4A

4B

8

4

1 2 3

9

6

12

5

8 9

7

11

10

430

358

40

313,10

348,20

166,85

165

83,77

95

60

50

6

5

7

8

9

15

12

13

4

3

2

1

14

11

10

EN

EN

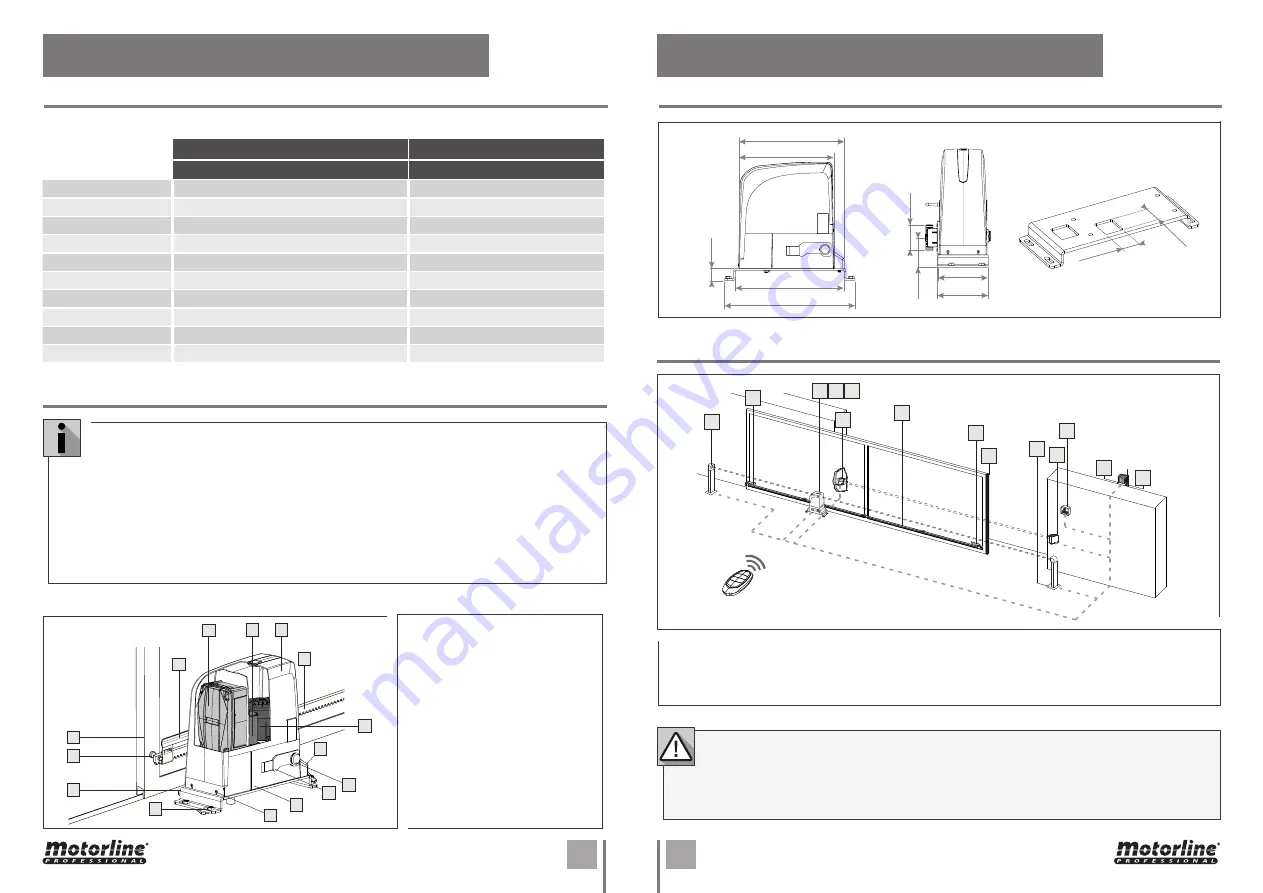

02. OPERATOR

TECHNICAL SPECIFICATIONS

DIMENSIONS

02. OPERATOR

Technical specifications of the automated operator:

DESCRIPTION

DESCRIPTION OF THE SYSTEM

1 •

Gate

2 •

Rack spacer

3 •

Foundation plate

4 •

Fixation screw

5 •

Limit switch plate

6 •

Control box

7 •

Capacitor

8 •

Cover

9 •

Rack

10 •

Motor

11 •

Protective cover

12 •

Lock

13 •

Manual release

14 •

Housing

15 •

Screw

1 •

Motor

2 •

Control board

3 •

Receiver

4 •

Left limit switch plate

To lay down electric cables, use rigid and/or flexible adequate tubes.

2) To avoid any kind of interference, always separate low voltage connection cables from AC110V

power cables.

3) The description of system is standard system, but we did not provide all parts. If you want

system accessories, please contact us.

5 •

Right limit switch plate

6 •

Rack

7 •

Key selector

8 •

Photocell column

9 •

Safety photocells

10 •

Antenna

11 •

Warning light

12 •

Safety edge

•

Automated system for residential or industrial sliding gates with a maximum of 2000kgs.

It consists of a reversing electro-mechanical gearmotor, powered by a 110V control unit.

•

The automated system houses a programmable electronic control board that enables setting of

function logics, work time and pause time, anti-crushing sensitivity as well as partial-opening

width.

•

The reversing system guarantees the gate will automatically lock when the motor is not

operating.

•

A release system enables the gate to be moved by hand in case of malfunction or emergency.

•

The automated system was designed and built for controlling sliding gates. Do not use for any

other purpose.

OL1500

OL2000

110V

110V

• Power supply

110V, 60Hz

110V, 60Hz

• Rated absorbed power

550W

1000W

• Max speed

186mm/snd

186mm/snd

• Noise

≤ 56dB

≤ 56dB

• Operating temperature

>-25ºC , <65ºC

>-25ºC , <65ºC

• Protection class

IP44

IP44

• Thermal protection (

˚C

)

120˚C

120˚C

• Leaf max weight (Kg)

1500Kg

2000Kg

• Working frequency

70%

70%

• Capacitor

60μF

25μF and 70μF