© Motor City Wash Works, Inc. 48285 Frank, Wixom Michigan 48393 U.S.A.

Phone: 248.313.0272 ▪ Fax: 248. 313.0271

8MANULHYDDOC0004 REV 1.0

www.motorcitywashworks.com

8

Hydraulic Hoses Routing and Installation:

Improper installation and routing of hose assemblies is one of the major causes of premature

hose failure. Below is a guide to best practice when installing and routing hydraulic hose

assemblies.

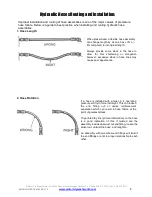

1. Hose Length

When pressurized, a flexible hose assembly

can change length by as much as +3% or -

6% compared to its original length.

Always provide some slack in the hose to

allow for this shortening or elongation

however, excessive slack in hose lines may

cause poor appearance.

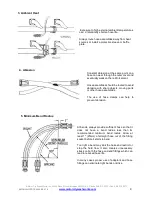

2. Hose Rotation

If a hose is installed with a twist in it, operating

pressure will try to force it straight. This can loosen

the end fitting nut or cause reinforcement

separation which can result in hose failure at the

point of greatest stress.

The printed lay line (printed information) on the hose

is a good indication of this. If twisted and the

assembly includes a swivel nut end fitting, loosen the

swivel nut, untwist the hose, and retighten.

An assembly with two elbow end fittings will twist if

the end fittings are not in proper relationship to each

other.