General precautions when handling the machine.

To limit the dangers involved in moving a generating set,

it is important to carefully follow the guideline set out

below:

• Transportation must always take place with the en-

gine off and electrical cables and starting battery di-

sconnected and fuel tank empty.

• Particular attention must be paid to SKID version ge-

nerating sets (without canopy) that have very delicate

parts unprotected from bumps (injection pump, speed

regulator, radiator, electrical panel connections and

instrumentation).

• Generating sets must be protected from bad weather

during transport: the units must be entirely covered,

especially the electrical parts (alternator and control

panel).

• Some engine parts retain heat even after it has been

shut off: therefore it is necessary to wait for the engi-

ne to cool before covering it to avoid the risk of fire.

• Clear the moving zone of all possible obstacles and

from all unnecessary personnel.

• Use properly sized lifting equipment regularly submit-

ted to major overhaul by an authorized organisation.

It is prohibited to fasten objects or accessories on the

generating set baseframe that may modify weight

and center of gravity and may cause movements un-

foreseen by the lifting eyes.

• Do not subject the generating set and lifting equip-

ment to abrupt or undulating movements that pass on

stress dynamics to the structure.

• Do not lift the generating set higher than what is ab-

solutely necessary.

• Transportation of separate manual or automatic con-

trol panels must be carried out very carefully in order

to avoid damage to the equipment contained inside

the panel and to the instruments on the front.

• To access the hook points on the top of the unit, use

approved ladders only or support from another opera-

tor: climb the ladder using non-skid shoes.

ATTENTION

When moving/lifting a genset it is imperative to be

extremely careful. All moving operations must be

carried out be qualified persons.

Due to the weight and encumbrance of the genset,

an error while moving/lifting the unit may cause

serious damage to it or surrounding persons.

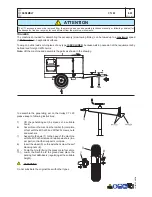

Moving method

The generating sets are lifted with different methods ac-

cording to the unit’s configuration. Below are the main

methods of moving/lifting the genset.

Moving the generating set via forklift

When lifting with a forklift it is necessary to fork the ba-

seframe sideways so that the forks stick out from one

side to the other side, widening them to distribute the

weight properly, maintaining the genset level.

Stickers on the base indicate where to place the lifter

forks.

Transport and handling

!

M

4.2

REV.0-06/10

Moving the generating set via cables or chains

When lifting the genset with the aid of cables or chains it

is necessary to use equipment periodically checked by

a licensed organisation. Hook the cables only on to the

points provided for this use and shown via the appro-

priate stickers.

For correctly moving the generating set:

• DO NOT lift the genset by fastening cables to the lif-

ting eyes on the engine or alternator (these are only

used for lifting the single components).

• DO NOT make abrupt or undulating movements that

pass on stress dynamics to the structure.

• DO NOT leave the generating set suspended for lon-

ger than absolutely necessary to move the unit.

• Use all the lifting eyes provided.

• Use cables and/or chains of equal length so that the

weight is distributed evenly.

02/06/10 M4-GB_COF

Summary of Contents for GE 20 YSX

Page 27: ...Comandi Controls Commandes Mandos GE 20 YSX M 31...

Page 50: ......