12A

12B

EN

EN

All tests must be performed by qualified personnel due to serious danger associated

with the misuse of electrical systems!

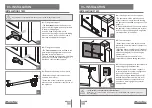

AUTOMATISM

8μF (230V) / 20μF (110V)

Capacitor

1

2

3

2

COM 1

COM 2

COM

Ground Wire

Phase 2

Phase 1

Open

Close

Motor

Power Supply 1

Power Supply 2

To detect if the malfunction is on the control board or on the motor is, sometimes, necessary

to perform tests with connection directly to a 110V/230V power supply.

For this, it is necessary to interpose a capacitor on the connection in order to the automatism

to work (check the type of capacitor to be used in the product manual). The diagram below,

shows how to make that connection and how to merge the different components wires.

01

•

Connect the power wires to the terminal, as shown below.

02

•

Connect the automatism wires in the terminal, interposing a capacitor in the opening

and closing wires.

03

•

Once these connections are completed, connect to a 110V/230V power outlet, depending

on the motor/control board in test.

NOTES:

•

To perform the tests, there is no need to remove the automatism from the place it is installed,

because in this way, it is possible to understand if the automatism can function properly

connected directly to the current.

•

You should use a new capacitor during this test to ensure that the problem does not lie on it.

All tests must be performed by qualified personnel due to serious danger associated

with the misuse of electrical systems!

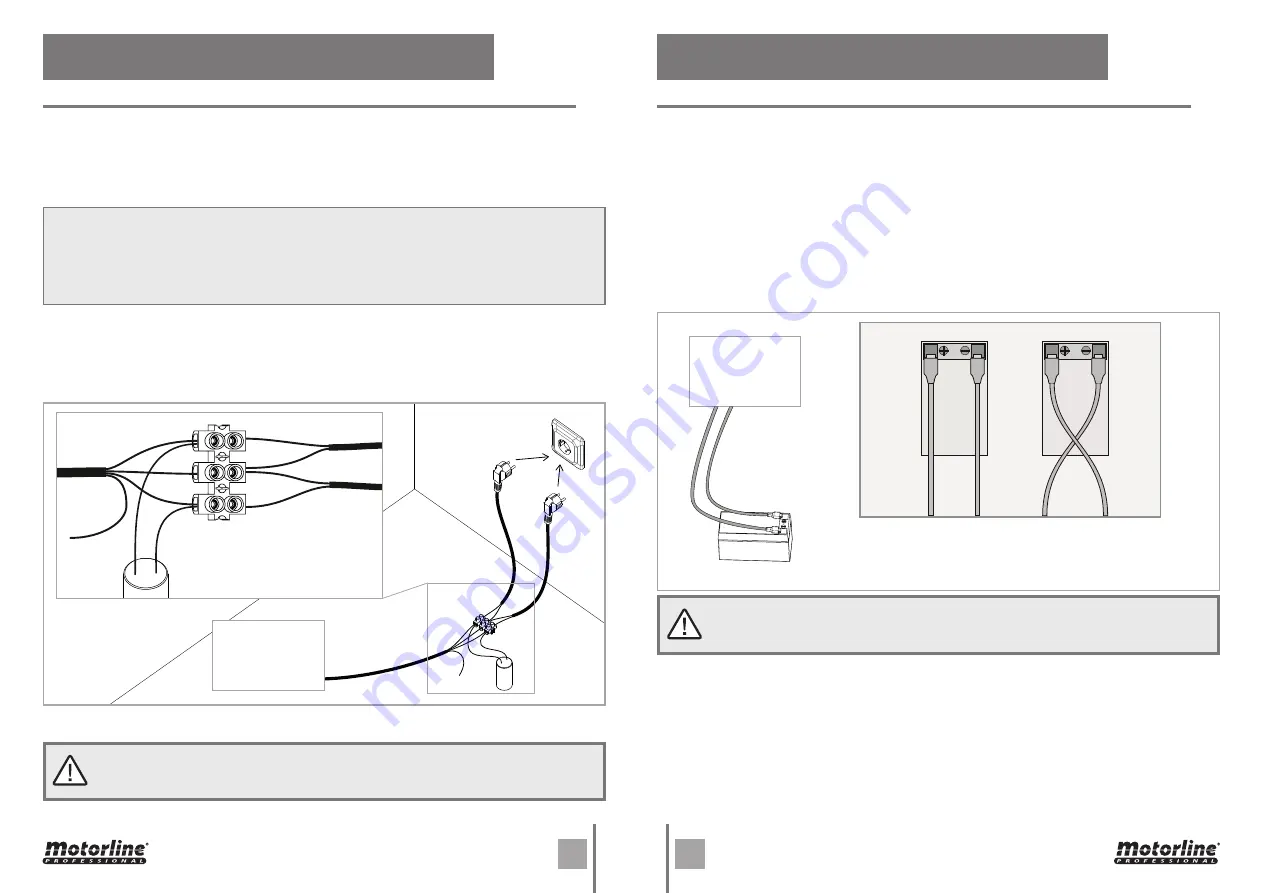

To detect which are the components with problems in a 24V LINCE automatism instalation,

it's sometimes necessary to run a test directly to a external power supply (another 24V

battery).

The diagram below shows how to connect the motor to the battery.

NOTES:

• To make these tests it isn't necessary to remove it from the location where it is installed,

because in this way, you can understand of the automatism works properly directly

connected to the external battery.

• Once you connect the wires to a battery 24V, the motor must work for one direction. To test

the opposite movement, change the position of the wires connected to the battery.

06. COMPONENTS TEST

06. COMPONENTS TEST

230V/110V MOTOR

24V MOTOR

AUTOMATISM

24V Battery

24V Battery

Motor rotates

to one direction

(eg: right)

Motor rotates in the

opposite direction

(eg: left)

24V Battery

Motor's wires