7A

7B

DIN912

M5x10

A

-

+

EN

EN

03. INSTALLATION

INSTALLING THE RACK

CLUTCH ADJUSTMENT

03. INSTALLATION

6 •

Pull another element of the rack above, using a piece of additional rack teeth to synchronize the two

elements (Fig. 22).

7 •

Use a level again to make sure that rack is perfectly level.

8 •

Manually move the gate and carry out the operations of attachment such as with the first element,

proceeding up to the end of the gate.

1 •

After having rack

nstalled, take the gate

back to the closed

position and position

the limit swicth plate on

the rack. In this closed

position, the plate should

trigger the limit switch of

the motor.

2 •

Tighten the screws

DIN912 M5x12 included in

the pack, until it touches

the rack, squeezing it.

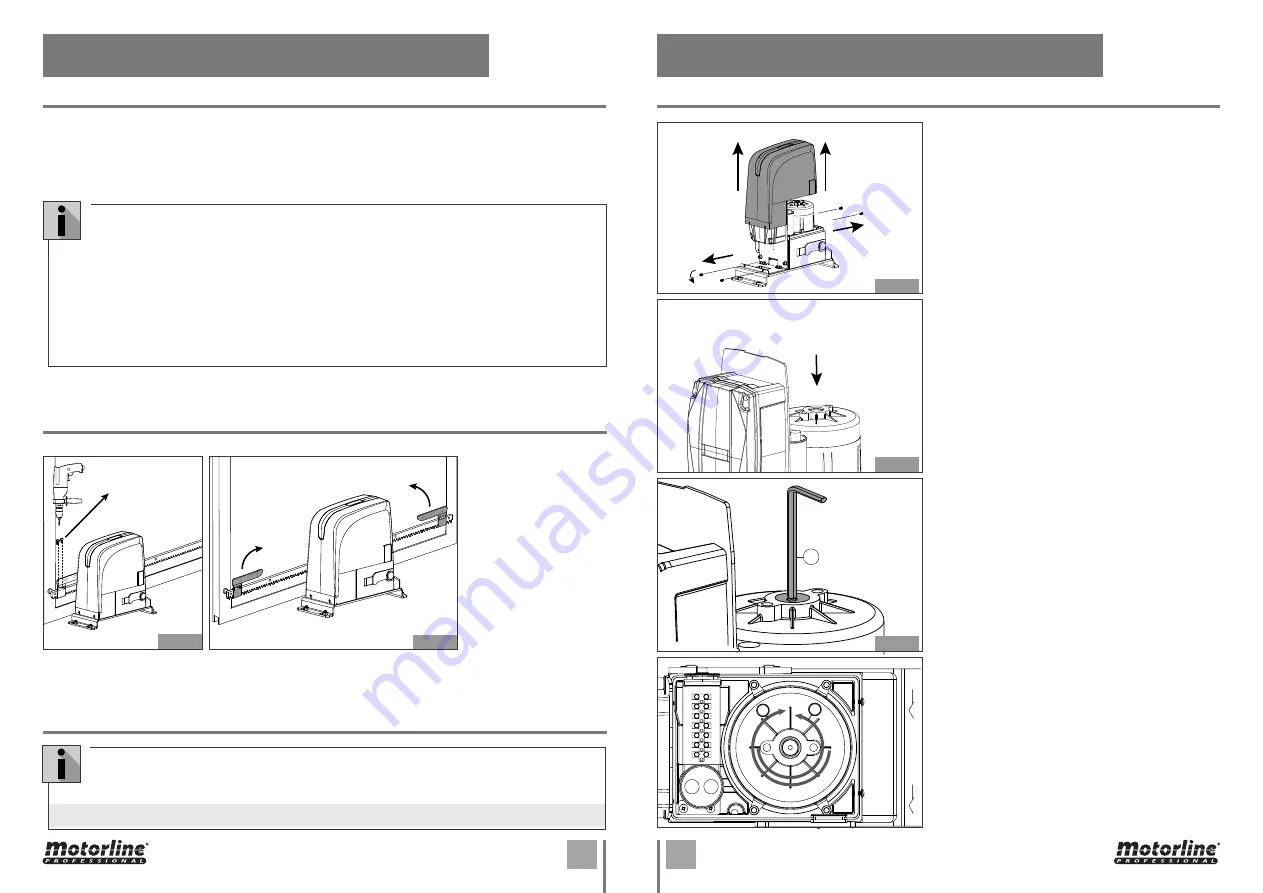

1 •

Unbolt the screws and remove the cover.

2 •

Access the adjusting screw. Slide the central box

forward.

3 •

Adjust the screw in the upper part of the engine.

To do this, it will require a 6mm umbrako key as

shown in the image (A).

4 •

Do a test to the motor’s irreversibility. To do that,

just move the gate manually. If the gate is moving, it is

necessary to refine the screw by turning clockwise (+).

If the gate does not move at idle, it means that the

screw is tightened too much. Turn it counterclockwise

(-) until the engine moves the gate at idle.

The tuning must achieve a balance between the gate ‘s

irreversibility and the engine’s power.

INSTALLING LIMIT SWITCH PLATE

MAINTENANCE AND REPAIRS

•

This motor can work with all types of racks.

•

When installing nylon rack, make the application following the same steps described in the

previous paragraphs. Start by placing the gate in the closed position, support the first meter

of rack pinion on the engine and keeping it level horizontally, screw the first screw. Go opening

the gate and tightening the remaining bolts. Continue adding more rack parts and repeating

the same steps to complete the installation.

•

Make sure that, during the gate travel, all the rack elements mesh correctly with the pinion.

•

Do not, on any occasion, weld the rack elements either to the spacers. For fixing these, use

screws and washers like in the Fig.20.

•

Do not use grease or other lubricants between rack and pinion.

Carry out the following operations at least every 6 months:

•

Check the efficiency of the release system.

•

Check the efficiency of the safety devices and accessories.

• For any repairs, pls contact the authorised repair centers.

Fig. 25

Fig. 26

Fig. 27

Fig. 28

Fig. 23

Fig. 24

3 •

Move the gate to the open position and repeat the same process for the other limit switch plate.

4 •

The limit switch plates should be installed as in

Fig. 24

.

left

right