© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

5

Start up new power pack instructions:

Start up new power pack instructions:

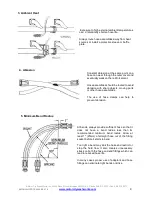

1. Fill tank with ISO 32 Hydraulic oil [Fill to top of sight gauge] *[1]

2. Disconnect the fittings on the lines for the hydraulic motor, hydraulic lines connected together to bypass

hydraulic motor on ALL equipment connected to this power pack to purge new lines.

3. Remove the orange cover to access the motor/pump coupling. [This can be put back on once proper electric

motor rotation has been confirmed]

4. Pump priming filler cap--remove and fill with Hydraulic oil you have used in tank to prime pump--when full

replace cap

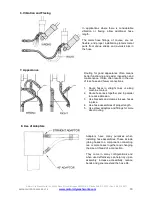

5. Next step is to "BUMP ON" electric motor for no more than 5 seconds to check for correct rotation. [You can look

at coupling or fan on end of electric motor] When you have the correct rotation "arrow on motor is the rotation

direction you want to see the cooling fan move on the electric motor." DO NOT run motor in wrong direction for more

than 15 seconds as this will damage the pump seals.

6. With the proper pump rotation you can now run the pump to push fluid thru lines to remove them of debris for 5

minutes. This will allow the lines to be filled and cleaned to the return filter.

6A. Turn off and reconnect hydraulic motor hydraulic lines then verify proper rotation of Hydraulic motors. If

any are running backwards you need to swap the feed and return line at the hydraulic motor OR at the power pack,

whichever is easiest for you. [If you have only one side running in the wrong direction you will have to swap at the

motor that is spinning wrong.]

7. Calculate the RMP of the brush [count rotations for 15 seconds then multiply by 4]

8.Speed adjustment knob: Loosen jam nut to turn knob. clockwise [slower speed] counterclockwise [faster speed]

9. When done adjusting tighten jam nut to lock knob into place.

10. Save female JIC caps provided from feed and return ports. They are useful for future use.

*[1] If using Water Glycol Hydraulic fluid clean inside of tank

CLEAN

before running pump.

[ONLY SEALED GEAR-MOTOR ASSEMBLIES CAN RUN WITH WATER/GLYCOL BASED FLUID]

*DO NOT RUN OPEN SEAL (BEARING-LESS) GEAR-MOTOR USING

WATER BASED FLUID!

*DOING SO WILL REDUCE THE LIFE OF THE GEAR-REDUCER

AND WILL VOID YOUR WARRANTY!

DESCRIPTION OF PARTS

1.

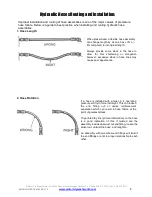

Low level switch:

[dry contact] it is N.O [normally open] or N.C. [normally closed] depending

on the float direction. It can be flipped for opposite operation. It will need to be removed

from tank and it has a cotter pin that needs to be removed to rotate the float bobber that

changes the signal from normally open or normally closed. [typical operation is normally

open] "not sending an input when tank full" [Program input on car wash controller side to

"CRITICAL FAULT" this will disable wash when loss of fluid has happened, protecting the

pump from failing from loss of oil.] Lastly the stem is adjustable and is best used in its highest

position so if there is a leak the float will change states sooner disabling the pump and will

save from losing a lot of fluid.