2-6

SE4400 Integration Guide

Commercially Available Coatings

Anti-Reflection Coatings

Anti-reflection coatings can be used for stray light control or to achieve maximum working

range, and can be applied to the inside and/or outside of the window to reduce the amount

of light reflected off the window back into the engine. However, they are expensive and

have very poor abrasion and scratch resistance.

Polysiloxane Coating

Polysiloxane type coatings are applied to plastic surfaces to improve the surface resistance

to both scratch and abrasion. To apply, dip and air dry in an oven with filtered hot air.

To gauge a window's durability, use ASTM standard D1044, Standard Test Method for

Resistance of Transparent Plastics to Surface Abrasion (the Taber Test), which quantifies

abrasion resistance as a percent increase in haze after a specified number of cycles and

load. Lower values of the increase in haze correspond to better abrasion and scratch

resistance. See

.

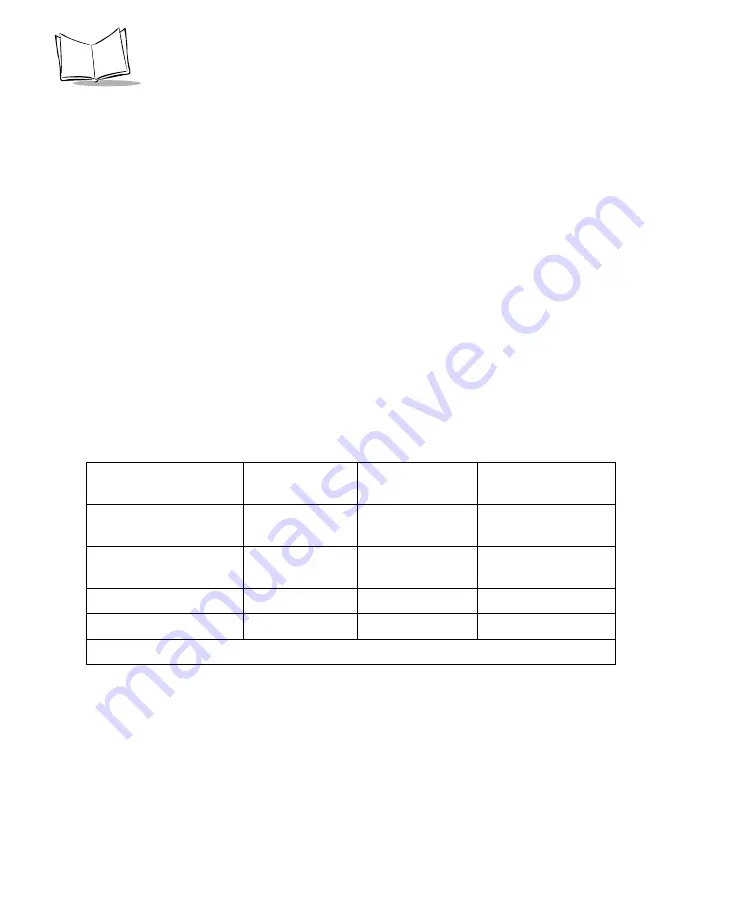

Table 2-2. Taber Test Results on Common Exit Window Materials

Sample

Haze 100 cycles

Haze 500 cycles

Abrasion

Resistance

Chemically Tempered

Float Glass

1.20%

1.50%

Best

PMMA with Polysiloxane

Hardcoat

3%

10%

ADC

5%

30%

PMMA

30%

Worst

* All measurements use a 100 gram load and CS-10F Abraser.

Summary of Contents for Symbol SE4400

Page 1: ...SE4400 Integration Guide ...

Page 2: ......

Page 3: ...SE4400 Integration Guide 72E 63399 04 Revision A January 2007 ...

Page 6: ...iv ...

Page 9: ...vii Contents Index Feedback ...

Page 10: ...viii SE4400 Integration Guide ...

Page 48: ...3 22 SE4400 Integration Guide ...

Page 78: ...5 20 SE4400 Integration Guide ...

Page 90: ...Index 4 SE4400 Integration Guide ...

Page 92: ......

Page 93: ......