6A

6B

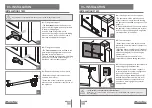

962mm || 1162mm || 1562mm

647mm || 747mm || 947mm

175mm

159mm

104mm

A

A

B

B

A

?

mm

B

A-

10mm

17

18

EN

EN

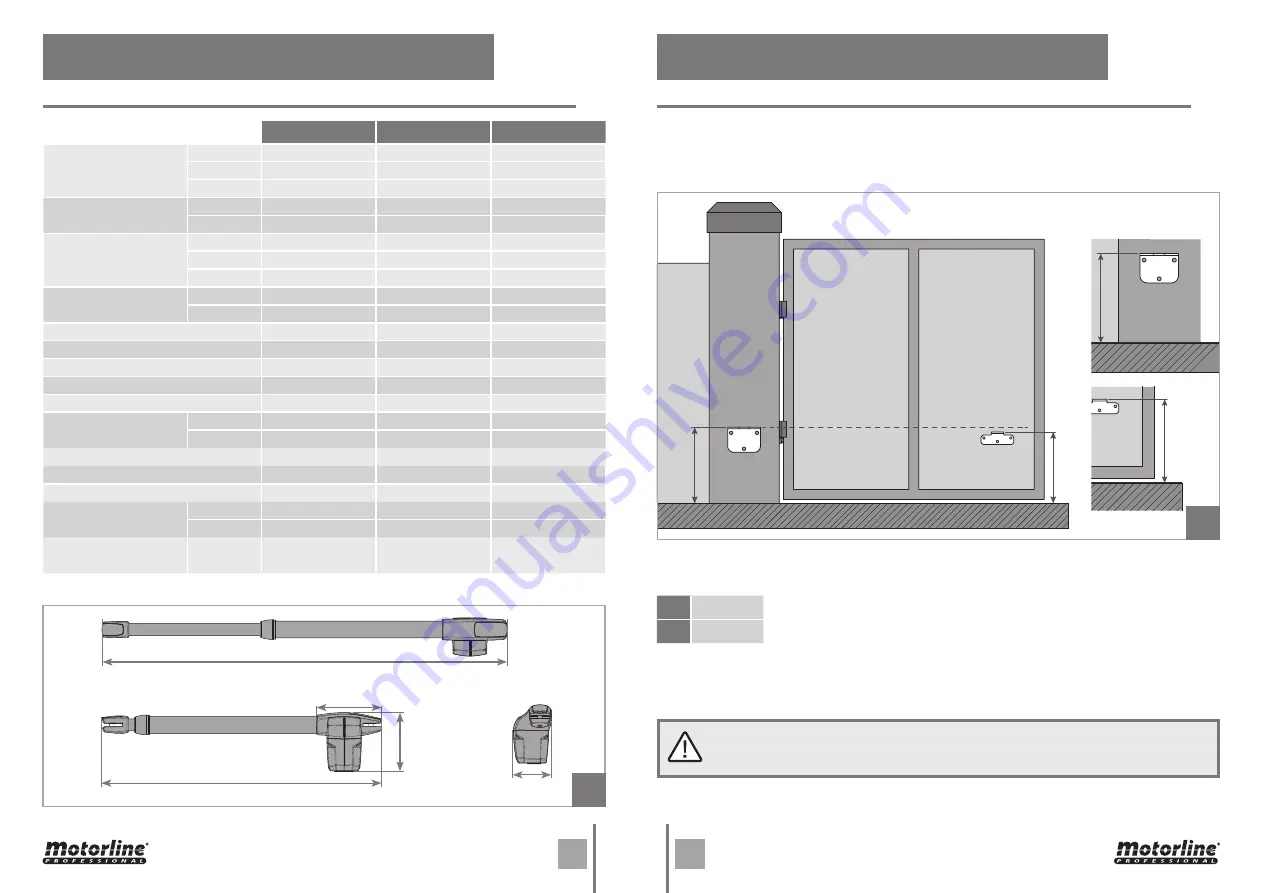

The operator

LINCE

must be installed with a small inclination , to prevent water infiltration

through the extension arm.

For this, the front support must be fixed to the gate with a height lower than the height of

the rear support. See example below:

Example:

• If the height of the rear bracket (

dimension A

)is set at 600 mm, then the height of the front

bracket (

dimension B

) will be 590 mm (600mm-10mm).

Dimension A

•

Vertical distance

from the floor to the top of the rear support .

Dimension B

•

Vertical distance

from the floor to the top of the front support.

• Set

dimension A

(this can be any size of your choice).

• After you set

dimension A

, subtract

10mm

to find

dimensionB

.

LINCE 300

||

400

||

600

dimensions are the following:

It is very important that these dimensions are respected!

Only this way can be assured

the correct functioning and durability of the operators!

It is also very important to have a levelled ground/terrain!

LINCE300

LINCE400

LINCE600

•

Power Supply

230V

230Vac 50/60Hz

230Vac 50/60Hz

230Vac 50/60Hz

110V

110Vac 50/60Hz

110Vac 50/60Hz

110Vac 50/60Hz

24V

24Vdc

24Vdc

24Vdc

•

Power

230/110V

230W

230W

230W

24V

60W

60W

60W

•

Current

230V

1,3A

1,3A

1,3A

110V

2,5A

2,5A

2,5A

24V

1A to 3A

1A to 3A

1A to 3A

•

RPM

230/110V

1400 RPM

1400 RPM

1400 RPM

24V

1600 RPM

1600 RPM

1600 RPM

•

Noise level

LpA <= 50 dB (A)

LpA <= 50 dB (A)

LpA <= 50 dB (A)

•

Force

2300N

2300N

2300N

•

Operating temperatures

-25°C to 65°C

-25°C to 65°C

-25°C to 65°C

•

Thermal protection

120°C

120°C

120°C

•

Protection class

IP54

IP54

IP54

•

Working frequence

230/110V

25%

25%

25%

24V

Intensive

Intensive

Intensive

• Opening time

8 sec. to 13 sec.

13 sec. to 18 sec.

20 sec. to 28 sec.

•

Course

300mm

400mm

600mm

•

Max leaf length

2500mm

3000mm

4000mm

•

Capacitor

230V

8µF

8µF

8µF

110V

20µF

20µF

20µF

•

Opening speed

230V

20mm/s

20mm/s

20mm/s

24V

23,5mm/s

23,5mm/s

23,5mm/ss

03. OPERATOR

04. INSTALLATION

TECHNICAL SPECIFICATIONS

HEIGHT OF THE SUPPORTS