2

w w w. m o x a . c o m

i n f o @ m o x a . c o m

Industrial I/O

Efficient Ethernet Device Connectivity

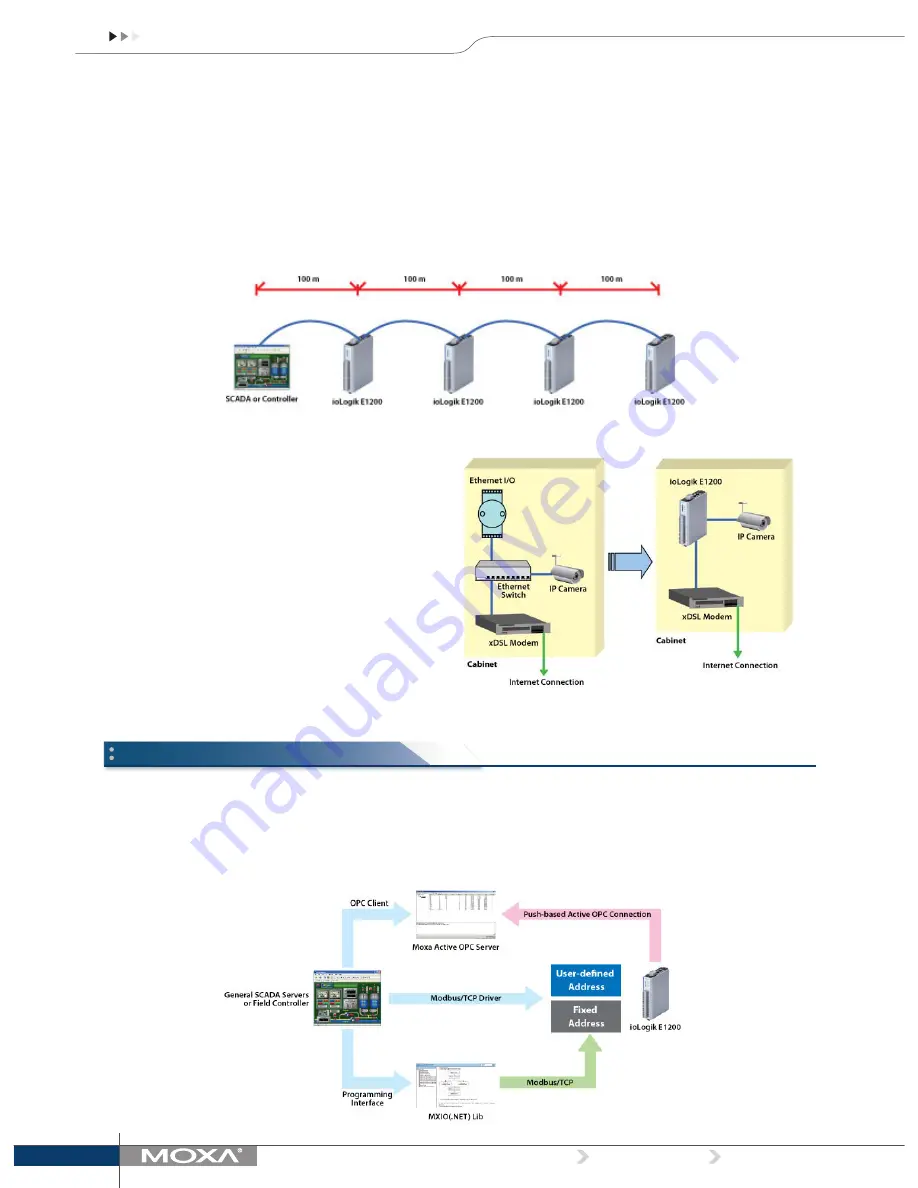

The ioLogik E1200’s built-in Ethernet switch ports can be cascaded

to other Ethernet devices at the same location. A typical situation is a

remote site that has a few sensors, devices, and Internet connectivity.

Take a roadside cabinet as an example. The IP camera monitors

activity on the street and an Ethernet I/O device handles environmental

monitoring, intrusion, and alarms, and triggers the camera to take

snapshots when needed.

The traditional approach for this kind of remote monitoring application

requires an additional switch or hub for connecting the Ethernet I/O

device to the IP camera. A better approach is to connect another

Ethernet device such as a PLC controller or an IPC in the same cabinet

and use the industrial switch embedded in the ioLogik E1200. Not only

does this solution reduce the number of failure points associated with

an additional switch or hub, but it also reduces the amount of wiring

needed for power, signals, and the network. Space inside the cabinet

can also be saved.

Daisy-chained Ethernet I/O Connection

A new daisy-chained Ethernet I/O concept is now available. The ioLogik

E1200 industrial remote Ethernet I/O has two embedded Ethernet

switch ports that allow information to flow to another local Ethernet

device or connect to the next ioLogik in the daisy-chain. Applications

such as factory automation, security and surveillance systems, and

tunnel monitoring, can make use of daisy-chained Ethernet for building

multi-drop I/O networks over standard Ethernet cables. Many industrial

automation users are familiar with the multi-drop configuration

typically used in fieldbus applications. The daisy-chain function on the

remote Ethernet I/O ioLogik E1200 not only increases the connection

between machines and panels, but also lowers the cost of buying

separate Ethernet switches, and at the same time reduces labor fees

and cabling by a large percentage. For example, if a production facility

contains 700 stations (20 points per station), the wiring cost reduction

can reach 15% of the total implementation cost.

Several approaches are available for controlling the ioLogik E1200

over an Ethernet network. As a traditional I/O solution, the ioLogik

E1200 allows a central SCADA system or field controller to poll the I/O

channel status via the standard, open Modbus/TCP protocol. Except

for the default fixed Modbus/TCP address, the ioLogik E1200 provides

the capability of letting users define the address by themselves. In

Smart I/O Connectivity

addition, the MXIO(.NET) library makes it easy for programmers to

integrate their own software to the ioLogik in the field. Moreover, the

ioLogik E1200 can leverage the benefits of the active technology of

the ioLogik E2000 series with the free Active OPC Server package to

seamlessly connect to any Windows-based SCADA system.