19A

19B

18A

18B

EN

EN

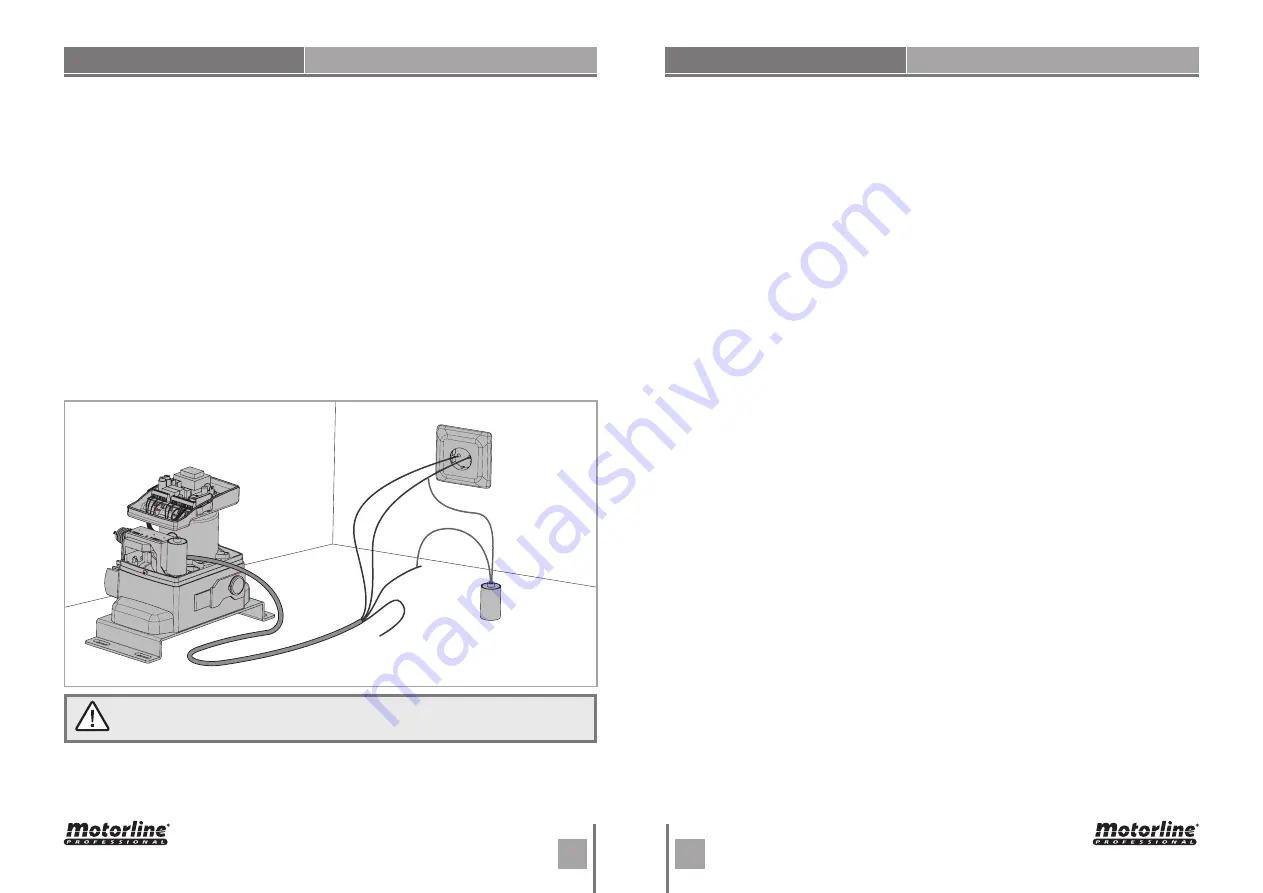

To detect which components have problems during a sliding automatism installation,

sometimes it's necessary to conduct tests with a direct connection to a 230V power

supply. For this, it's necessary to interpose a capacitor on the connection so that the

motor can work (check the capacitor type to be used in the product's manual). In the

below diagram is shown how this connection must be made and how to merge the

different component wires.

NOTES:

• To perform the tests you don't need to remove the automatism from it's place, because

this way you can understand if the automatism, directly connected to the power, can

function correctly.

• The order of capacitor wires linked with the automatism wires are not important, as

long as you link, one to the Brown wire and the other to the Black one;

• The common wire of the motor must always be connected to the power supply;

• To reverse the automatism functioning direction, switch the Black wire with the Brown

wire of the automatism.

All tests must be performed by skilled technicians due to serious danger

associated with the misuse of electrical systems!

CAPACITOR

MOTOR

230V POWER

SUPPLY

Ground wire

Brown

Black

Common(Blue)

In the position corresponding to each transmitter input in low voltage, the control board has

a LED to identify the condition of it. The LED on indicates that the input is closed, while the

LED off indicates that the input is open.

CAPACITOR SCHEME

INPUTS TEST

07. COMPONENTS TEST

07. COMPONENTS TEST