© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

10

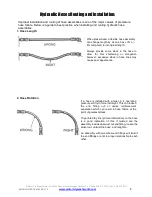

6. Vibration and Flexing

In applications where there is considerable

vibration or flexing, allow additional hose

length.

The metal hose fittings, of course, are not

flexible, and proper installation protects metal

parts from undue stress, and avoids kinks in

the hose

.

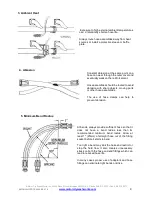

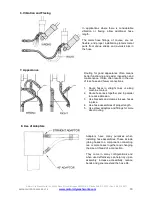

7. Appearance

Routing for good appearance often means

better functioning and easier inspection and

maintenance. It also often results in the use

of less hose and fewer connections

1. Route hoses in straight lines or along

machine contour.

2. Route hose lines together and in parallel

to reduce abrasion.

3. Use brackets and clamps to keep hoses

in place.

4. Use hose assemblies of proper length.

5. Use elbow adaptors and fittings for more

direct routing

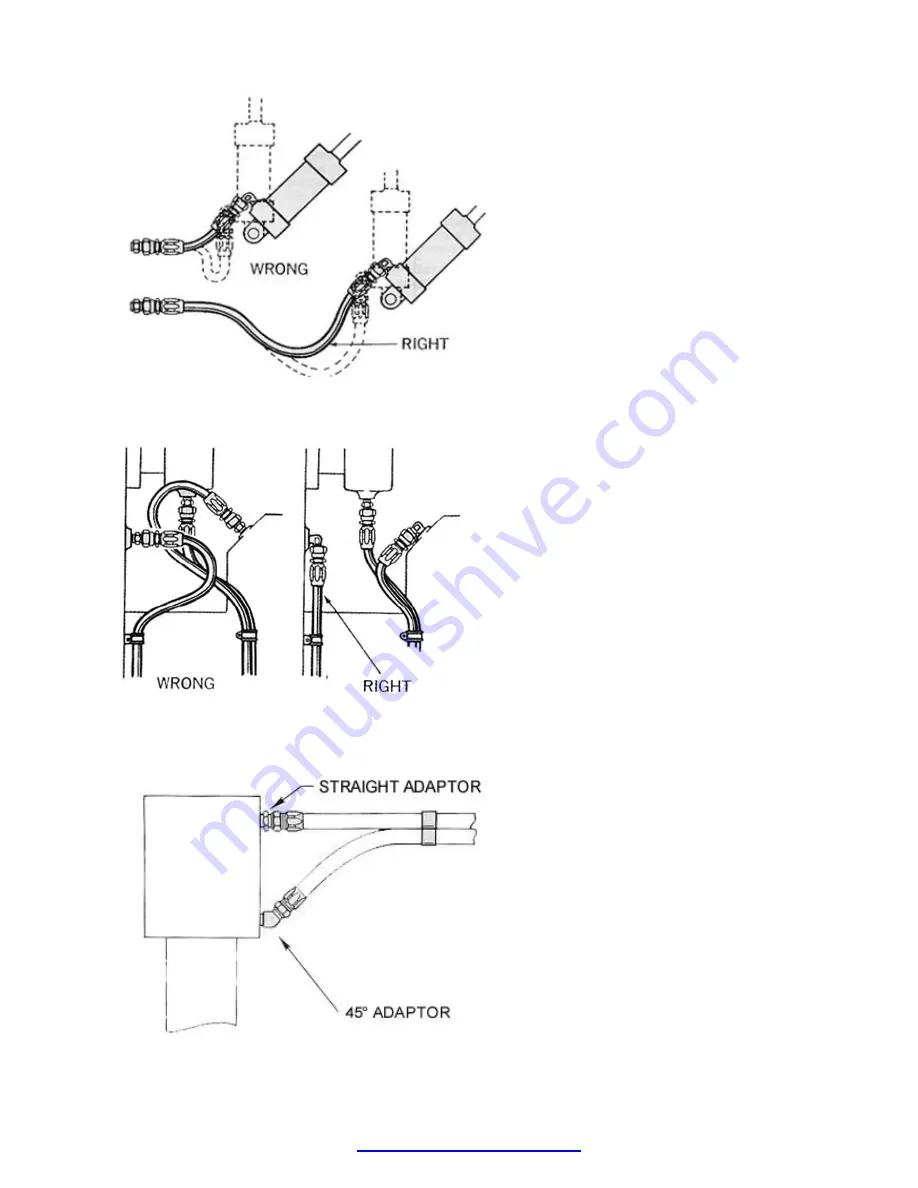

8. Use of Adaptors

Adaptors have many purposes when

installing hose assemblies. These include

joining hoses to a component, connecting

two or more hoses together and changing

the size or thread of a connection.

They come in many configurations and

when used effectively, can help tidy up an

assembly, increase accessibility, reduce

bends and general extend the hose life.