Summary of Contents for Ro-V 280

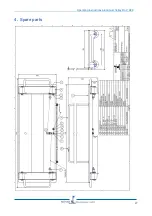

Page 27: ...Operating instructions aluminium trolley Ro V 282 27 4 Spare parts ...

Page 28: ...Operating instructions aluminium trolley Ro V 282 28 ...

Page 29: ...Operating instructions aluminium trolley Ro V 282 29 Risk analysis ...

Page 30: ...Operating instructions aluminium trolley Ro V 282 30 ...