA

REV.0-06/10

NOTE

By maintenance at care of the utilizer we intend all the

operatios concerning the verification of mechanical

parts, electrical parts and of the fluids subject to use or

consumption during the normal operation of the machine.

For what concerns the fluids we must consider as main

-

tenance even the periodical change and or the refills

eventually necessary.

Maintenance operations also include machine cleaning

operations when carried out on a periodic basis outside

of the normal work cycle.

The repairs

cannot be considered

among the main-

tenance activities, i.e. the replacement of parts subject

to occasional damages and the replacement of electric

and mechanic components consumed in normal use, by

the Assistance Authorized Center as well as by MOSA.

The replacement of tires (for machines equipped with

trolleys) must be considered as repair since it is not de

-

livered as standard equipment any lifting system.

The periodic maintenance should be performed accor

-

ding to the schedule shown in the engine manual. An

optional hour counter (M) is available to simplify the

determination of the working hours.

THE ENGINE PROTECTION NOT WORK WHEN THE

OIL IS OF LOW QUALITY BECAUSE NOT CHARGED

REGULARLY AT INTERVALS AS PRESCRIBED IN THE

OWNER’S ENGINE MANUAL.

NOTE

!

IMPORTANT

In the maintenance operations avoid that

polluting substances, liquids, exhausted oils,

etc. bring damage to people or things or can

cause negative effects to surroindings, health

or safety respecting completely the laws and/

or dispositions in force in the place.

!

WARNING

!

Have

qualified

personnel do maintenance and troubleshooting work.

l

Stop the engine before doing any work inside the machine. If for

any reason the machine must be operated while working inside,

pay

attention

moving parts, hot parts (exhaust manifold and muffler,

etc.) electrical parts which may be unprotected when the machine

is open.

l

Remove guards only when necessary to perform maintenance,

and replace them when the maintenance requiring their removal is

complete.

l

Use suitable tools and clothes

.

l

Do not modify the components if not authorized.

- See pag. M1.1

-

HOT surface

can

hurt you

MOVING

PARTS

can injure

05/09/05 M43GB

ENGINE and ALTERNATOR

PLEASE REFER TO THE SPECIFIC MANUALS

PROVIDED.

Every engine and alternator manufacturer has

maintenance intervals and specific checks for each

model: it is necessary to consult the specific engine or

alternator USER AND MAINTENANCE manual.

VENTILATION

Make certain there are no obstructions (rags, leaves or

other) in the air inlet and outlet openings on the machine,

alternator and motor.

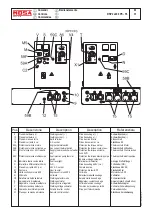

ELECTRICAL PANELS

Check condition of cables and connections daily.

Clean periodically using a vacuum cleaner,

DO NOT USE

COMPRESSED AIR.

DECALS AND LABELS

All warning and decals should be checked once a year

and

replaced

if missing or unreadable.

STRENUOUS OPERATING CONDITIONS

Under extreme operating conditions (frequent stops

and starts, dusty environment, cold weather,extended

periods of no load operation, fuel with over 0.5% sulphur

content) do maintenance more frequently.

BATTERY WITHOUT MAINTENANCE

DO NOT OPEN THE BATTERY

The battery is charged automatically from the battery

charger circuit suppplied with the engine.

Check the state of the battery from the colour of the

warning light which is in the upper part.

- Green colour: battery OK

- Black colour: battery to be recharged

- White colour: battery to be replaced

Summary of Contents for DSP 2x400 PS-PL

Page 38: ...DSP 2x400 PSX REV 0 11 05 M 53 Dimensioni Abmessungen Dimension 18 11 05 88412 I...

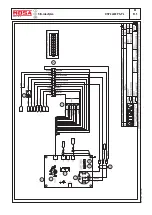

Page 42: ...DSP 2x400 PS PL REV 0 11 05 M 61 2 Stromlaufplan 28 11 05 78413 D...

Page 43: ...DSP 2x400 PS PL REV 1 02 11 M 61 3 Stromlaufplan 28 11 05 78413 D...

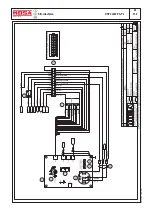

Page 44: ...DSP 2x400 PS PL REV 1 02 11 M 61 4 Stromlaufplan 28 11 05 78413 D...

Page 45: ...DSP 2x400 PS PL REV 1 02 11 M 61 5 Stromlaufplan 28 11 05 78413 D...

Page 46: ...DSP 2x400 PS PL REV 1 02 11 M 61 6 Stromlaufplan 28 11 05 78413 D...