47

MCTC manual

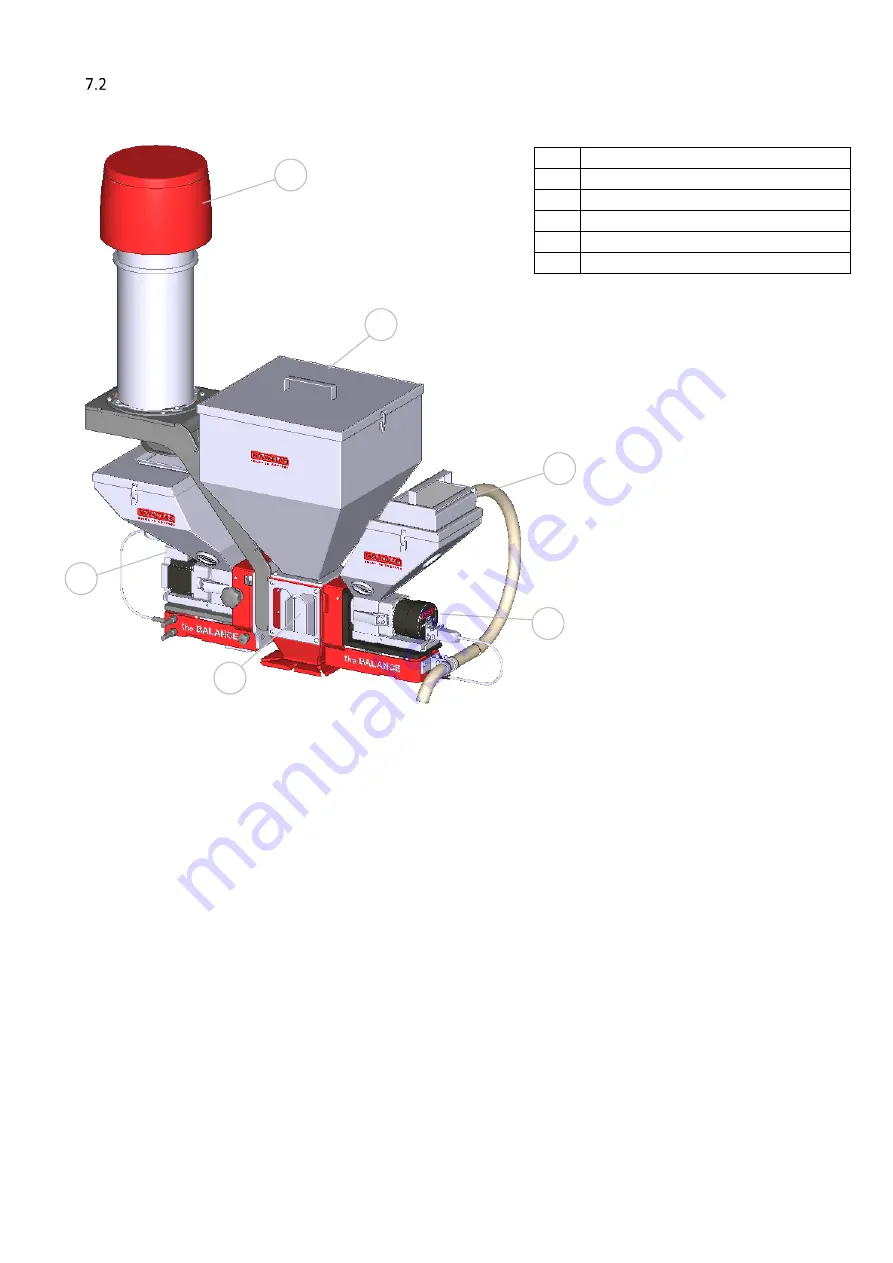

Closed loop

Hardware example

Working principle

At system start, the regrind unit starts loading regrind from the grinder into the dosing unit hopper. If no

regrind or insufficient regrind is available, the unit will repeat the loading sequence with a time interval.

During this wait time, the regrind unit is not dosing. The color unit is dosing its nominal amount of color.

When sufficient regrind is loaded the regrind unit starts dosing, the dosing amount of the color unit is

lowered according to the level of regrind added.

If during processing the level of regrind in the hopper slowly increases, the regrind dosing will be increased

automatically. The color dosing is lowered according to the amount of regrind dosed to maintain constant

coloring. When no process disturbance occur, the system will continue running in this state.

If for some reason the amount of regrind fed to the regrind dosing unit increases (an operator fills the bin of

the grinder manually) the regrind unit will increase its dosing.

In case no regrind is available anymore, the regrind unit stops and attempts to load material with a time

interval. The nominal regrind percentage is the weight part of the sprue / runner.

Closed loop configuration requires a MV, ME, MFD or 3PH hopper loader to be used with the regrind dosing unit.

1

Single phase motor loader (MFD)

2

Regrind dosing system

3

Main material hopper

4

Neckpiece with regrind insert

5

Color dosing system

6

ME loader system

1

2

3

4

5

6