20A

20B

78

77

76

74

75

B

C

A

A

A

A

EN

EN

Belt

Belt

06. MAINTENANCE

06. MAINTENANCE

Attention:

First, check the tightening of the screws (A). These screws keep the turnbuckles of

the belt fixed. If these screws lose strength, the belt may lose tension.

A long period of door maneuvers can lead to an alteration on the belt tension. For this rea-

son it is recommended a belt tension periodic review to ensure the normal operation of the

door.

It is recommended a full periodic check to ensure the normal operation of the door. This

review can only be performed by qualified technicians in handling automatic glass doors.

Check the following points during the review:

01.

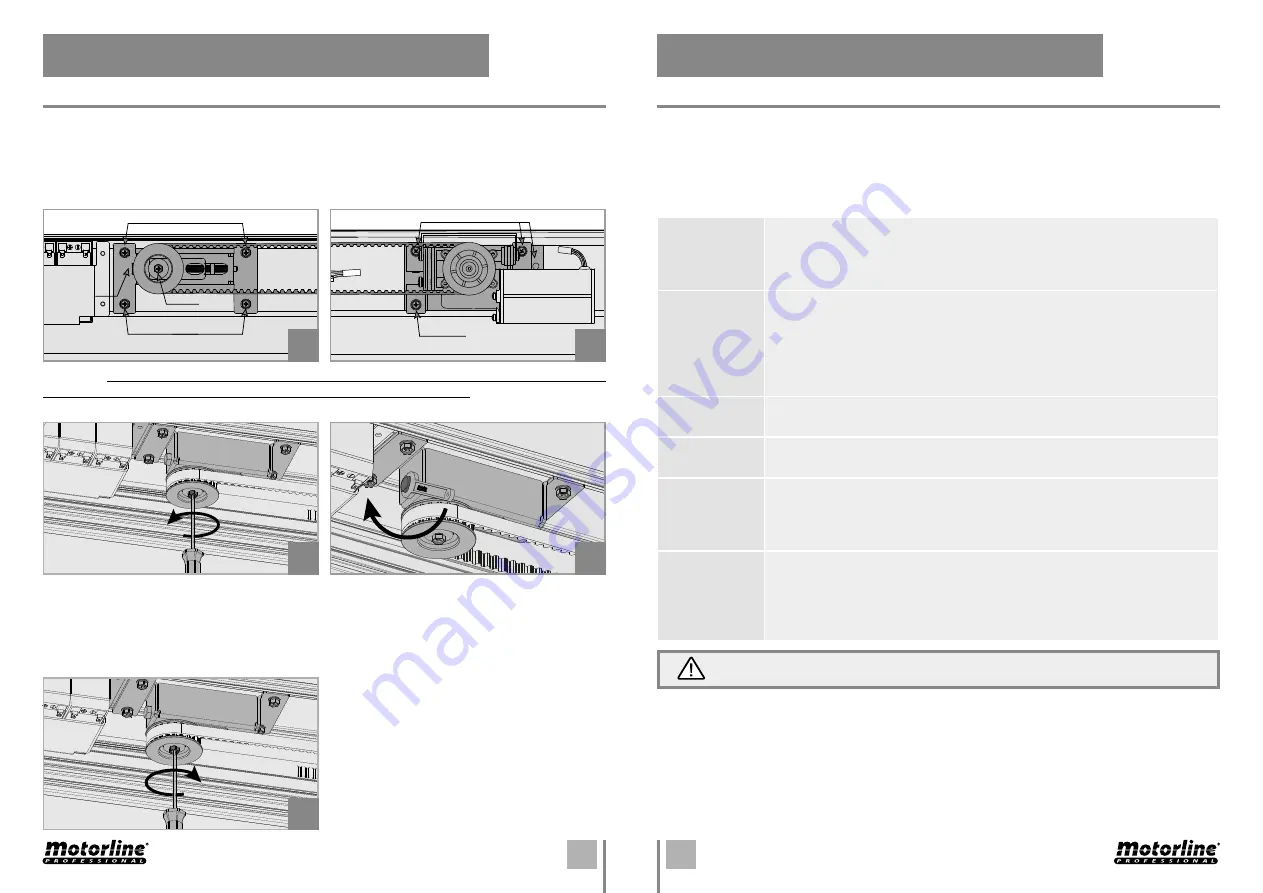

To start the belt tension adjustment,

loosen first, the screw (

C

). When this screw is

tightened, it locks the bolt (

B

), preventing it

of losing strength.

02.

Turn the screw (

B

) to increase or decrease

the belt tension. To find out if the voltage is

properly adjusted, press the belt at middle

position, the top against the bottom. These

should not be able to touch each other.

03.

Tighten the screw (

C

) to finish the setting.

BELT

OTHER INFORMATION

• BELT TENSION ADJUSTMENT

• VERIFICATIONS

• ELIMINATION

At the end of its working lifetime, all components must be removed from the place by a

qualified installer who must take into account all precautions and safety measures during

the procedure.

Never place the components in domestic waste or uncontrolled landfills because they

would contaminate the environment. These must be deposited into appropriate recycling

containers, to be separated according to their materials.

Before performing any operation on the door is required to turn off the electric

current.

General

Leveling of the automation;

Automation grip to the surface;

Cable wrapping;

Review label;

Leaves

Noise from the carts;

Gap in anti-derailment system;

Alignment of the leaves;

Gap inside the guides;

Carts and rail cleanness;

Stoppers adjustment;

Belt

Belt tension;

Belt wear;

Motor

Noise in the motor;

Motor's connection cables;

Control board

Cleaning insects;

Power protected by circuit breaker and ground wire;

Door's speed / strength;

Motor's connection cables;

Components

Selector's functioning;

Radar's response and range;

Photocells functioning;

Photocells alignment;

Eletric lock and unlocking crank functioning;